Custom Pultrusion Service — Tailored FRP Profiles

Looking for FRP profiles that standard catalogs can’t deliver? Our Custom Pultrusion Service helps you create unique fiberglass solutions — from structural strength to chemical resistance — all tailored to your industry needs.

FRP Profiles Showcase

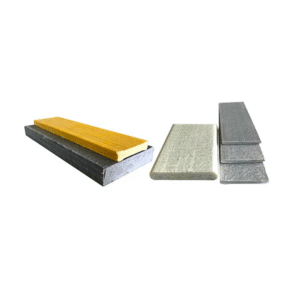

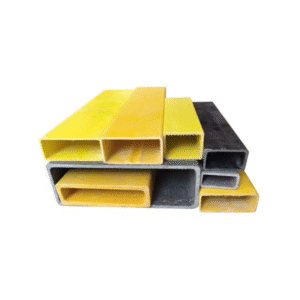

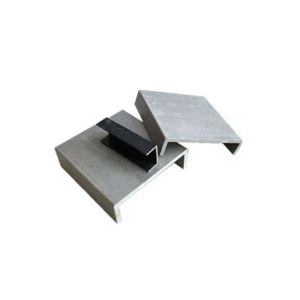

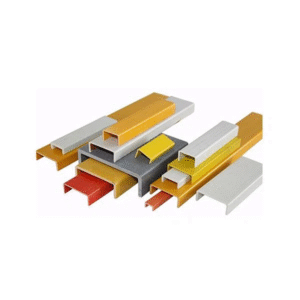

High-strength, lightweight, and corrosion-resistant FRP profiles — available in standard and custom shapes to fit diverse structural applications.

Fiberglass Round Rod

FRP ProfilesSquare Fiberglass Rod

FRP ProfilesFiberglass Flat Rods

FRP ProfilesFiberglass Angle Iron

FRP ProfilesFiberglass Rectangular Tube

FRP ProfilesFRP Round Tube

FRP ProfilesFRP Square Tube

FRP ProfilesStructural Fiberglass FRP Channel

FRP ProfilesFRP C Channel

FRP ProfilesFRP L Angle

FRP Profiles

Our Custom Pultrusion Capabilities

| Category | Customization Options |

|---|---|

| Profile Shapes | ✅ Round tubes, ✅ Square tubes, ✅ I-beams, ✅ Channels, ✅ Angles, T-bars, Z-shapes, ✅ Custom complex profiles |

| Materials | ✅ Fiberglass (E-glass, S-glass), ✅ Carbon fiber, ✅ Aramid fiber |

| Resins | ✅ Polyester, ✅ Vinyl ester, ✅ Epoxy, ✅ Phenolic |

| Colors & Surface Finish |

✅ Yellow, Grey, Green, Black, Custom RAL colors; ✅ Smooth or Gritted surface; ✅ UV resistant; ✅ Anti-static |

| Dimensions | ✅ Length up to 12m+; ✅ Custom wall thickness; ✅ Industry-standard tolerances |

| Performance | ✅ Fire-retardant (ASTM E84, UL 94); ✅ High strength; ✅ Corrosion resistance; ✅ Electrical insulation |

Additional Information

| Category | Customization Options |

|---|---|

| Standards |

✅ ASTM ✅ ISO ✅ EN ✅ GB ✅ Custom international standards |

| Applications |

✅ Construction and Infrastructure ✅ Electrical and Utilities ✅ Marine and Offshore ✅ Transportation ✅ Chemical plants ✅ Cooling towers ✅ Walkways, platforms, ladders ✅ Railings and fencing ✅ Custom engineering solutions |

| Delivery Options |

✅ Standard lengths ✅ Cut-to-size ✅ Pre-assembled kits ✅ Export packaging |

| Value-added Services |

✅ CNC machining ✅ Drilling & slotting ✅ Surface treatment ✅ Assembly support ✅ Technical consultation |

FAQ – Custom Pultrusion Service

Q: How can I get a design review and quotation for a custom FRP profile?

Simply provide us with your project requirements (dimensions, application, and performance needs). Our engineers will review your design and offer a tailored quotation. Even if you don’t have complete details, our technical team can guide you through the process step by step.

Q: What’s the difference between “custom profiles” and standard FRP profiles?

Standard FRP profiles (like I-beams, channels, and tubes) follow predefined shapes and resin systems with known performance data.

Custom profiles, however, are designed specifically for your application — including shape, resin matrix, reinforcement type, and performance properties — to meet unique strength, corrosion resistance, or insulation needs.

Q: Can FRP profiles be customized for corrosion or UV resistance?

Yes. We can enhance durability through resin selection, UV inhibitors, protective coatings, or color pigments. This ensures reliable performance even in harsh outdoor or chemical environments.

Q: Is it possible to choose custom colors?

Absolutely. Standard colors are available, and we can also match Pantone or RAL codes or develop special pigments. Note that the final shade may vary slightly depending on resin and reinforcement.

Q: What about the surface finish?

Surface appearance can be tailored to your needs: smooth, gritted, anti-static, or coated. During the design review, we’ll recommend the best finish for your application.

Q: How are visual standards for custom profiles defined?

We work with you to establish clear visual acceptance standards. If no specification is provided, we apply our internal quality guidelines to ensure consistency and reliability.

Q: Who handles the tooling for custom pultrusion?

We provide a one-stop solution — from profile design to pultrusion die manufacturing. Our team manages mold design, ordering, and implementation so you can move quickly into production.

Q: What if I don’t have all the technical details ready?

No problem. With years of pultrusion expertise and a team of engineers, we can help translate your concept into a workable FRP profile design. We also provide CAD support, material selection advice, and prototyping to refine your product.