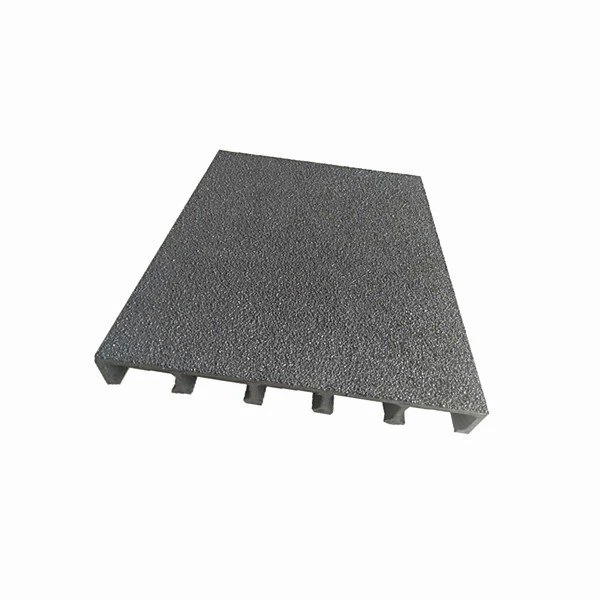

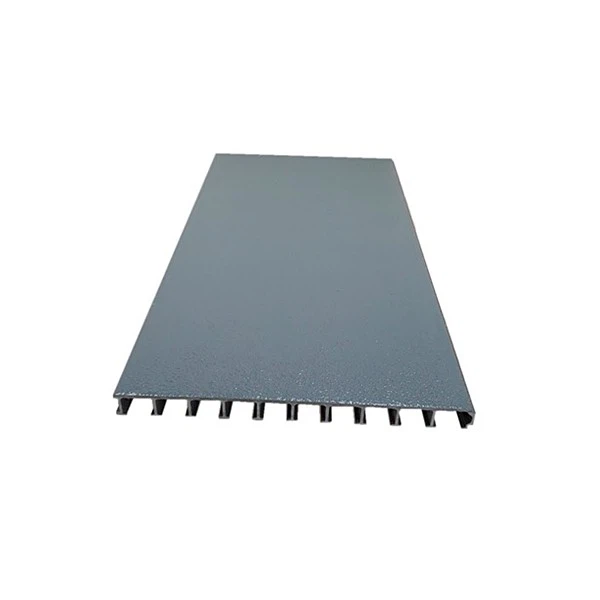

Fiberglass Dock Decking

Fiberglass dock decking is a monolithic panel with uniform cross-section formed at one time by pultrusion process. This kind of deck panel is corrosion resistant, and has a closed surface with non-slip grit.

Accept Customized Sizes

A Choice of RAL Colors Available

- Customizable Options – Tailored size, resin type, and surface finish to meet your project needs.

- Factory-Direct Pricing – Save costs with direct production from our source factory.

- Free Sample Design – Get a sample or design validation before bulk production.

- Global Quality Supply – Reliable quality and on-time delivery worldwide.

When steel plate is used as the dock decking, in order to improve its corrosion resistance, primer coating and metal spraying are generally carried out on the surface of the plate, and regular inspections and repairs are required. To a certain extent, it increases the cost. Therefore, the original steel deck is replaced by the fiberglass deck, which utilizes the corrosion resistance of the fiberglass deck and greatly improves its service life.

Fiberglass dock decking maintains most of the characteristics of fiberglass pultruded grating covers, but there are also significant differences. Fiberglass dock decking is formed at one time and have good integrity, eliminating the secondary bonding between the pultruded grating and the closed cover panel. It makes fiberglass dock decking more resistant to impact, and long-term use will not cause the delamination and falling off like fiberglass pultruded grating covers.

When vinyl is recommended as the base material to produce the fiberglass dock decking, it has excellent corrosion resistance.

◆ Common size of Mach’s fiberglass dock decking

▽ Mach’s standard fiberglass deck

Unit: mm

| Model No. | Size A B T | Weight |

| DP305 | 305×47.5×6.4 | 8.65kg/m |

● Custom fabricated sizes also available upon your request.

▽ Interconnected by “J” interlocking panels

Unit: mm

| Model | Size A B t1 t2 | Weight |

| DPJ500 | 500×40×4×4 | 8.40kg/m |

Q1: How do you ensure the quality of FRP products?

A: All products are manufactured in our own factory under strict ISO-based quality control. We perform raw material testing, process monitoring, and final inspection to ensure every panel meets strength, durability, and corrosion-resistance requirements.

Q2: Where can FRP products be used?

FRP products are ideal for chemical plants, wastewater facilities, offshore platforms, walkways, platforms, stairs, and other areas that require corrosion resistance, lightweight structure, and long service life.

Q3: Do you provide after-sales support?

Yes. We provide clear documentation, installation guidelines (if needed), and technical support. If any quality issue is confirmed after delivery, we offer replacement, rework, or other agreed solutions.

Q4: Can you help with project-specific requirements?

Absolutely. Our team can suggest the right resin system, grating type, and surface finish for your application, and provide drawings or design assistance to ensure project success.

Related Products

相关产品

FRP Deck Panels

FRP Decking