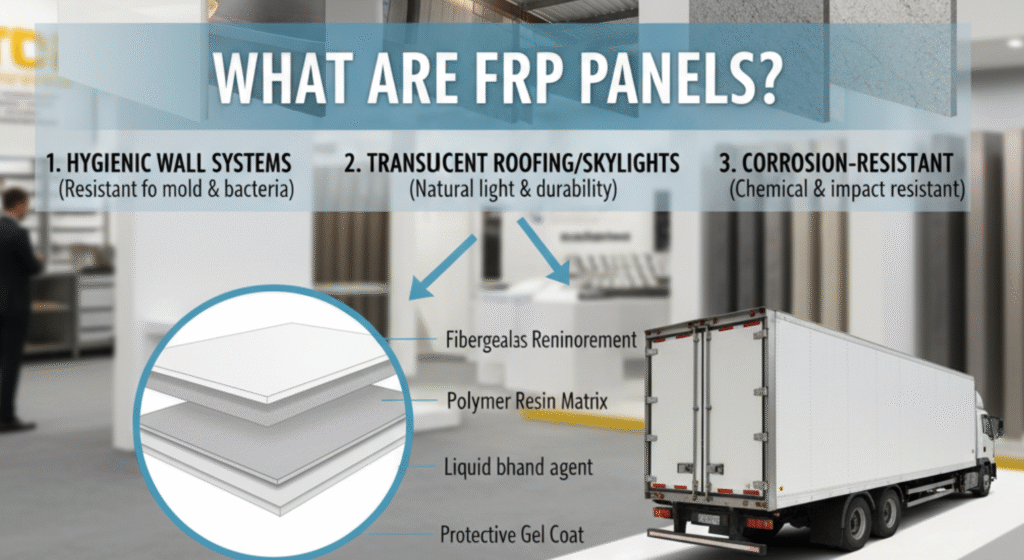

FRP panels, or Fiberglass Reinforced Plastic panels, are lightweight but strong wall and ceiling panels made from fiberglass and resin. They are durable, resistant to moisture and chemicals, and easy to clean—making them popular in kitchens, factories, hospitals, and outdoor spaces.

In this guide, you’ll learn what makes FRP panels special, how they’re used, and why they’re often the smarter long-term choice compared to materials like PVC, wood, or metal.

Key Features of FRP Panels

Methods of Measuring SoC

FRP offers a high strength-to-weight ratio. It can handle heavy loads and impacts without adding unnecessary weight to the structure. For example, in ceilings or partition walls, FRP panels add durability without overburdening the building frame.

Corrosion Resistance

Steel panels are easily corroded by chemicals or salt air, but FRP panels perform exceptionally well in harsh environments. This makes them ideal for chemical plants, wastewater treatment facilities, and coastal buildings where corrosion is a constant threat.

Moisture and Mold Resistance

Wood swells, cracks, or grows mold in damp areas. PVC tends to become brittle over time. FRP panels, with their resin coating and fiber-reinforced structure, are naturally resistant to moisture and mold growth, making them a perfect choice for kitchens, cold storage, and laboratories.

Electrical Insulation

FRP is non-conductive, which provides safety advantages in environments with high electrical risks, such as power stations or control rooms.

Design Flexibility

FRP panels can be customized in color, thickness, and surface texture. You can choose a smooth finish for easy cleaning or a textured finish for slip resistance in walkways and humid areas.

Low Maintenance

Unlike metal that needs anti-rust coatings or wood that requires polishing, FRP panels are almost maintenance-free. Their smooth surface is easy to wipe clean, even when exposed to oils, chemicals, or dirt.

How FRP Panels Are Made

FRP panels are created through a series of clear steps that combine strength with durability:

Step 1: Preparing the raw materials

Fiberglass is selected in the right form (chopped strands, woven fabric, or continuous fibers), and the resin system (polyester, vinyl ester, or epoxy) is chosen depending on the required performance.

Step 2: Arranging and saturating the fibers

The fiberglass is laid out and fully soaked with resin. Proper saturation ensures the fibers bond tightly and no weak spots or bubbles form.

Step 3: Molding and curing

The fiberglass is laid out and fully soaked with resin. Proper saturation ensures the fibers bond tightly and no weak spots or bubbles form.

Step 4: Cutting and finishing

The fiberglass is laid out and fully soaked with resin. Proper saturation ensures the fibers bond tightly and no weak spots or bubbles form.

Step 5: Quality inspection

Before being shipped, the panels are checked for thickness, strength, and surface quality to make sure they meet industry standards.

Applications of FRP Panels

Industrial Facilities

FRP panels are widely used in chemical plants, pharmaceutical factories, and wastewater treatment facilities. Their corrosion resistance makes them reliable in environments full of acidic vapors or cleaning agents.

Food and Hygiene Environments

Commercial kitchens, cold storage, and food processing facilities require surfaces that resist mold, are easy to clean, and withstand frequent disinfection. FRP fits perfectly into these requirements.

Public Buildings

In schools, hospitals, and shopping malls, walls and corridors face constant impacts from carts, equipment, and people. FRP panels’ durability ensures that they maintain a clean appearance for years.

Transportation and Outdoor Facilities

For bus stations, carports, and shelters, FRP panels provide lightweight yet durable protection against rain, wind, and UV exposure. They don’t rust or weaken under outdoor conditions.

Cost and Service Life

At first glance, FRP panels cost more than PVC or wood. However, they often last 15–20 years, compared to only 3–5 years for PVC in harsh conditions.

When you factor in initial cost + maintenance + replacement costs, FRP usually ends up being the more cost-effective solution in the long run. That’s why many industries prefer to invest in FRP despite the higher upfront price.

Industry Trends

Eco-Friendly Resins

New formulations reduce harmful emissions, making FRP safer for use in food-grade or medical environments.

Enhanced Weather Resistance

Advances in UV-resistant resins and coatings allow FRP panels to maintain strength and color in outdoor settings for decades.

Functional Surfaces

Future developments include self-cleaning and antibacterial coatings, further lowering maintenance and ensuring hygiene.

Conclusion

FRP panels combine lightweight construction, strength, corrosion resistance, and low maintenance in a single material. They are versatile enough to be used in industrial plants, food facilities, public spaces, and outdoor structures.

While the initial investment may be higher than alternatives like PVC or wood, the long service life and minimal upkeep make FRP panels a cost-effective and reliable choice for long-term projects.

If you’re looking for a durable, versatile, and low-maintenance material, FRP panels are definitely worth considering.