Construction is changing fast. Builders need materials that are strong, light, and durable. One option that is becoming very popular is FRP—Fiber Reinforced Polymer. It is strong but not heavy. It resists rust and chemicals. It can be shaped into many forms. Because of this, FRP is now used in many buildings and infrastructure projects. But what does FRP really mean, and why is it useful in construction?

What Is FRP?

FRP stands for Fiber Reinforced Polymer. It is a composite material. It is made of two parts:

A polymer matrix like epoxy, polyester, or vinyl ester.

Fibers like glass, carbon, or aramid.

The polymer binds everything together and protects against water and chemicals. The fibers give the material strength and stiffness. Together, they create a product that is light, strong, and long-lasting.

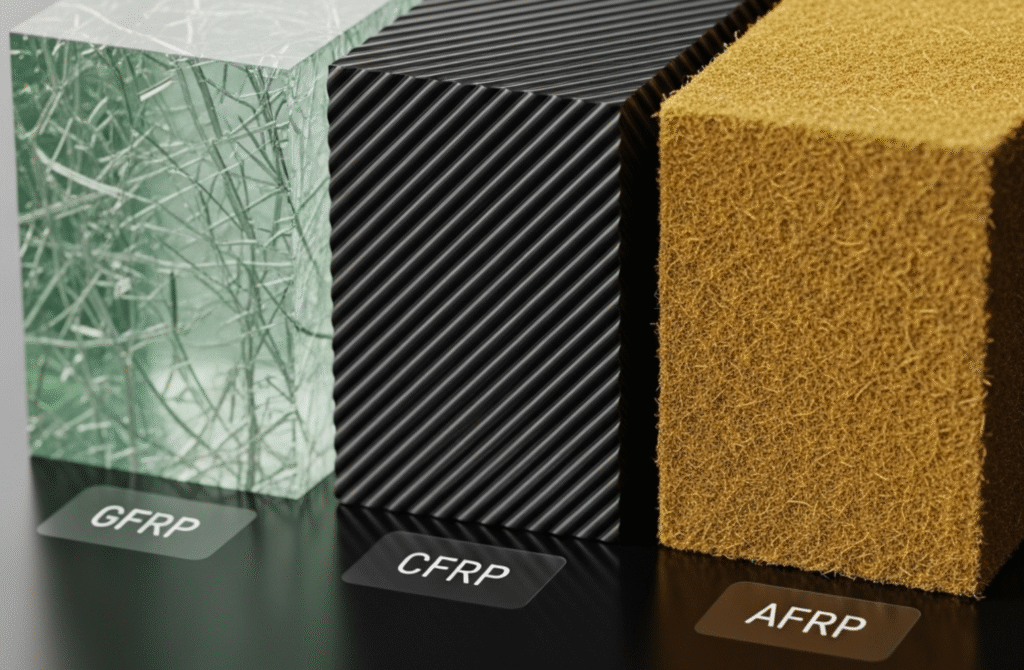

Types of FRP in Construction

Glass Fiber Reinforced Polymer (GFRP)

The most common type. It offers a good balance between cost and performance. Often used in concrete reinforcement and cladding.

Carbon Fiber Reinforced Polymer (CFRP)

Very strong and stiff. Often used to strengthen structures or in seismic upgrades. More expensive than GFRP.

Aramid Fiber Reinforced Polymer (AFRP)

Best known for impact resistance. It works well in places with vibration or repeated loads.

The Role of FRP in Construction

Reinforcement in Concrete

FRP bars are often used instead of steel rebars. They are ideal for bridges, tunnels, and marine projects. Unlike steel, they do not rust. This makes the structure last much longer.

Repair and Retrofitting

Old buildings can be wrapped or lined with FRP sheets. This helps restore strength. It also improves resistance to earthquakes and heavy loads without adding much weight.

Exterior Use

FRP panels are used on facades, cladding, and walls. They resist rain, sun, and temperature changes. They can also look like wood or stone.

Interior Use

FRP panels are common in hospitals, kitchens, and clean rooms. They are smooth, non-porous, and easy to clean.

Roofing and Skylights

FRP roofing lets in natural light. It cuts down on energy use. Skylights made of FRP resist UV rays and impacts while keeping buildings bright.

Special Structures

FRP is also used in walkways, bathrooms, and pedestrian bridges. Its low weight and strength make it easy to install and maintain.

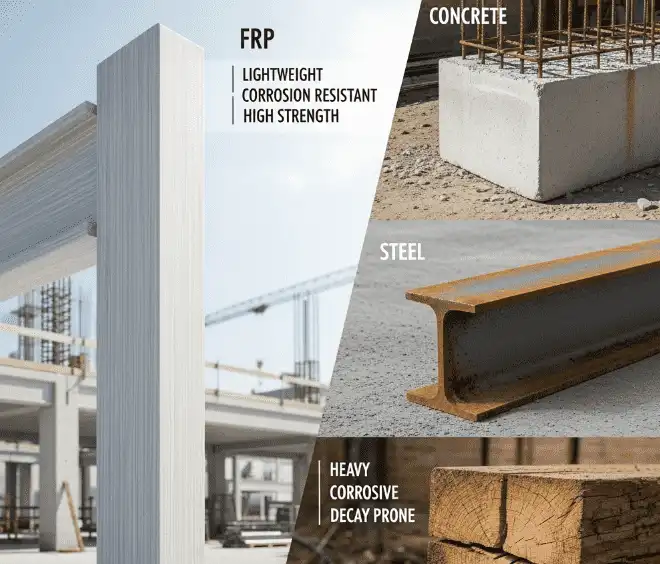

Comparing FRP to Traditional Materials

Steel: Strong but heavy and prone to rust. FRP is strong too, but it does not corrode.

Wood: Attractive but can rot or be damaged by insects. FRP can look like wood but lasts much longer.

Concrete: Durable but very heavy and rigid. FRP is lighter and easier to shape.

Advantages of FRP

Light weight with high strength.

Resistant to rust and corrosion.

Can be made into many shapes and finishes.

Long service life with little maintenance.

Non-conductive and non-magnetic, useful in special projects.

Challenges of FRP

Higher upfront cost compared to steel or wood.

Some types can be brittle and have less flexibility than steel.

Fire resistance can be a concern; coatings may be needed.

Harder to recycle compared to steel.

Lesser-Known Facts About FRP

Not just a name: FRP means the type of material, not a single product. Different fibers and polymers change its performance.

Thermal match with concrete: In some cases, FRP expands and contracts closer to concrete than steel. This reduces cracking from temperature changes.

Long life span: Some FRP-reinforced bridges are expected to last more than 75 years.

Non-conductive: FRP does not carry electricity. It is good for use in hospitals, power plants, and labs.

Conclusion

FRP—Fiber Reinforced Polymer—is changing modern construction. It is light, strong, durable, and flexible in design. It is used for concrete reinforcement, building repairs, facades, hygienic interiors, and energy-saving roofs.

It may not replace steel or concrete everywhere. But in many cases, FRP offers clear advantages: lower maintenance, longer life, and greater design freedom. As the construction industry looks for sustainable and high-performance materials, FRP is becoming one of the smartest choices for the future.