G Clips For FRP Grating

- Customizable Options – Tailored size, resin type, and surface finish to meet your project needs.

- Factory-Direct Pricing – Save costs with direct production from our source factory.

- Free Sample Design – Get a sample or design validation before bulk production.

- Global Quality Supply – Reliable quality and on-time delivery worldwide.

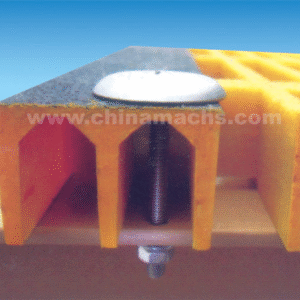

Clip G for grating is used to install fiberglass grating and fiberglass platforms. There are many types of clips: clip M, clip G, clip C, clip L, clip Paw, clip W, clip T, clip CSSM, etc. For a particular application, different clips are needed. If you do not know which clipts to choose, please consult our technical staff. Normal clip material is 316/304 stainless steel.

Specification:

Material: Ss316 / Ss304 / Galvanized

Application: clip for grating

Brand: Machs or according to your requirement

Packing: paper box

Payment: L / C, T / T

Original: Nantong China

Installation Reference

Cutting and machining

Used tools:

Arc Cutting Machine, Angle Grinder, Hand Drill

Security protection

Before cutting, workers should wear protective goggles and masks in order to prevent consumables from getting into the eyes and reduce dust from entering the respiratory tract. You must wear gloves and clothing to prevent dust from getting on the surface of the skin to prevent the occurrence of allergic reactions. Choose a well ventilated and well lit place for cutting. All power tools must be inspected whether damage or not to ensure safety before cutting.

Size check

The cutting tolerance range is typically ± 5 due to factors such as the width of the tool and the knife opposite the grate wall.

Butt processing

The end of the lattice after cutting must be coated with a resin that has a better quality than the resin used on the lattice itself, in order to prevent corrosion from corrosive substances inside the glass fibers.

Q1: How do you ensure the quality of FRP products?

A: All products are manufactured in our own factory under strict ISO-based quality control. We perform raw material testing, process monitoring, and final inspection to ensure every panel meets strength, durability, and corrosion-resistance requirements.

Q2: Where can FRP products be used?

FRP products are ideal for chemical plants, wastewater facilities, offshore platforms, walkways, platforms, stairs, and other areas that require corrosion resistance, lightweight structure, and long service life.

Q3: Do you provide after-sales support?

Yes. We provide clear documentation, installation guidelines (if needed), and technical support. If any quality issue is confirmed after delivery, we offer replacement, rework, or other agreed solutions.

Q4: Can you help with project-specific requirements?

Absolutely. Our team can suggest the right resin system, grating type, and surface finish for your application, and provide drawings or design assistance to ensure project success.