Water Infrastructure

- Home

- Application

- Water Infrastructure

Industry Challenges in Water Infrastructure

Water infrastructure systems—including treatment plants, pipelines, pumping stations, and storage facilities—operate in highly corrosive and demanding environments. Constant exposure to moisture, chemicals, and varying temperatures accelerates the deterioration of traditional materials such as steel and concrete, leading to leaks, contamination risks, and costly repairs.

Additionally, many water facilities are located in remote or hard-to-access areas, making maintenance work both labor-intensive and expensive. Safety is also a major concern, as slippery surfaces, high-pressure systems, and electrical hazards increase operational risks. For municipalities, utilities, and contractors, the challenge lies in selecting materials that deliver long-term durability, minimal maintenance, and compliance with stringent health and safety regulations.

Why Most Water Infrastructure Projects Choose FRP

Superior Performance in Corrosive Environments

FRP resists damage from constant exposure to water, chlorine, and other treatment chemicals, making it ideal for wastewater plants and desalination facilities.

Extended Service Life in Harsh Outdoor Conditions

UV-stable and weather-resistant FRP maintains structural integrity in open-air tanks, channels, and coastal installations.

Optimized for Safety in Wet Operations

Anti-slip FRP gratings and non-conductive structures reduce the risk of accidents in treatment plants, pumping stations, and spillways.

Lightweight Yet Structurally Strong

FRP platforms, ladders, and covers are easy to install even in elevated or confined water infrastructure sites, without compromising load capacity.

We provide a comprehensive supply of FRP Water Infrastructure materials

Delivering durable, corrosion-resistant FRP solutions for water treatment plants, pipelines, pumping stations, and other critical water infrastructure projects.

Assisting clients in selecting the right FRP profiles, gratings, and components for specific water infrastructure projects.

Producing FRP products in required dimensions, surface types, and performance grades to meet project specifications.

Ensuring all materials meet relevant industry standards for corrosion resistance, load capacity, and safety.

Secure, on-time shipment of FRP materials to project sites worldwide.

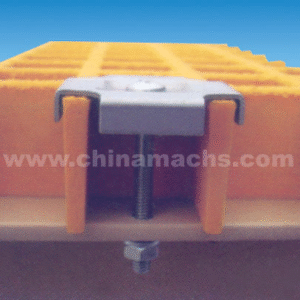

C Clips

Grating ClipsM Clips

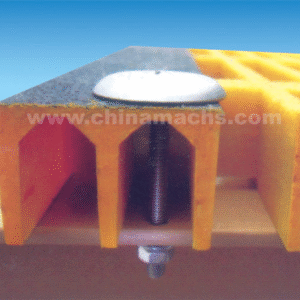

Grating ClipsPAW Clips

Grating ClipsW Clips

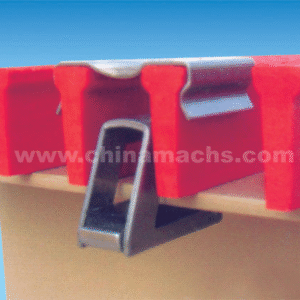

Grating ClipsT Clips

Grating ClipsCSSM Clips – Plan A

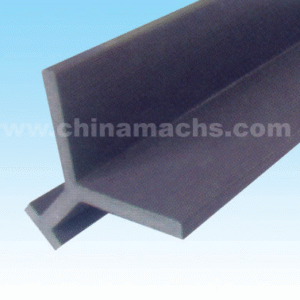

Grating ClipsEmbedment Angle

FRP StructuresAngle

FRP StructuresChannel

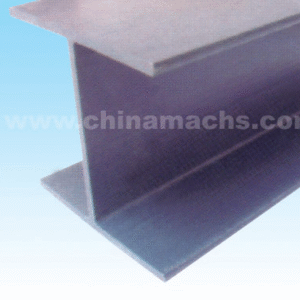

FRP StructuresWide Flange Beam

FRP StructuresSquare Tube

FRP StructuresRound Tube

FRP StructuresFRP Mesh Panels

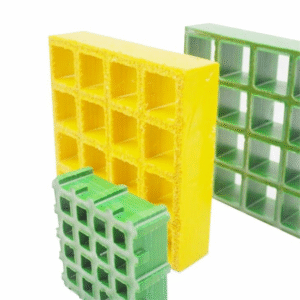

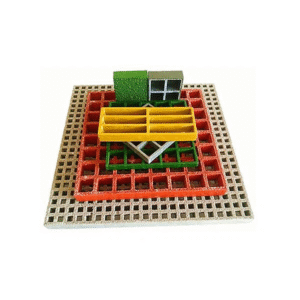

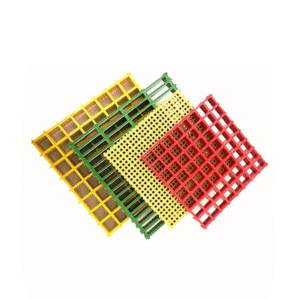

FRP GratingHeavy Duty Fiberglass Grating

FRP GratingFiberglass Grid Grating

FRP GratingMoulded Fibreglass Grating

FRP GratingFRP Mini Mesh

FRP GratingMolded Fiberglass Grating

FRP GratingFRP Mesh Grating

FRP Grating25mm GRP Grating

FRP Grating