When planning a new water treatment project or upgrading an existing plant, engineers and project managers face a critical decision: which construction materials to choose. Walkways, maintenance platforms, and tank covers are constantly exposed to moisture, chemicals, and heavy use. The wrong choice can lead to frequent replacements, high maintenance costs, and even safety risks. Traditional options such as steel, wood, and concrete have long been used, but Fiber Reinforced Plastic (FRP) grating has emerged as a smarter and more sustainable solution.

The Challenges of Traditional Materials

Steel grating is strong, but in a water treatment environment it corrodes quickly. Even with protective coatings, it requires constant maintenance and regular replacement. Wood absorbs water, swells, and rots, making it unsuitable for industrial applications. Concrete may seem durable, but it is extremely heavy, hard to install, and prone to cracking or deterioration over time.

These limitations have driven many engineers to look for alternatives that are lightweight, corrosion-resistant, and cost-effective in the long run.

Why FRP Grating Works Better

Corrosion Resistance

FRP grating is made from resin and fiberglass, making it highly resistant to acids, alkalis, and other aggressive chemicals found in wastewater plants.

Slip Resistance

With a gritted or serrated surface, FRP grating reduces the risk of slips and falls, keeping workers safe even in wet environments.

Lightweight but Strong

FRP is about 50% lighter than steel, which makes it easier to transport, handle, and install without compromising on load capacity.

Long Service Life

While steel may need to be replaced every 3–5 years in harsh environments, FRP can last 20 years or more with minimal degradation.

Low Maintenance

FRP grating does not require painting or coating and is easy to clean, saving time and money in long-term operations.

Compliance and Certifications

Water treatment projects must meet strict safety and quality standards. Reliable FRP grating manufacturers will provide:

ISO 9001 for quality management

ISO 14001 for environmental management

CE Certification for European projects

ASTM Standards such as ASTM E84 (fire resistance), ASTM D635 (burning behavior), and ASTM D790 (flexural strength)

Third-party reports from SGS, Intertek, or other independent labs

These certifications give engineers confidence that the materials will pass inspections and keep the project compliant.

Cost and Lifetime Value

FRP grating often costs more than steel upfront, but the long-term savings are significant. Steel requires frequent maintenance and early replacement due to corrosion, while FRP continues performing for decades with little upkeep. Over a 10–20 year span, FRP grating lowers the total cost of ownership (TCO) by reducing downtime, replacement cycles, and labor costs.

Real-World Applications

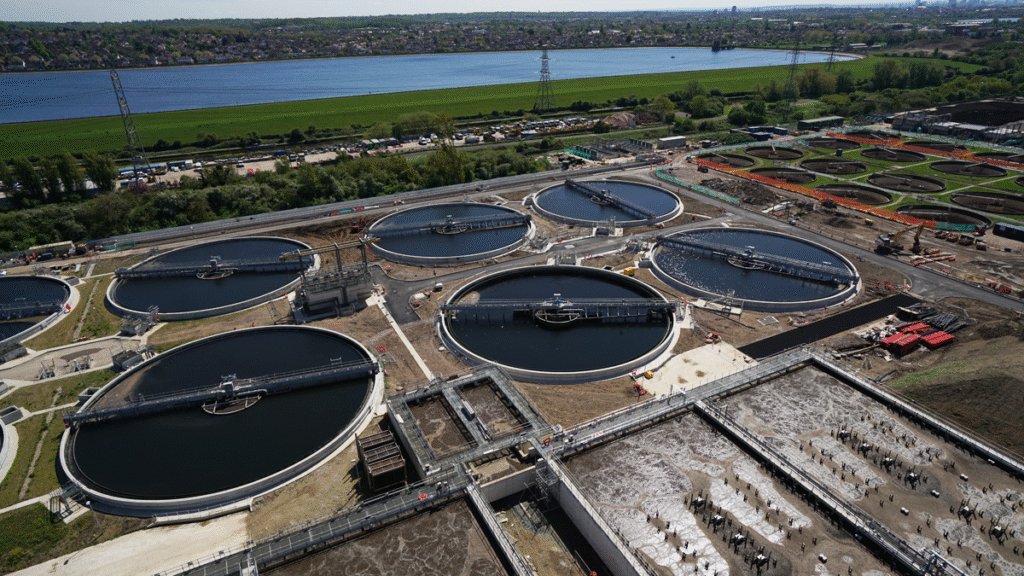

FRP grating is no longer an experimental material—it has been proven in major water treatment projects worldwide:

New York City Wastewater Treatment Plants (USA) – FRP grating used in walkways and aeration tanks to combat corrosion and improve worker safety.

Thames Water Facilities (UK) – Platforms and sedimentation tank covers upgraded with FRP grating, reducing maintenance needs.

Singapore PUB Water Reclamation Plants – FRP grating installed in high-humidity, chemical-rich environments for reliable performance.

Saudi Aramco Wastewater Facilities (Middle East) – Chosen for its corrosion and UV resistance in harsh desert and chemical conditions.

Sydney Water Treatment Plants (Australia) – FRP grating adopted for operator walkways, meeting strict local safety codes.

These projects demonstrate that FRP grating is trusted globally in some of the harshest environments.

Final Thoughts

For engineers and project managers planning water treatment facilities, choosing the right material is about more than upfront cost. Traditional materials struggle in corrosive, wet, and chemical-rich environments, leading to higher maintenance and safety risks. FRP grating solves these problems with its superior corrosion resistance, safety features, long service life, and compliance with international standards.

In the long run, FRP grating is not just the safer choice—it is also the most economical and reliable investment for water treatment plants.