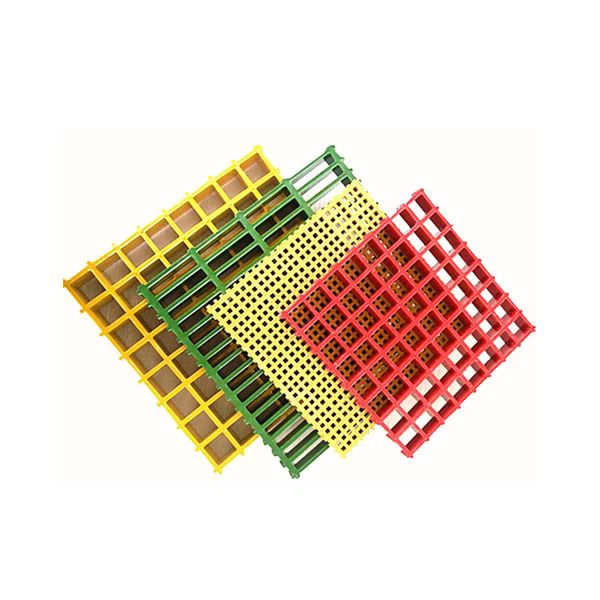

FRP Mesh Grating

FRP mesh grating can greatly improve its load-bearing capacity inasmuch as the mesh design.

Accept Customized Sizes of FRP Mesh Grating

A Choice of RAL Colors Available

- Customizable Options – Tailored size, resin type, and surface finish to meet your project needs.

- Factory-Direct Pricing – Save costs with direct production from our source factory.

- Free Sample Design – Get a sample or design validation before bulk production.

- Global Quality Supply – Reliable quality and on-time delivery worldwide.

One of the outstanding features of FRP mesh grating is to save material. In addition, in terms of stability, the mesh-shaped grating can greatly improve its own load-bearing capacity and is not easy to bend. In terms of flame-retardant insulation, there will be no sparks caused by collision during installation and use of FRP mesh grating, and it is suitable for use in flammable and explosive environments.

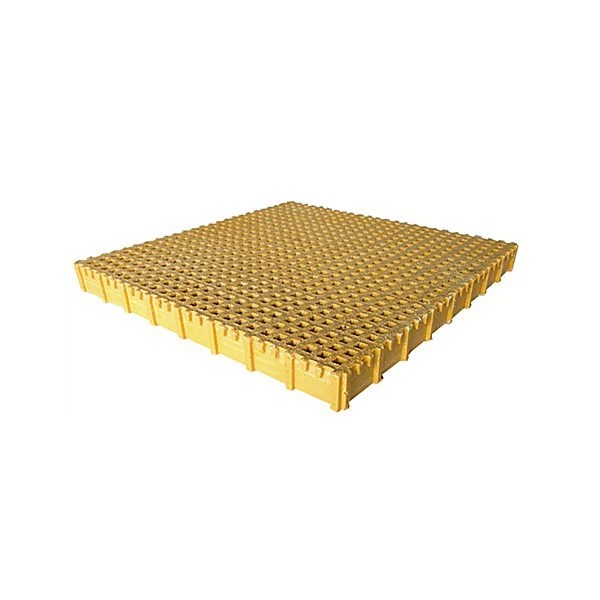

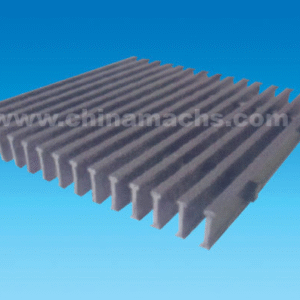

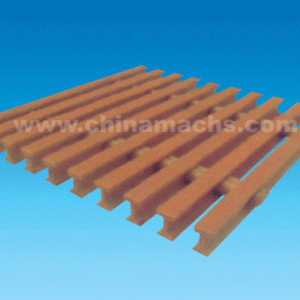

There are three surface types of FRP mesh grating, which can be used in different environments:

▽ Concave surface

Concave surface FRP mesh grating is universal. In the production of FRP mesh grating, it needs to be molded so that grooves appear on the surface. It is only applicable to artificial walkways for the reason that its own concave surface has general slip resistance and wear resistance.

▽ Grit surface

Grit surface FRP mesh grating is made by adding quartz sand to the surface of the grating, which is used in places with high protection requirements, especially in humid, oily or frozen environments, such as bridge decks, floors, trench boards, car washes, etc. .

▽ Smooth surface

It makes the surface of the FRP mesh grating smooth on the basis of the original concave surface. Smooth surface FRP mesh grating is non-slip, mainly used in building decoration.

◆ Common size of FRP mesh grating

▽ Square mesh FRP mesh grating

Unit: mm

| Grating Thickness | Mesh Size | Load Bar Width(top/bottom) | Open Area | Weight |

| 13 | 38×38 | 6.0/5.0 | 78% | 6.00kg/m2 |

| 15 | 38×38 | 6.0/5.0 | 78% | 7.00kg/m2 |

| 20 | 38×38 | 6.0/5.0 | 65% | 9.80kg/m2 |

| 25 | 38×38 | 6.4/5.0 | 68% | 12.30kg/m2 |

| 30 | 38×38 | 6.5/5.0 | 68% | 14.60kg/m2 |

| 38 | 38×38 | 7.0/5.0 | 68% | 19.50kg/m2 |

| 30 | 38×38 | 10.5/9.0 | 58% | 25.00kg/m2 |

| 35 | 38×38 | 10.5/9.0 | 56% | 29.40kg/m2 |

| 50 | 38×38 | 11.0/9.0 | 56% | 42.00kg/m2 |

| 60 | 38×38 | 11.5/9.0 | 54% | 50.40kg/m2 |

| 25 | 40×40 | 7.0/5.0 | 67% | 12.30kg/m2 |

| 30 | 40×40 | 7.0/5.0 | 67% | 14.60kg/m2 |

| 40 | 40×40 | 7.0/5.0 | 67% | 19.20kg/m2 |

| 13 | 50×50 | 6.0/5.0 | 82% | 4.80kg/m2 |

| 13 | 50.8×50.8 | 7.0/6.0 | 82% | 5.80kg/m2 |

| 40 | 50×50 | 6.8/5.0 | 80% | 15.82kg/m2 |

| 25 | 50×50 | 7.5/6.0 | 78% | 11.50kg/m2 |

| 50 | 50×50 | 7.0/5.0 | 78% | 20.80kg/m2 |

| 50 | 50×50 | 8.0/6.0 | 78% | 23.70kg/m2 |

| 63 | 50×50 | 8.3/6.0 | 78% | 28.80kg/m2 |

| 23 | 79×79 | 6.5/5.0 | 80% | 5.70kg/m2 |

| 25 | 83×83 | 7.0/5.0 | 84% | 5.80kg/m2 |

| 40 | 83×83 | 7.0/5.0 | 84% | 9.50kg/m2 |

| 30 | 12.7×12.7/38×38 | 7.5&4.5/6.0 | 30% | 22.00kg/m2 |

| 25 | 19×19/38×38 | 6.5/5.0 | 40% | 16.80kg/m2 |

| 38 | 19×19/38×38 | 7.0/5.0 | 40% | 23.50kg/m2 |

| 14 | 20×20/40×40 | 7.0/5.0 | 42% | 10.50kg/m2 |

| 30 | 20×20/40×40 | 7.0/5.0 | 42% | 18.00kg/m2 |

| 40 | 20×20/40×40 | 7.0/5.0 | 42% | 23.70kg/m2 |

| 50 | 25×25/50×50 | 8.0/6.0 | 55% | 28.50kg/m2 |

| 38 | 26×26/52×52 | 6.0/5.0 | 60% | 19.50kg/m2 |

▽ Rectangular mesh FRP mesh grating

Unit: mm

| Grating Thickness | Mesh Size | Load Bar Width(top/bottom) | Open Area | Weight |

| 38 | 25×50 | 11.0/9.0 | 48% | 30.30kg/m2 |

| 50 | 25×50 | 12.0/9.0 | 48% | 41.00kg/m2 |

| 25 | 25×100 | 7.0/5.5 | 67% | 13.00kg/m2 |

| 25 | 25×100 | 6.5/5.0 | 67% | 13.83kg/m2 |

| 25 | 25×100 | 9.5/8.0 | 52% | 19.50kg/m2 |

| 30 | 25×100 | 7.0/5.5 | 67% | 15.60kg/m2 |

| 38 | 25×100 | 8.0/6.0 | 52% | 22.50kg/m2 |

| 38 | 38×100 | 8.0/6.0 | 65% | 16.40kg/m2 |

| 38 | 25×152 | 9.0/6.5 | 63% | 22.50kg/m2 |

| 38 | 38×152 | 8.0/6.0 | 67% | 15.92kg/m2 |

| 40 | 60×220 | 6.3/5.0 | 67% | 8.80kg/m2 |

| 38 | 25×100 | 15.0/5.0 | 62% | 21.00kg/m2 |

| 38 | 38×152 | 15.0/8.0 | 62% | 18.60kg/m2 |

| 50 | 38×100 | 8.0/5.0 | 62% | 15.30kg/m2 |

Q1: How do you ensure the quality of FRP products?

A: All products are manufactured in our own factory under strict ISO-based quality control. We perform raw material testing, process monitoring, and final inspection to ensure every panel meets strength, durability, and corrosion-resistance requirements.

Q2: Where can FRP products be used?

FRP products are ideal for chemical plants, wastewater facilities, offshore platforms, walkways, platforms, stairs, and other areas that require corrosion resistance, lightweight structure, and long service life.

Q3: Do you provide after-sales support?

Yes. We provide clear documentation, installation guidelines (if needed), and technical support. If any quality issue is confirmed after delivery, we offer replacement, rework, or other agreed solutions.

Q4: Can you help with project-specific requirements?

Absolutely. Our team can suggest the right resin system, grating type, and surface finish for your application, and provide drawings or design assistance to ensure project success.

Related Products

相关产品

T-Bar 1 1/2″Deep 40%Open(I15-40)

FRP GratingT-Bar 1″Deep 60%Open(T10-60 ADA)

FRP GratingT-Bar 1″Deep 50%Open(T10-50)

FRP Grating1/2″ Deep×1 1/2″ Square Mesh

FRP GratingT-Bar 1 1/2″Deep 60%Open(IP15-60 ADA)

FRP GratingT-Bar 1″Deep 50%Open(T10-50)

FRP Grating1 1/2″ Deep×3/4″ Mini Mesh

FRP GratingT-Bar 1 1/2″Deep 33%Open(T15-33)

FRP Grating