Molded Grating

- Home

- Products

- FPR Greating

- Molded Grating

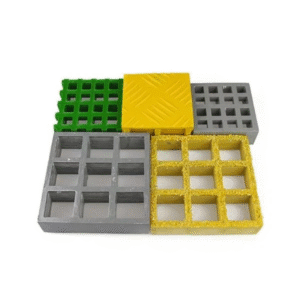

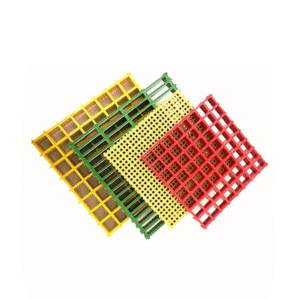

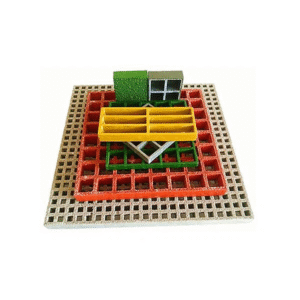

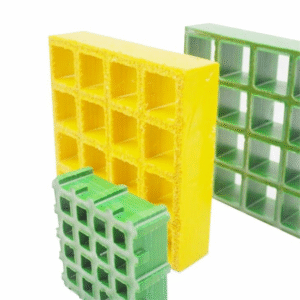

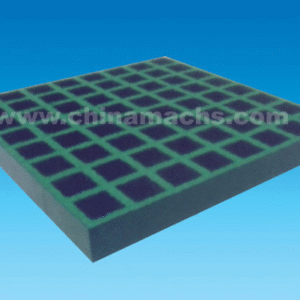

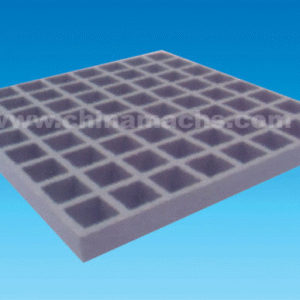

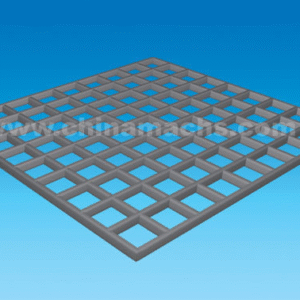

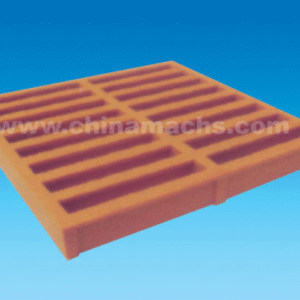

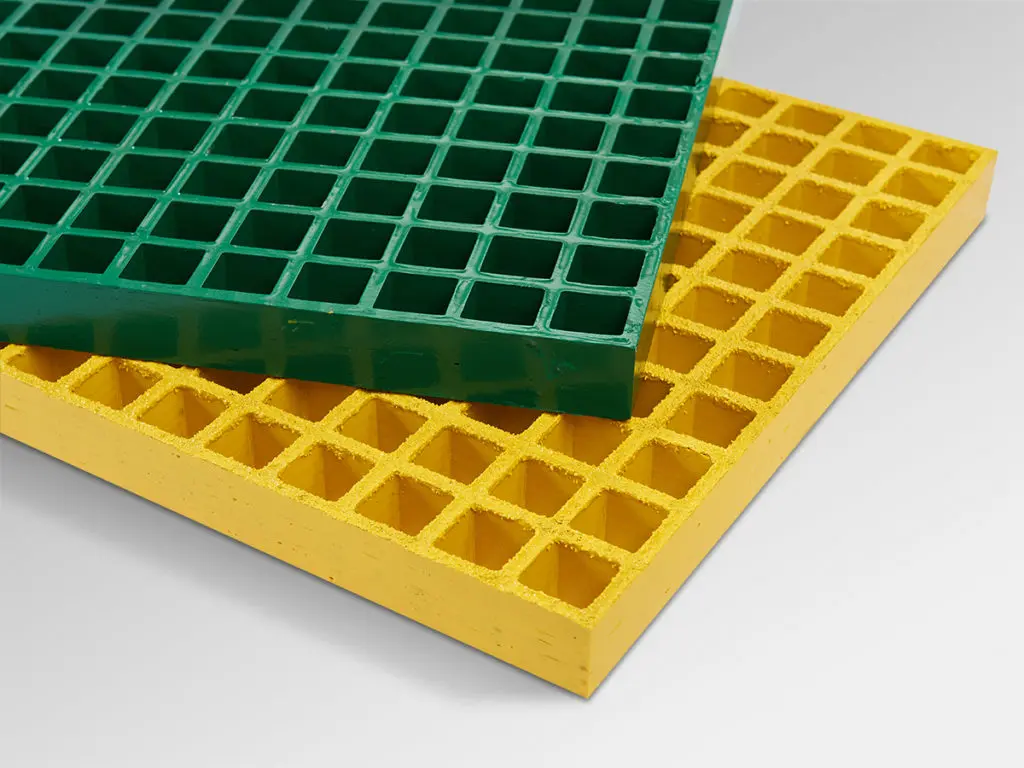

Molded FRP grating is produced by molding fiberglass rovings and resin in a heated mold, forming a one-piece, bi-directional panel. It offers equal strength in both directions, excellent corrosion resistance, and is easy to cut and install.

With over two decades of expertise in FRP manufacturing, Machs delivers high-performance molded FRP grating engineered for critical industrial applications. Produced through precision molding, each panel features uniform resin-to-glass distribution, excellent bidirectional strength, and superior corrosion resistance. Offered in multiple thicknesses, mesh patterns, and colors, our molded gratings provide safe, slip-resistant flooring and reliable long-term performance in chemical plants, wastewater facilities, and other harsh environments.

Product Range

Our Molded FRP Gratings are designed for flooring, trench covers, platforms, and stair treads in corrosive and wet environments. Produced as one-piece panels with equal strength in both directions, they offer excellent corrosion resistance, slip resistance, and easy on-site cutting. Available in various thicknesses, mesh patterns, and colors to meet diverse industrial needs.

Fire Rating FRP Grating

FRP GratingHeavy Duty FRP Grating

FRP GratingGRP Mini Mesh Grating

FRP GratingFRP Micro Mesh Grating

FRP GratingMolded FRP Grating Isophthalic Resin

FRP Grating38mm GRP Grating

FRP Grating25mm GRP Grating

FRP GratingFRP Mesh Grating

FRP GratingMolded Fiberglass Grating

FRP GratingFRP Mini Mesh

FRP GratingMoulded Fibreglass Grating

FRP GratingFiberglass Grid Grating

FRP GratingHeavy Duty Fiberglass Grating

FRP GratingFRP Mesh Panels

FRP Grating1 1/2″ Deep×1″×6″ SuperSpan

FRP Grating30mm Deep×20mm Mini Mesh

FRP Grating1 1/2″ Deep×1 1/2″ Square Mesh

FRP Grating1 1/4″ Deep×1 1/2″ Square Mesh

FRP Grating1″ Deep×1 1/2″ Square Mesh

FRP Grating1/2″ Deep×2″ Square Mesh

FRP Grating2″ Deep×2″ Square Mesh

FRP Grating1/2″ Deep×1 1/2″ Square Mesh

FRP Grating1 1/2″ Deep×1 1/2″×6″ SuperSpan

FRP Grating1″ Deep×1″×4″ Rectangular Mesh

FRP Grating1 1/2″ Deep×3/4″ Mini Mesh

FRP Grating

Key Features of Molded FRP Grating

Molds are used to create one-piece, bi-directional panels with consistent resin-to-glass ratio, giving molded FRP grating equal strength in both directions and excellent load distribution. It is highly corrosion-resistant, making it ideal for chemical plants, wastewater facilities, and marine environments. Molded grating is easy to cut and install on-site, supports multiple mesh sizes and surface types (concave, grit, smooth), and provides slip-resistant safety even in wet or oily conditions.

Applications

Widely used for flooring, trench covers, platforms, stair treads, and ramps in chemical plants, marine facilities, wastewater treatment, food processing, and electroplating workshops.

Customization process

Ready to start customizing your Molded FRP Grating? Here’s our step-by-step customization process.

Requirements

Tell us size, type, color, and quantity.

Design & Quote

We confirm specs and send you a quote.

Production

Gratings are manufactured with strict QC.

Delivery

Secure packaging and fast global shipping.

Molded Grating - FAQS

Q1: When should I choose molded grating instead of pultruded grating?

Choose molded grating when you need equal strength in both directions, frequent cutouts, or a lightweight solution for flooring, trench covers, or platforms. Pultruded grating is better for long spans and higher loads.

Q2: What mesh sizes and thicknesses are available?

Molded grating is available in a variety of mesh patterns (square, rectangular, mini mesh) and thicknesses ranging from 25mm to 38mm, with custom sizes available upon request.

Q3: Is molded grating slip-resistant?

Yes. Molded grating can be produced with concave or grit surfaces, providing excellent slip resistance even in wet or oily environments.

Q4: How is molded grating installed?

It can be easily cut on-site with standard carbide tools and secured using stainless steel clips or fasteners. This makes installation quick and cost-effective.