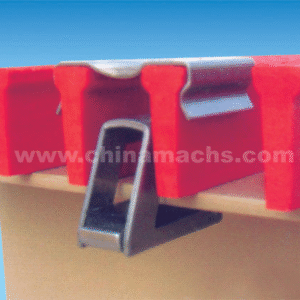

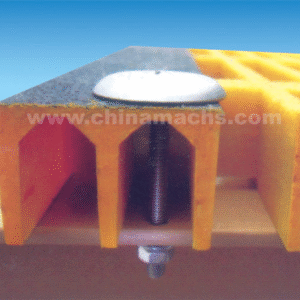

Fiberglass Grating Fasteners

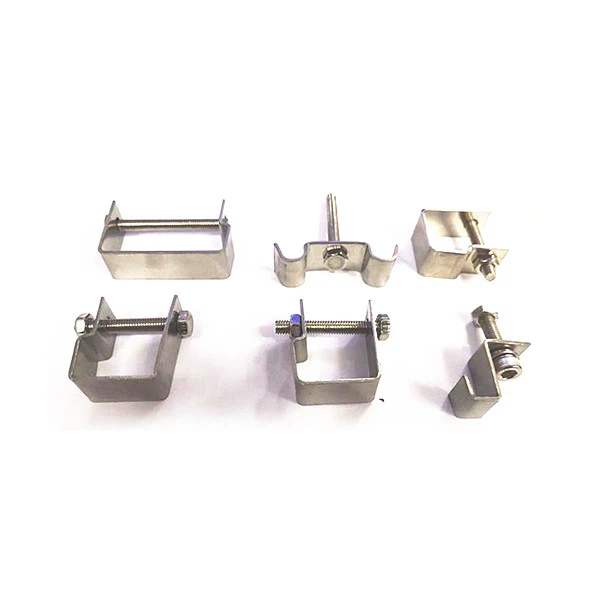

Fiberglass grating fasteners are used as special connectors for FRP gratings, made of 304 stainless steel, which is corrosion-resistant and high-strength.

- Customizable Options – Tailored size, resin type, and surface finish to meet your project needs.

- Factory-Direct Pricing – Save costs with direct production from our source factory.

- Free Sample Design – Get a sample or design validation before bulk production.

- Global Quality Supply – Reliable quality and on-time delivery worldwide.

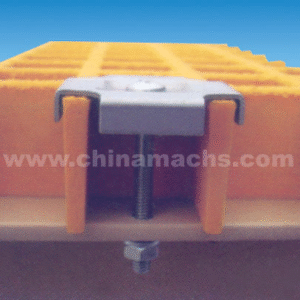

The tree grate is a cover plate installed in the tree pit with various spaces to allow water to pass through. It is mainly used to protect trees, but also to facilitate the passage of water for irrigation. The commonly used tree grate is mainly made of fiberglass. Fiberglass grating fasteners are needed for fixing the fiberglass tree grate, so that not only can fix the tree grate but also protect the tree.

Fiberglass grating fasteners are divided into M-type, R-type, C-type, L-type, W-type, and G-type. They are made of high-quality 304 stainless steel, with corrosion resistance, high strength and fatigue resistance. They have a longer service life than ordinary 201 stainless steel .

| |

| Material | stainless steel 304 |

| Style | M-type, R-type, C-type, L-type, W-type, and G-type |

| Applicable grating | Customized according to grating size, type and application |

| Custom style | Accept (according to applications, CAD drawings, size information) |

| Custom size | Accept |

Q1: How do you ensure the quality of FRP products?

A: All products are manufactured in our own factory under strict ISO-based quality control. We perform raw material testing, process monitoring, and final inspection to ensure every panel meets strength, durability, and corrosion-resistance requirements.

Q2: Where can FRP products be used?

FRP products are ideal for chemical plants, wastewater facilities, offshore platforms, walkways, platforms, stairs, and other areas that require corrosion resistance, lightweight structure, and long service life.

Q3: Do you provide after-sales support?

Yes. We provide clear documentation, installation guidelines (if needed), and technical support. If any quality issue is confirmed after delivery, we offer replacement, rework, or other agreed solutions.

Q4: Can you help with project-specific requirements?

Absolutely. Our team can suggest the right resin system, grating type, and surface finish for your application, and provide drawings or design assistance to ensure project success.