In modern construction, marine, and industrial engineering, the choice of structural materials plays a critical role in durability, performance, and cost-efficiency. While traditional materials like steel, aluminum, and wood still dominate, FRP (Fiber-Reinforced Polymer) Profiles are becoming an increasingly popular alternative.

FRP profiles combine high-strength reinforcement fibers—most commonly fiberglass—with a polymer resin matrix. This combination creates a material that is strong yet lightweight, corrosion-resistant, electrically non-conductive, and capable of being formed into a wide range of structural shapes. Whether for building frameworks, walkways, handrails, or marine infrastructure, FRP profiles deliver consistent performance in challenging environments.

What Are FRP Profiles?

FRP Profiles are pre-formed structural shapes made from continuous strands of fiberglass embedded in a thermoset resin matrix, such as polyester, vinyl ester, or epoxy. The resin binds and protects the fibers, while the fibers provide tensile and flexural strength.

These profiles are typically manufactured using pultrusion, a continuous process in which fiber reinforcements are saturated with resin, pulled through a heated die of the desired shape, and cured. The result is a rigid, precisely dimensioned structural shape that can be cut, drilled, and assembled without heavy machinery.

Key Advantages Over Traditional Materials:

Do not corrode like steel

Weigh significantly less while maintaining high strength

Require minimal maintenance over decades of use

Fiberglass Round Rod

FRP ProfilesSquare Fiberglass Rod

FRP ProfilesFiberglass Flat Rods

FRP Profiles

Common Shapes of FRP Profiles

FRP profiles are available in a wide variety of cross-sectional shapes to suit different engineering and architectural needs. Common examples include:

1. I-Beams

Function: Used for primary structural support in frames and platforms.

Benefit: High load-bearing capacity with minimal weight.

2. Channels (C-Shapes)

Function: Ideal for framing, edge protection, and secondary structural members.

Benefit: Easy to install and connect to other components.

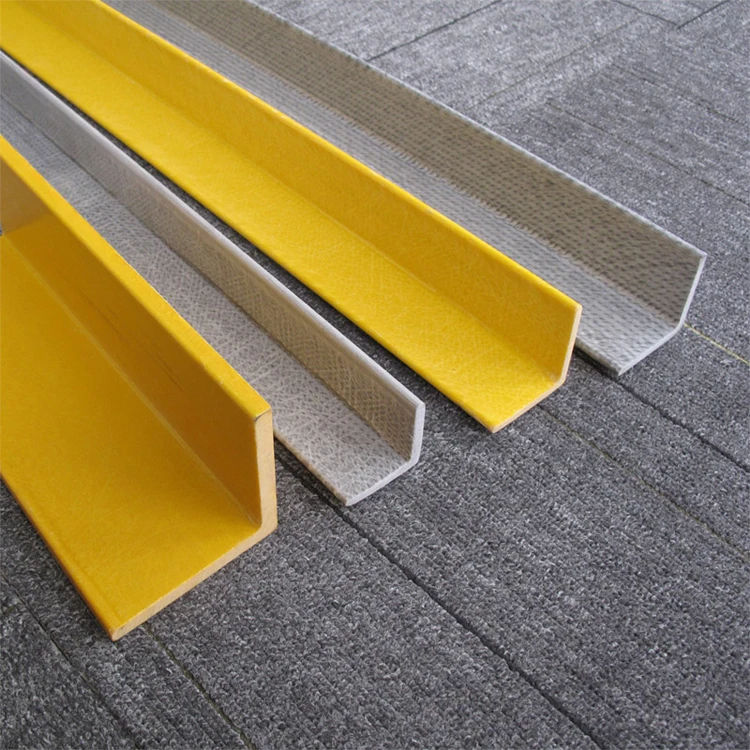

3. Angles (L-Shapes)

Function: Corner reinforcement, bracing, and support structures.

Benefit: Lightweight yet strong for stability in joint areas.

4. Tubes (Square, Rectangular, or Round)

Function: Railing systems, posts, and closed structural members.

Benefit: Excellent torsional resistance and protection of internal components.

5. Flat Bars & Rods

Function: Bracing, spacers, and flat surface reinforcements.

Benefit: Simple shapes for versatile uses.

6. Custom Profiles

Function: Designed to specific dimensions or functional requirements.

Benefit: Tailored solutions for specialized applications.

Properties of FRP Profiles

The success of FRP profiles comes from their unique combination of material and structural properties.

1. Lightweight but Strong

FRP profiles offer a superior strength-to-weight ratio compared to steel or aluminum, allowing easier handling, reduced transport costs, and simpler installation without sacrificing structural performance.

2. Corrosion and Chemical Resistance

FRP resists rust, rot, and chemical attack, making it ideal for marine docks, chemical plants, and wastewater treatment facilities.

3. Electrical and Thermal Insulation

Unlike metals, FRP is non-conductive, improving safety in electrical environments. It also has low thermal conductivity, reducing heat transfer.

4. Dimensional Stability

FRP does not warp, shrink, or swell due to moisture or temperature fluctuations, ensuring long-term structural accuracy.

5. Low Maintenance

No painting, galvanizing, or rust-proofing is required. Only occasional cleaning and inspection are necessary.

6. Design Flexibility

The pultrusion process allows precise control over fiber orientation and shape, meaning engineers can design profiles with specific load capabilities and geometric complexity.

Structural Benefits of FRP Profiles

FRP profiles offer several performance benefits that directly impact project efficiency and lifespan:

1. Superior Strength-to-Weight Ratio

Light enough to handle manually yet strong enough for heavy-duty use, FRP reduces the need for heavy lifting equipment and lowers structural dead load.

2. Longevity in Harsh Environments

In applications where steel would corrode in just a few years, FRP maintains strength for decades, significantly reducing lifecycle costs.

3. Lower Installation Costs

Because they are easy to cut, drill, and assemble with standard tools, FRP profiles reduce labor time and costs during installation.

4. Safety Enhancements

FRP’s non-conductive nature and slip-resistant surface options improve workplace safety in high-risk areas like electrical substations and marine decks.

5. Reduced Maintenance

Fewer repairs and minimal upkeep lead to predictable long-term operating costs.

Applications of FRP Profiles

FRP profiles are used across industries for both new construction and retrofits:

Construction: Frameworks, roofing supports, ladders, and walkways.

Marine: Piers, docks, and offshore platform structures.

Chemical Processing: Corrosion-resistant frames, tanks, and platforms.

Water Treatment: Walkways, covers, and support beams in corrosive conditions.

Utilities & Energy: Non-conductive platforms and ladders for substations.

Transportation: Lightweight bridges, platforms, and noise barrier frames.

FRP Profiles vs. Steel and Aluminum

| Feature | FRP Profiles | Steel | Aluminum |

|---|---|---|---|

| Corrosion Resistance | Excellent | Poor without coatings | Good, but prone to galvanic corrosion |

| Weight | Light | Heavy | Light |

| Strength-to-Weight | High | Moderate | High |

| Conductivity | Non-conductive | Conductive | Conductive |

| Maintenance | Low | High (painting/coating needed) | Low to moderate |

| Cost Over Lifecycle | Low | High | Moderate |

Maintenance Tips for FRP Profiles

Inspect periodically for cracks or impact damage.

Clean with mild detergent and water to remove dirt and debris.

Avoid prolonged exposure to high heat beyond design limits.

Replace damaged sections promptly to maintain structural integrity.

Conclusion

FRP profiles represent a modern engineering solution that combines the structural strength of metals with the corrosion resistance and light weight of advanced composites. With diverse shape options, outstanding mechanical and chemical properties, and proven performance in harsh environments, they are becoming the go-to choice for engineers seeking efficiency, safety, and long-term value.

By understanding the shapes, properties, and structural benefits of FRP profiles, project designers and builders can make informed choices that reduce costs, extend service life, and enhance performance.