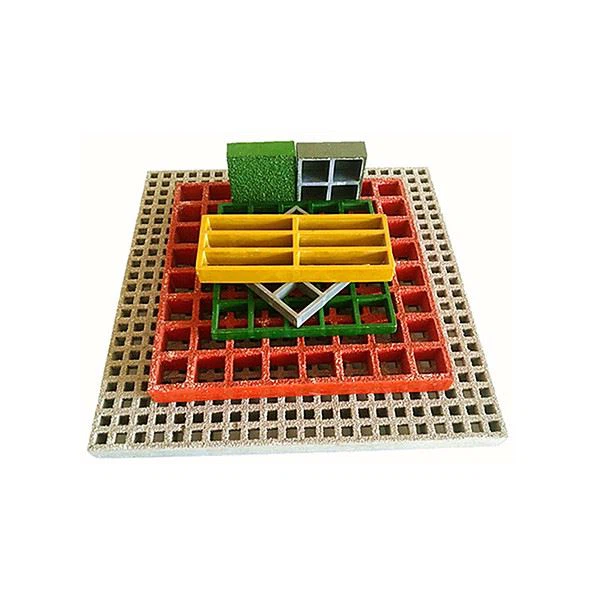

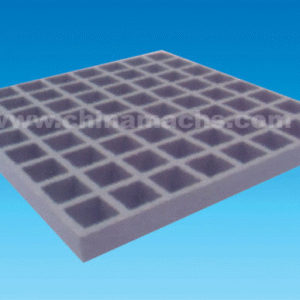

Molded Fiberglass Grating

Molded fiberglass grating has the same hardness and bearing capacity as metal grating, but its weight is only one-fourth of steel and two-thirds of aluminum.

Accept Customized Sizes

A Choice of RAL Colors Available

- Customizable Options – Tailored size, resin type, and surface finish to meet your project needs.

- Factory-Direct Pricing – Save costs with direct production from our source factory.

- Free Sample Design – Get a sample or design validation before bulk production.

- Global Quality Supply – Reliable quality and on-time delivery worldwide.

As a new type of composite plate, molded fiberglass grating possesses outstanding advantages and characteristics. Its excellent corrosion resistance is the main reason for its superiority over the metal grating. The metal grating has poor durability. It is easy to deform once subjected to excessive external pressure, and it is difficult to restore the original shape.

Also, due to the integrally cast construction, molded fiberglass grating offers a bi-directional span capability that affords usage in even more applications than traditional unidirectional grating products.

There are two types of molded fiberglass grating non-slip surface: naturally formed concave surface and grit surface, which provide superior slip resistance, and the grit layer is not easy to peel off and is durable.

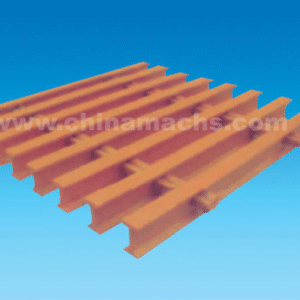

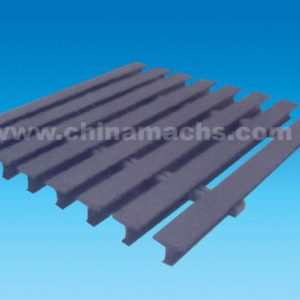

◆ Differences between molded fiberglass grating and pultruded fiberglass grating

▽ Different molding process:

Molded fiberglass grating is made with large metal molds combined with manual winding and resin pouring process.

Pultruded fiberglass grating is made of untwisted glass fiber roving, glass fiber mat and other reinforcing materials under the pultrusion molding machine, which are impregnated with resin through a resin bath, and then heated and shaped by a forming mold.

▽ Different carrying capacity:

Pultruded fiberglass grating has a high glass fiber content (65%-70%) in the direction of the load-bearing bar. Therefore, compared with the molded fiberglass grating, it is more advantageous when used in a large span.

▽ Different price

Relatively speaking, pultruded fiberglass grating is more expensive than molded fiberglass grating in view of the fact that the production process of pultruded fiberglass grating is more complicated.

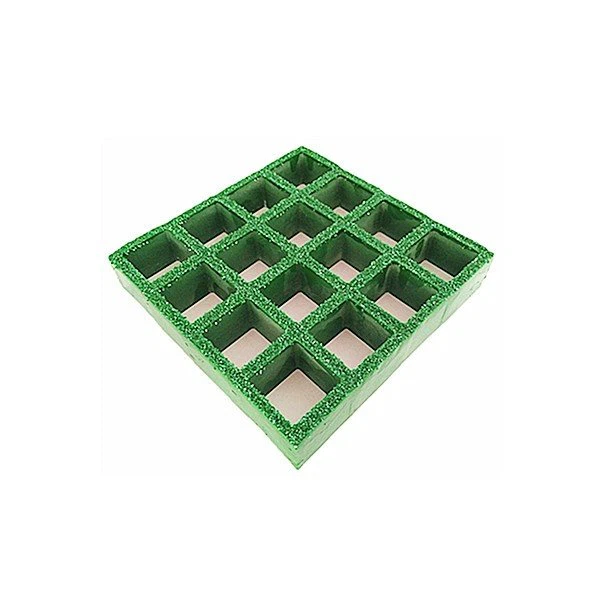

▽ Square mesh molded fiberglass grating

Unit: mm

|

| |

| Raw Materials | Resin, glass fiber roving, aluminum hydroxide |

| Available Colors | A Choice of RAL Colors Available |

| Grating Thickness | 13, 20, 23, 25, 30, 38, 40, 50, 63 |

| Mesh Size | 38×38, 40×40, 50×50, 50.8×50.8, 79×79, 83×83 |

| Available Panel Size | 405×3569, 915×3050, 1007×3007, 1007×4007, 1007× 4047, 1906×4012, 1220×4000, 1220×3660, 1225×3660,1220×2440, 1225×2440, 1220×4000, 1225×4000,1218×4100, 1247×4047, 1225×5035, 1524×4000, 1788×4531 |

| Key Feature | Rich resin and color option Excellent corrosion resistance Bi-Directional strength |

| Typical Application | Flooring, trench covers, stair treads, walkways, working platforms, screening, drains |

▽ Mini mesh molded fiberglass grating

Unit: mm

| |

| Raw Materials | Resin, glass fiber roving, aluminum hydroxide |

| Available Colors | A Choice of RAL Colors Available |

| Grating Thickness | 14, 25, 30, 38, 40, 50 |

| Mesh Size | 12.7×12.7/38×38, 19×19/38×38, 20×20/40×40, 25×25/50×50, 26×26/52×52 |

| Available Panel Size | 1220×3660, 1220×2440, 1220×4000, 1524×4000, 915×3050, 1247×4047, 1007×3007, 1007×4047 |

| Key Feature | Non-Slip Corrosion Resistant ADA Compliant |

| Typical Application | Stairs, walkways, containment area flooring |

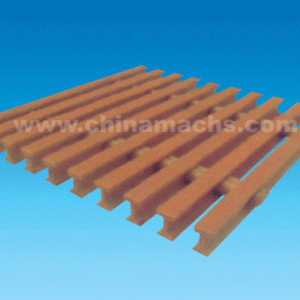

▽ Rectangular mesh molded fiberglass grating

Unit: mm

| |

| Raw Materials | Resin, glass fiber roving, aluminum hydroxide |

| Available Colors | A Choice of RAL Colors Available |

| Grating Thickness | 25, 30, 38, 40 |

| Mesh Size | 25×100, 38×100, 25×152, 38×152, 60×220 |

| Available Panel Size | 1007×3007, 1220×3660, 1220×2440, 915×3050, 1788×2238 |

| Key Feature | Superior strength Long span ability Corrosion resistant Impact resistant |

| Typical Application | Bridges, platforms, trench covers |

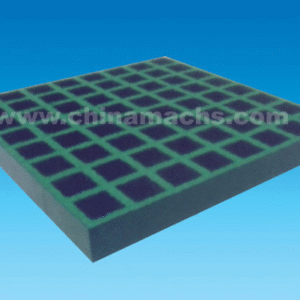

▽ Heavy duty molded fiberglass grating

Unit: mm

| |

| Raw Materials | Resin, glass fiber roving, aluminum hydroxide |

| Available Colors | A Choice of RAL Colors Available |

| Common size(grating thickness×mesh size) | 30×38×38, 35×38×38, 50×38×38, 60×38×38, 38×25×50, 50×25×50, 25×25×100 |

| Available Panel Size | 1220×3660, 1220×2440, 1220×4000, 915×3050, 1247×4047, 1007×4047, 1007×3007 |

| Key Feature | Bi-directional strength Corrosion resistant High load capacity Non-slip Long span ability |

| Typical Application | Drainage channels, loading docks, trenches at overhead doors |

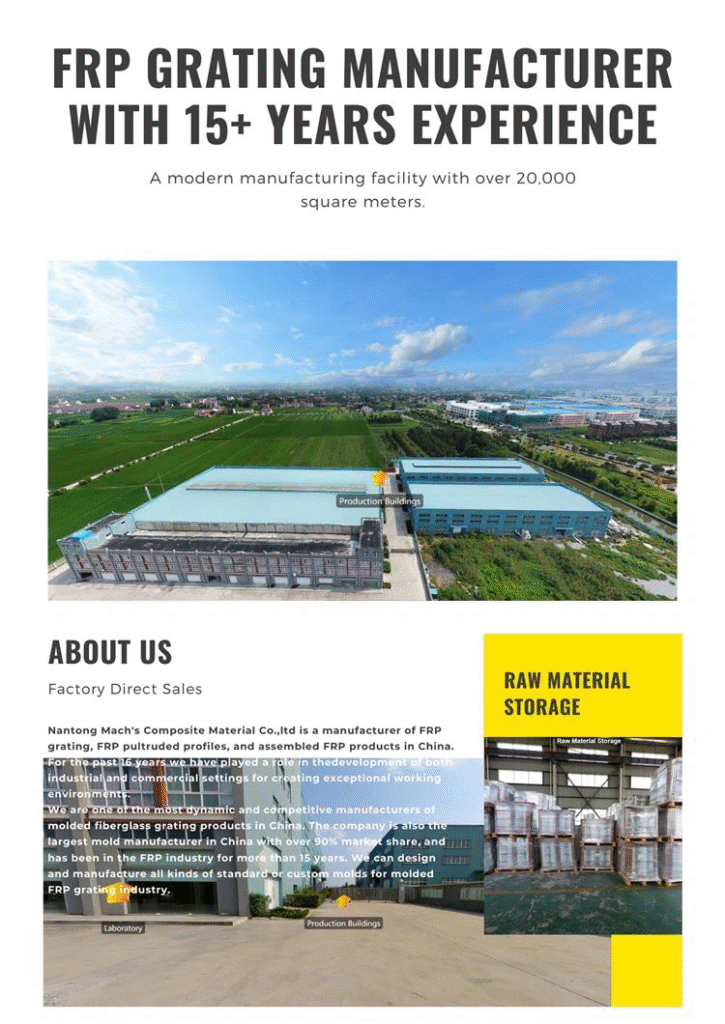

Q1: How do you ensure the quality of FRP products?

A: All products are manufactured in our own factory under strict ISO-based quality control. We perform raw material testing, process monitoring, and final inspection to ensure every panel meets strength, durability, and corrosion-resistance requirements.

Q2: Where can FRP products be used?

FRP products are ideal for chemical plants, wastewater facilities, offshore platforms, walkways, platforms, stairs, and other areas that require corrosion resistance, lightweight structure, and long service life.

Q3: Do you provide after-sales support?

Yes. We provide clear documentation, installation guidelines (if needed), and technical support. If any quality issue is confirmed after delivery, we offer replacement, rework, or other agreed solutions.

Q4: Can you help with project-specific requirements?

Absolutely. Our team can suggest the right resin system, grating type, and surface finish for your application, and provide drawings or design assistance to ensure project success.

Related Products

相关产品

1 1/2″ Deep×1 1/2″ Square Mesh

FRP Grating1″ Deep×1 1/2″ Square Mesh

FRP GratingT-Bar 1″Deep 18%Open(T10-18)

FRP GratingT-Bar 1″Deep 50%Open(T10-50)

FRP Grating1 1/4″ Deep×1 1/2″ Square Mesh

FRP GratingT-Bar 1/4″Deep 40%Open(I12-40)

FRP GratingT-Bar 1″Deep 33%Open(T10-33)

FRP Grating1/2″ Deep×1 1/2″ Square Mesh

FRP Grating