Pultruded Grating

- Home

- Products

- FPR Greating

- Pultruded Grating

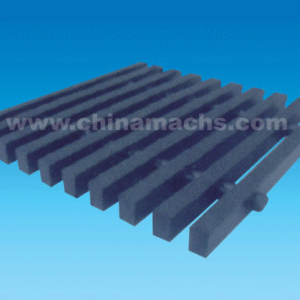

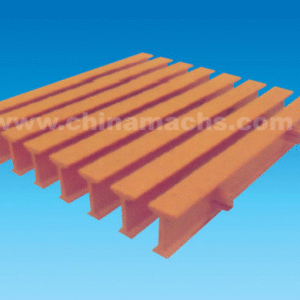

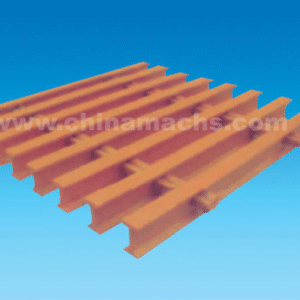

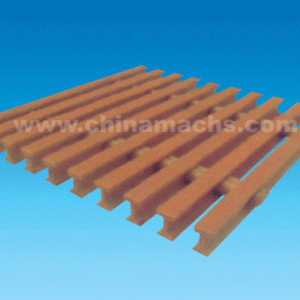

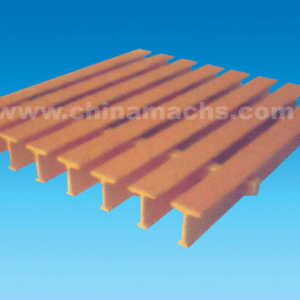

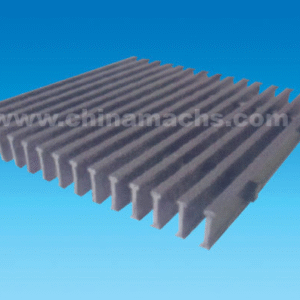

Pultruded FRP Grating is made by pulling continuous fiberglass rovings through a resin bath and heated die, forming high-strength load-bearing bars. It offers superior strength-to-weight ratio, excellent corrosion resistance, and long service life for demanding industrial environments.

Machs is a trusted expert in FRP grating manufacturing with over 20 years of industry experience. Our pultruded FRP grating is engineered for industrial walkways, platforms, and environments exposed to corrosion. Available in multiple sizes, colors, and surface options, our products combine high strength, durability, and chemical resistance to meet the demands of harsh operating conditions.

Product Range

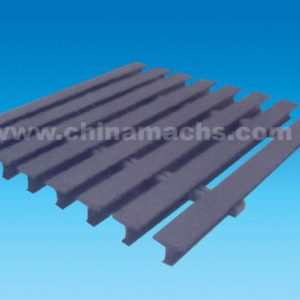

Our Pultruded FRP Gratings are designed for heavy-duty industrial walkways, platforms, and trench covers. Available in a wide range of depths, open areas, and colors, they provide excellent strength-to-weight ratio, superior corrosion resistance, and slip-resistant surfaces. Ideal for chemical plants, wastewater treatment facilities, and other demanding environments.

Heavy Duty 1 1/2″ Deep 50% Open(HD 15-50)

FRP GratingHeavy Duty 1 1/2″ Deep 40% Open(HD 15-40)

FRP GratingHeavy Duty 1″ Deep 60% Open(HD 10-60)

FRP GratingHeavy Duty 1″ Deep 50% Open(HD 10-50)

FRP GratingHeavy Duty 1″ Deep 40% Open(HD 10-40)

FRP Grating

T-Bar 3″Deep 60%Open(I30-60)

FRP GratingT-Bar 3″Deep 50%Open(I30-50)

FRP GratingT-Bar 3″Deep 40%Open(I30-40)

FRP GratingT-Bar 2″Deep 33%Open(T20-33)

FRP GratingT-Bar 1 1/2″Deep 60%Open(I15-60)

FRP GratingT-Bar 1 1/2″Deep 50%Open(I15-50)

FRP GratingT-Bar 1 1/2″Deep 40%Open(I15-40)

FRP GratingT-Bar 1/4″Deep 40%Open(I12-40)

FRP GratingT-Bar 1″Deep 60%Open(I10-60)

FRP GratingT-Bar 1″Deep 50%Open(T10-50)

FRP GratingT-Bar 1″Deep 40%Open(T10-40)

FRP GratingT-Bar 1″Deep 50%Open(T10-50)

FRP Grating

Fiberglass Pultruded Grating

FRP GratingPedestrian Pultruded Grating

FRP GratingT-Bar 1 1/2″Deep 33%Open(T15-33)

FRP GratingT-Bar 1″Deep 50%Open(T10-50)

FRP GratingT-Bar 1″Deep 35%Open(T10-35)

FRP GratingT-Bar 1″Deep 18%Open(T10-18)

FRP GratingT-Bar 1 1/2″Deep 60%Open(IP15-60 ADA)

FRP GratingT-Bar 1 1/2″Deep 17%Open(T15-17)

FRP GratingT-Bar 1″Deep 33%Open(T10-33)

FRP GratingT-Bar 1 1/2″Deep 17%Open(T15-17)

FRP GratingT-Bar 1″Deep 60%Open(T10-60 ADA)

FRP Grating

Key Features: Pultruded vs. Molded Grating

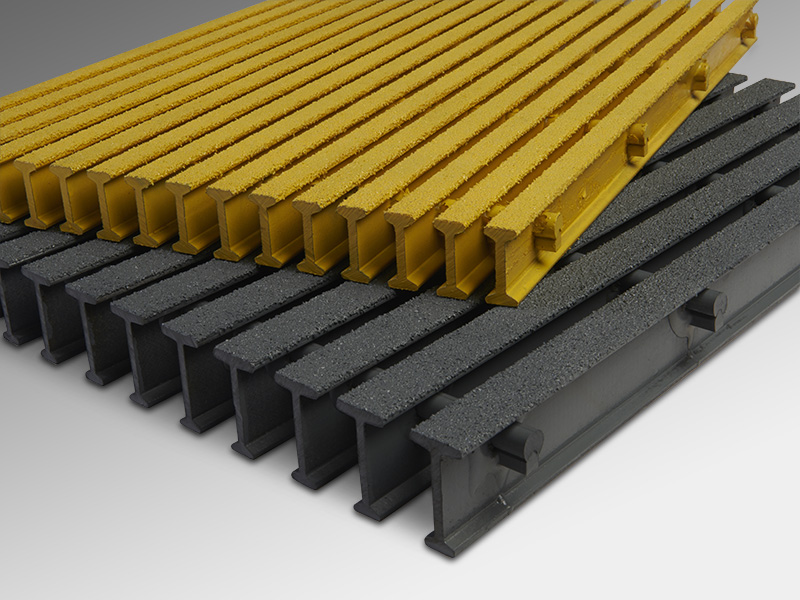

Pultruded FRP grating offers higher strength and longer spans than molded grating. Its continuous fiberglass rovings and I/T-bar design give it superior load capacity and stiffness in the bearing bar direction, making it ideal for heavy-duty walkways and platforms. Compared with molded grating, it is lighter, has better directional strength, and supports more custom sizes and open area options.

Applications

Pultruded FRP Gratings are widely used in walkways, platforms, trench covers, mezzanines, and stair treads across chemical processing, marine, wastewater treatment, food & beverage, and oil & gas industries.

Customization process

Ready to start customizing your pultruded gratings? Here’s our step-by-step customization process.

Requirements

Tell us size, type, color, and quantity.

Design & Quote

We confirm specs and send you a quote.

Production

Gratings are manufactured with strict QC.

Delivery

Secure packaging and fast global shipping.

Pultruded Grating - FAQS

Q1: What is the difference between pultruded and molded FRP grating?

Pultruded grating has higher glass content and directional strength, making it ideal for long spans and heavy loads, while molded grating is isotropic and better for areas needing frequent cutouts.

Q2: Can I customize the size and color of my grating?

Yes. We offer a wide range of bar shapes, depths, panel sizes, and colors (grey, yellow, green) to meet your project requirements.

Q3: Is pultruded grating slip-resistant?

Yes. You can choose a grit surface for maximum slip resistance or a smooth surface for easy cleaning.

Q4: How strong is pultruded grating compared to steel?

It provides a high strength-to-weight ratio, is about one-third the weight of steel, and resists corrosion, making it easier to install and maintain.

Q5: What industries commonly use pultruded grating?

It’s widely used in chemical plants, wastewater treatment facilities, offshore platforms, food processing areas, and other corrosive environments.