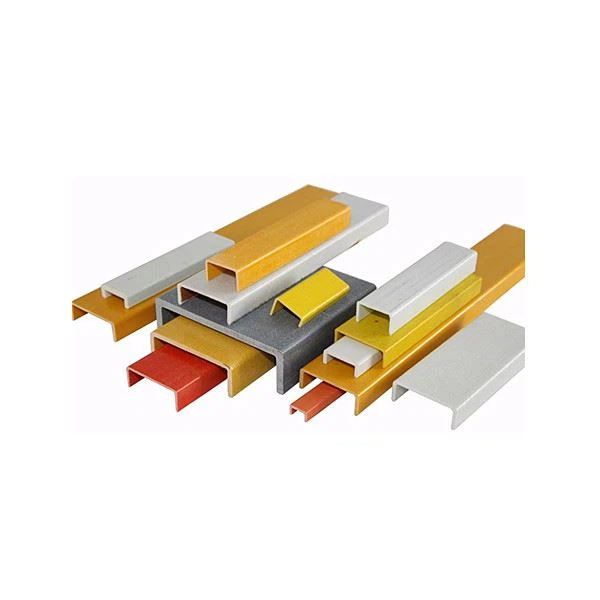

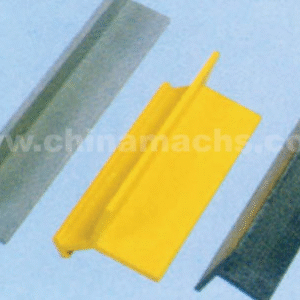

FRP C Channel

FRP c channel is corrosion resistant enough to resist the damage caused by the atmosphere, water and general concentrations of acids, alkalis, salts, and various oils and solvents. It can be applied to all aspects of industrial building materials, and is replacing carbon steel, stainless steel, wood, non-ferrous metals, etc.

- Customizable Options – Tailored size, resin type, and surface finish to meet your project needs.

- Factory-Direct Pricing – Save costs with direct production from our source factory.

- Free Sample Design – Get a sample or design validation before bulk production.

- Global Quality Supply – Reliable quality and on-time delivery worldwide.

If you have visited the coastal buildings, smelters, chemical workshops, seafood farming and other industrial buildings in corrosive environments, you will never forget the sight of the coated colored steel channels being corroded beyond sight. FRP c channel is recommended in response to the requirements of corrosive environments.

When it comes to the application of FRP c channel, it is quite common and widespread. For example, the cable channel can also be made of FRP c channel. It is not only used in power cables, but also in some chemical and petroleum industries, and even in FRP stairs.

◆ Applications of FRP c channel

1.Electric industry: cable channel, cable ladder brackets, motor slot wedge, etc.

2.Building and civil engineering materials: building support columns, bridge components.

3.Land transportation: refrigerated truck components, truck structural parts.

4.Corrosion-resistant equipment: operating platform bracket, water treatment equipment, corrosion resistant storage tank protection frame, cooling tower bracket.

◆ Common size of Mach’s FRP c channel

| Model No. | Size A×B×C | Weight (kg/m) |

| C50 | 50×14×3.2 | 0.44 |

| C76A | 76×22×6.4 | 1.31 |

| C76B | 76×25×4.8 | 1.06 |

| C76C | 76×38×6.4 | 1.70 |

| C102A | 102×27×3.2 | 0.91 |

| C102B | 102×29×6.4 | 1.37 |

| C102C | 102×29×6.4 | 1.78 |

| C102D | 102×35×4.8 | 1.48 |

| C102E | 102×44×4.8 | 1.65 |

| C120 | 102×50×5.0 | 2.00 |

| C150 | 150×41×8.0 | 3.28 |

| C152A | 152×42×6.4 | 2.72 |

| C152B | 152×42×8.0 | 3.35 |

| C152C | 152×42×9.5 | 3.95 |

| C152D | 152×50×8.0 | 3.59 |

| C203A | 203×56×6.4 | 3.68 |

| C203B | 203×56×9.5 | 5.34 |

| C254 | 254×70×12.7 | 8.90 |

| C210A | 210×55×5.0 | 2.95 |

| C210B | 210×80×5.0 | 3.42 |

| C210C | 210×85×5.0 | 3.52 |

| C120A | 120×25×5.0 | 1.52 |

| C120B | 120×30×5.0 | 1.62 |

| C120C | 120×40×5.0 | 1.81 |

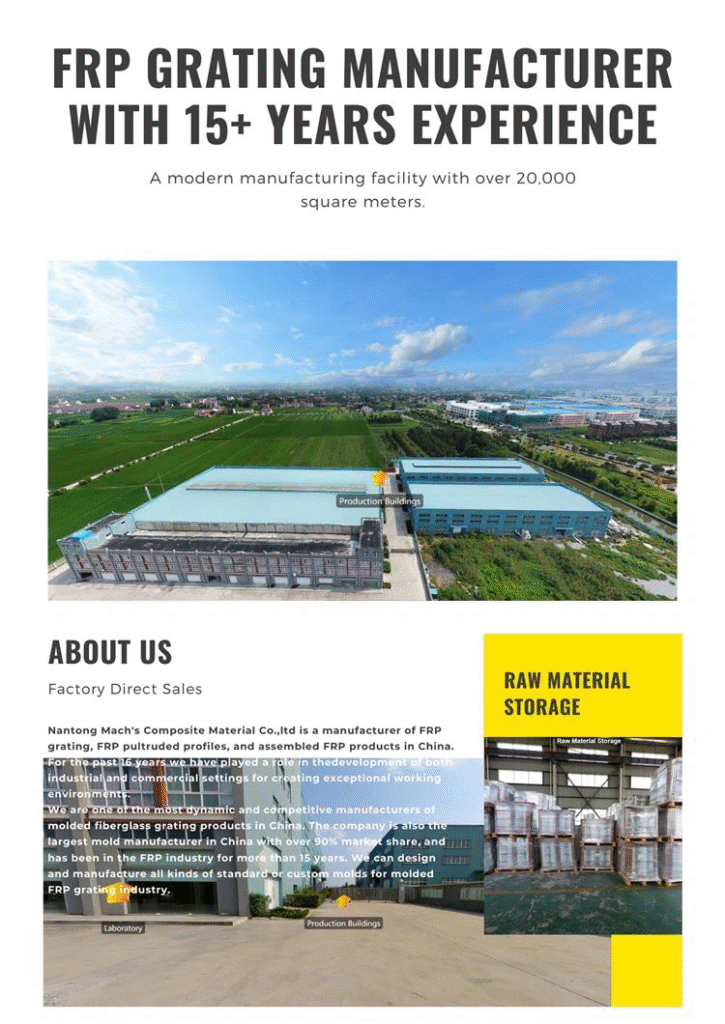

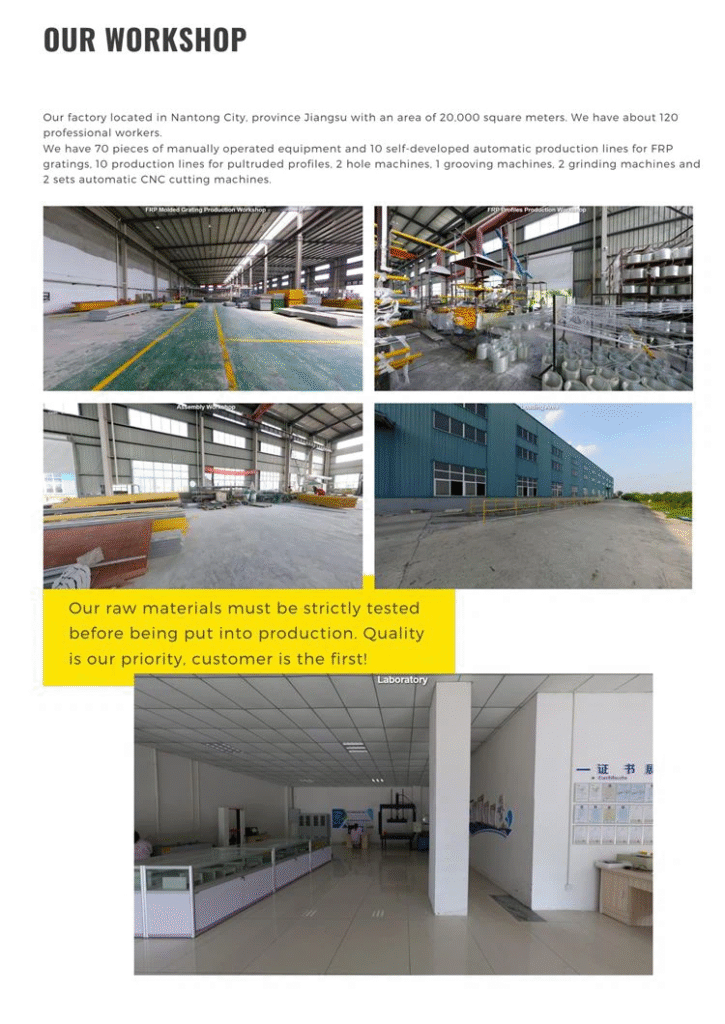

Q1: How do you ensure the quality of FRP products?

A: All products are manufactured in our own factory under strict ISO-based quality control. We perform raw material testing, process monitoring, and final inspection to ensure every panel meets strength, durability, and corrosion-resistance requirements.

Q2: Where can FRP products be used?

FRP products are ideal for chemical plants, wastewater facilities, offshore platforms, walkways, platforms, stairs, and other areas that require corrosion resistance, lightweight structure, and long service life.

Q3: Do you provide after-sales support?

Yes. We provide clear documentation, installation guidelines (if needed), and technical support. If any quality issue is confirmed after delivery, we offer replacement, rework, or other agreed solutions.

Q4: Can you help with project-specific requirements?

Absolutely. Our team can suggest the right resin system, grating type, and surface finish for your application, and provide drawings or design assistance to ensure project success.

Related Products

相关产品

Square Fiberglass Rod

FRP ProfilesY steel、T steel

FRP ProfilesFRP Round Tube

FRP ProfilesFiberglass Angle Shapes

FRP ProfilesSolid party great、Solid round rods

FRP ProfilesFiberglass Round Bar

FRP ProfilesFRP Square Tube

FRP ProfilesFiberglass C Channel

FRP Profiles