Fencing & Screening

- Home

- Application

- Fencing & Screening

Why Use FRP Materials for Fencing & Screening

Fencing and screening in industrial, commercial, and public environments must withstand constant exposure to weather, moisture, and, in some cases, corrosive chemicals. Traditional materials such as steel can rust, and wood can warp or rot, leading to frequent maintenance and reduced service life.

FRP (Fiber Reinforced Plastic) offers a durable, low-maintenance alternative. It is completely resistant to corrosion, moisture absorption, and UV degradation, ensuring long-lasting structural integrity and appearance. FRP’s lightweight nature allows for easier handling and faster installation without compromising strength. In addition, it can be manufactured in a variety of colors and designs, making it suitable for both functional and aesthetic applications.

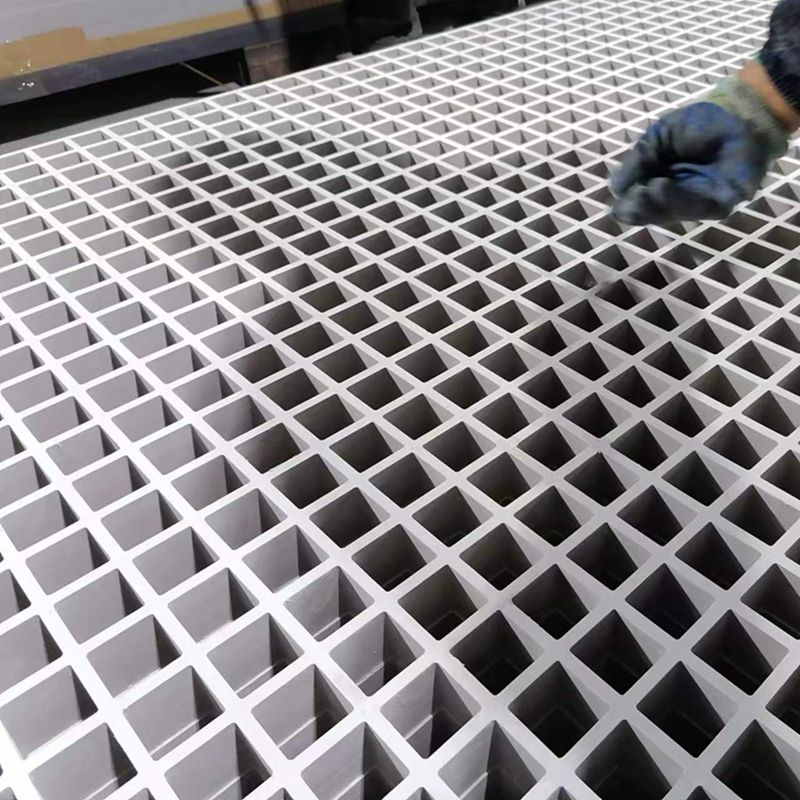

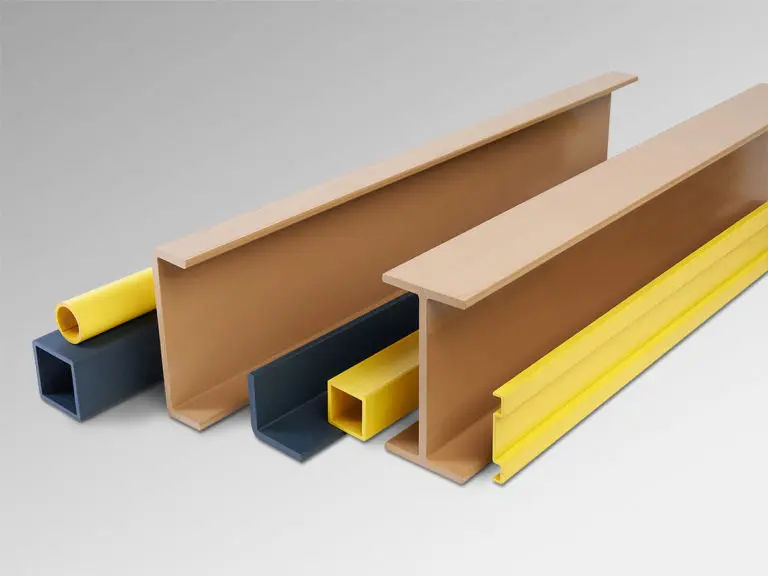

FRP Materials Used in Fencing & Screening

Our factory manufactures a wide range of FRP fencing and screening materials designed for long-lasting performance in industrial, commercial, and public environments. With extensive experience supplying projects in coastal areas, industrial plants, and public facilities, we deliver corrosion-resistant, UV-stable, and low-maintenance solutions that meet diverse design and safety requirements.

Custom FRP Fencing Manufacturing Process

Specification Confirmation

Receive detailed drawings and requirements from the client, including dimensions, design style, color, and performance standards.Material Selection & Mould Preparation

Choose suitable FRP resin, reinforcement fibers, and surface finishes, then prepare precision moulds for accurate shaping.Manufacturing & Quality Inspection

Produce FRP fencing components using advanced moulding or pultrusion processes, followed by strict inspections for strength, corrosion resistance, and UV stability.Finishing & Packaging

Apply any required surface textures or coatings, then package securely to ensure safe delivery to the project site.