Railway Infrastructure

Our FRP solutions are designed to meet the demanding requirements of railway infrastructure, offering superior strength, corrosion resistance, and long service life in harsh environments.

- Home

- Application

- Railway Infrastructure

Industry Challenges in Railway Infrastructure

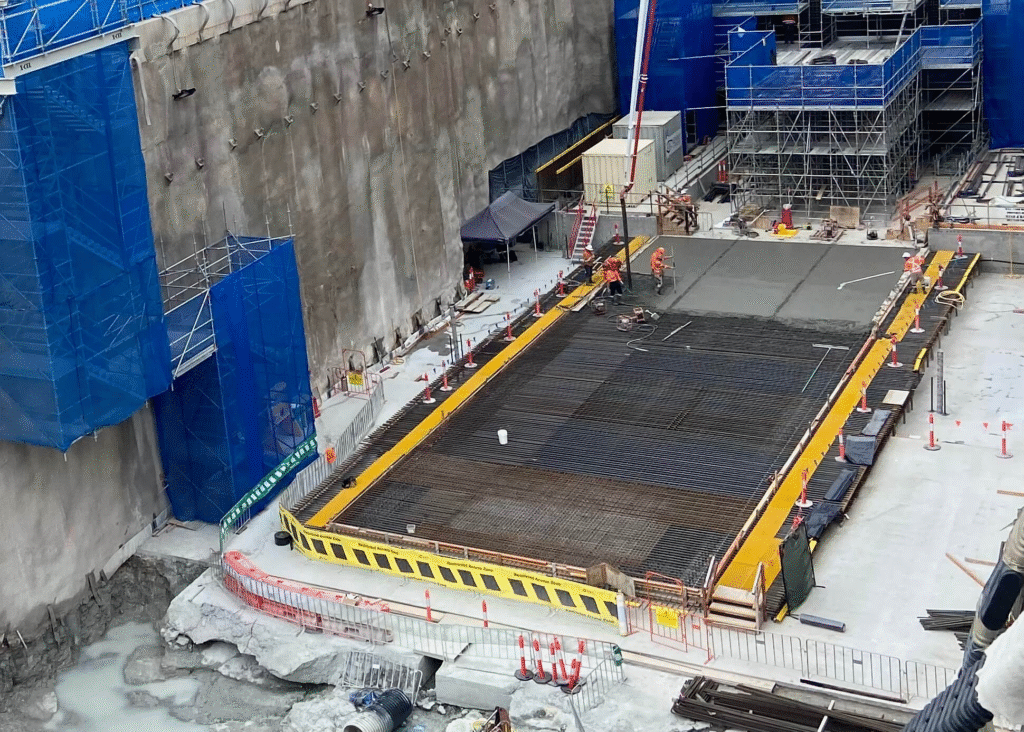

Railway infrastructure operates under some of the harshest conditions in the transportation sector. Constant exposure to moisture, temperature fluctuations, chemical contaminants, and heavy mechanical loads places severe stress on traditional construction materials. Steel components are prone to corrosion and require frequent maintenance, while concrete can crack or degrade under repeated freeze–thaw cycles.

In addition, many railway facilities—such as bridges, inspection walkways, and cable management systems—are installed in hard-to-reach areas, making repairs costly and disruptive to operations. Safety risks from slippery surfaces and electrical conductivity further complicate the selection of suitable materials. For operators and contractors, the challenge lies in finding a solution that combines durability, safety, and cost efficiency over the long term.

Why FRP is the Ideal Solution for Railways

Corrosion Resistance with Long-Term Reliability

FRP withstands moisture, salts, and chemical exposure without rusting, making it ideal for bridges, platforms, and other outdoor railway structures.

Lightweight for Faster, Safer Installation

Its low weight reduces transport and installation time, even in elevated or restricted-access areas, minimizing disruption to railway operations.

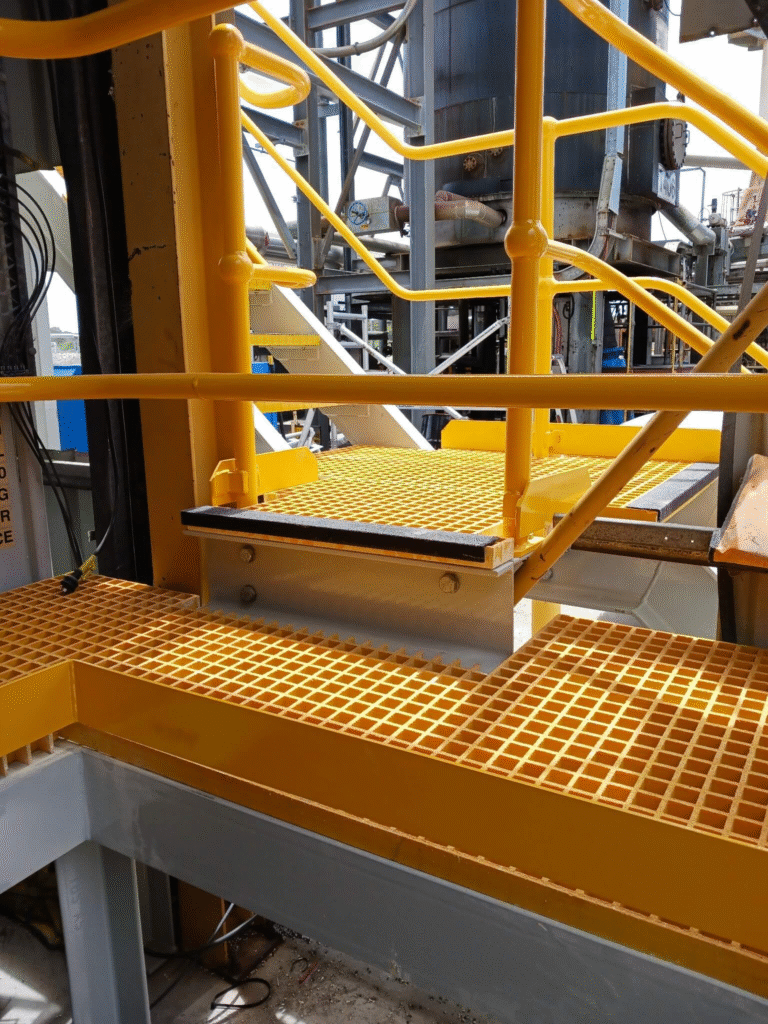

High Strength-to-Weight Ratio

Despite being lightweight, FRP provides exceptional load-bearing capacity for walkways, handrails, and cable support systems.

Built-In Safety Advantages

Non-conductive and available with anti-slip surfaces, FRP enhances worker safety near electrical systems and in wet or icy conditions.

One-stop FRP Solutions for Railway Infrastructure

DNK is a leading FRP manufacturer in China, providing comprehensive railway solutions. Our one-stop service covers the entire project lifecycle, including

Customized FRP product design based on railway infrastructure requirements.

Precision production with strict adherence to international standards.

Timely supply and technical guidance for smooth project execution.

Ongoing support to ensure long-term performance and safety.

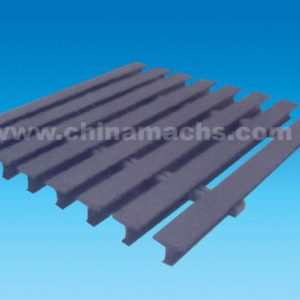

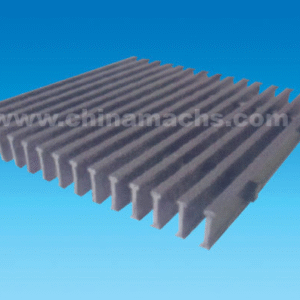

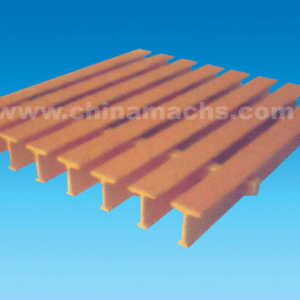

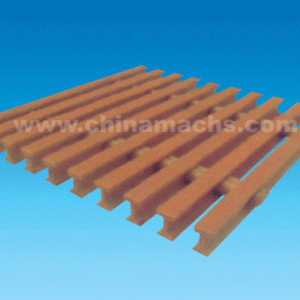

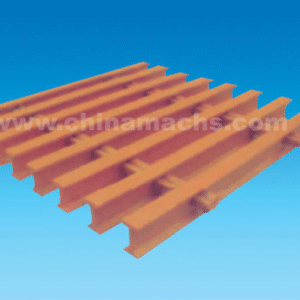

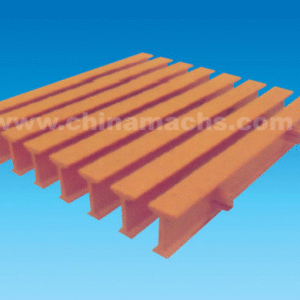

T-Bar 1″Deep 60%Open(T10-60 ADA)

FRP GratingT-Bar 1 1/2″Deep 17%Open(T15-17)

FRP GratingT-Bar 1″Deep 33%Open(T10-33)

FRP GratingT-Bar 1 1/2″Deep 17%Open(T15-17)

FRP GratingT-Bar 1 1/2″Deep 60%Open(IP15-60 ADA)

FRP GratingT-Bar 1″Deep 18%Open(T10-18)

FRP GratingT-Bar 1″Deep 35%Open(T10-35)

FRP GratingT-Bar 1″Deep 50%Open(T10-50)

FRP GratingT-Bar 1 1/2″Deep 33%Open(T15-33)

FRP GratingT-Bar 1″Deep 50%Open(T10-50)

FRP GratingT-Bar 1″Deep 40%Open(T10-40)

FRP GratingT-Bar 1″Deep 50%Open(T10-50)

FRP GratingT-Bar 1″Deep 60%Open(I10-60)

FRP GratingT-Bar 1/4″Deep 40%Open(I12-40)

FRP GratingT-Bar 1 1/2″Deep 40%Open(I15-40)

FRP GratingT-Bar 1 1/2″Deep 50%Open(I15-50)

FRP GratingT-Bar 1 1/2″Deep 60%Open(I15-60)

FRP GratingT-Bar 2″Deep 33%Open(T20-33)

FRP GratingT-Bar 3″Deep 40%Open(I30-40)

FRP GratingT-Bar 3″Deep 50%Open(I30-50)

FRP Grating