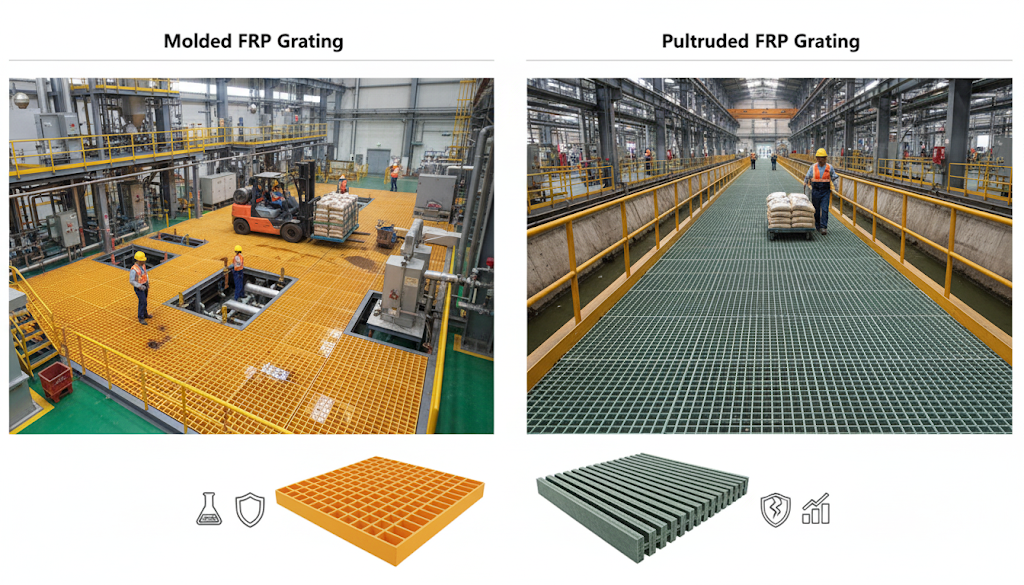

If you’re choosing between molded and pultruded FRP grating, here’s the simple rule of thumb:

Pultruded FRP Grating is the better choice when your project requires long spans and heavy loads, such as industrial platforms, traffic walkways, or warehouse passages.

Molded FRP Grating is the smarter option when you need superior corrosion resistance, impact strength, and bi-directional load bearing, such as in chemical plants, wastewater treatment facilities, and inspection platforms.

Once you understand this basic guideline, the rest is about details—let’s explore the differences so you can make the right decision with confidence.

| Feature | Pultruded FRP Grating | Molded FRP Grating |

|---|---|---|

| Load & Span | ⭐⭐⭐⭐⭐ High strength, ideal for long spans and heavy loads | ⭐⭐ Suitable for short spans, limited load capacity |

| Corrosion Resistance | ⭐⭐⭐ Moderate, depends on resin system | ⭐⭐⭐⭐⭐ Excellent performance, ideal for highly corrosive environments |

| Impact Resistance | ⭐⭐ Relatively brittle, average impact resistance | ⭐⭐⭐⭐⭐ Strong toughness, excellent impact resistance |

| Cost | ⭐⭐⭐ Higher initial cost, more economical long term | ⭐⭐⭐⭐ Lower initial cost, good for limited budgets |

Manufacturing Process and Structure

Molded FRP grating is produced by layering fiberglass and resin in a mold. Once cured, it becomes a solid panel with no mechanical joints. This design provides bi-directional strength and allows it to distribute loads evenly.

Pultruded FRP grating is made by pulling fiberglass rovings through resin and then through a heated die. The result is strong bearing bars, later joined with cross rods. Because the fibers run lengthwise, pultruded grating offers unidirectional strength that is especially effective in one main direction.

Strength and Span Performance

Molded grating performs well under impact and when loads come from multiple directions. It is tough and resilient, making it suitable for short to medium spans.

Pultruded grating, in contrast, delivers higher load capacity along the bearing bar direction. It is the preferred choice for long spans and heavy-duty applications, such as areas where forklifts or machinery are in use.

Corrosion Resistance and Service Life

Both molded and pultruded grating outperform steel in corrosive environments, but they focus on different strengths.

Molded grating contains a higher ratio of resin, which enhances its ability to resist chemicals like acids, alkalis, and saltwater. This makes it ideal for wastewater facilities, chemical plants, or marine projects.

Pultruded grating, with more fiberglass content, offers superior strength but its corrosion resistance depends on the specific resin system used. It can still perform well, but the choice of resin becomes a critical factor.

Surface Options and Safety

Molded grating is available with multiple surface finishes, such as meniscus tops, grit layers, smooth surfaces, or specialized coatings. This variety gives engineers more flexibility in meeting safety and slip resistance needs.

Pultruded grating has fewer surface variations. However, its standard grit finishes still provide reliable slip resistance in most industrial and commercial settings. For projects that need customized anti-slip surfaces, molded grating is often the preferred option.

Cost and Maintenance

Molded grating usually comes with a lower initial price. It also resists corrosion well, which reduces maintenance in harsh environments. This makes it attractive for projects with limited budgets.

Pultruded grating costs more upfront. But over time, it proves more economical for heavy-duty projects because it reduces the need for additional support structures and delivers longer service life under heavy loads.

Typical Applications

Molded FRP grating is widely used in chemical processing plants, wastewater treatment facilities, and maintenance walkways. Its corrosion resistance and toughness make it suitable for environments with frequent chemical exposure.

Pultruded FRP grating is commonly installed in industrial platforms, transportation corridors, docks, and warehouses. Its strength and load capacity allow it to handle long spans and heavy equipment traffic.

Final Thoughts

The decision between molded and pultruded FRP grating depends on the environment, load demands, and budget.

Molded grating is best when corrosion resistance and impact strength are your top priorities. Pultruded grating is best when long spans and high load capacity matter most.

There is no absolute “better” choice, only the option that best fits your project. By evaluating your specific requirements, you can confidently choose the FRP grating that ensures long-term performance and value.