When designing walkways, platforms, or stair treads, you may come across the terms FRP grating and GRP grating. Are they different products, or simply two names for the same thing? This guide breaks down the differences, highlights where the terms overlap, and helps you choose the right solution for your project.

What Are FRP and GRP?

FRP (Fibre/Fiber Reinforced Plastic) is a broad term that refers to any polymer material reinforced with fibers. These fibers can be glass, carbon, aramid (Kevlar), or even basalt, and the resin matrix may be polyester, vinyl ester, epoxy, or phenolic.

GRP is a subset of FRP that uses glass fibers as the reinforcement. In other words, all GRP is FRP, but not all FRP is GRP.

In the UK and EU, the term GRP is more common, with standards like BS 4592-6 specifically covering GRP open-mesh gratings. In the US and international markets, FRP is the preferred term and is used interchangeably with fiberglass grating.

Key Differences Between FRP and GRP

FRP is a broader category that covers all types of fiber-reinforced plastics. It includes GRP (glass fiber), CFRP (carbon fiber), and AFRP (aramid fiber). GRP specifically uses glass fibers, making it the most common and cost-effective choice for industrial gratings.

The main difference comes down to material options and performance flexibility: FRP can be specified with higher-performance reinforcements such as carbon fiber for aerospace or automotive applications where high strength-to-weight ratio is critical. GRP, on the other hand, delivers excellent corrosion resistance, mechanical strength, and cost-efficiency—ideal for platforms, walkways, and stairs in chemical plants, wastewater facilities, and general industrial environments.

Another difference is terminology by region: GRP is the go-to term in the UK/EU, whereas FRP dominates specifications and catalogs in the US. Knowing which term is used locally helps you match standards and avoid confusion in procurement.

Shared Advantages

Regardless of whether you call it FRP or GRP, both share several benefits:

High strength-to-weight ratio – Lighter than steel, easier and safer to install

Corrosion resistance – Ideal for chemical, marine, or wet environments

Low maintenance – No need for painting, no rusting

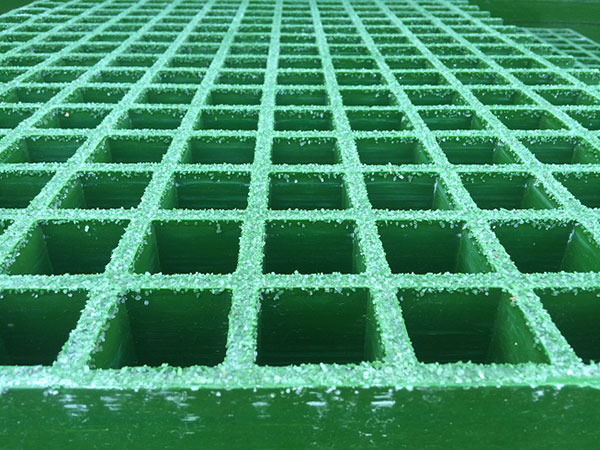

Slip resistance – Available with grit-top or textured finishes to improve safety

Manufacturing Methods Matter More

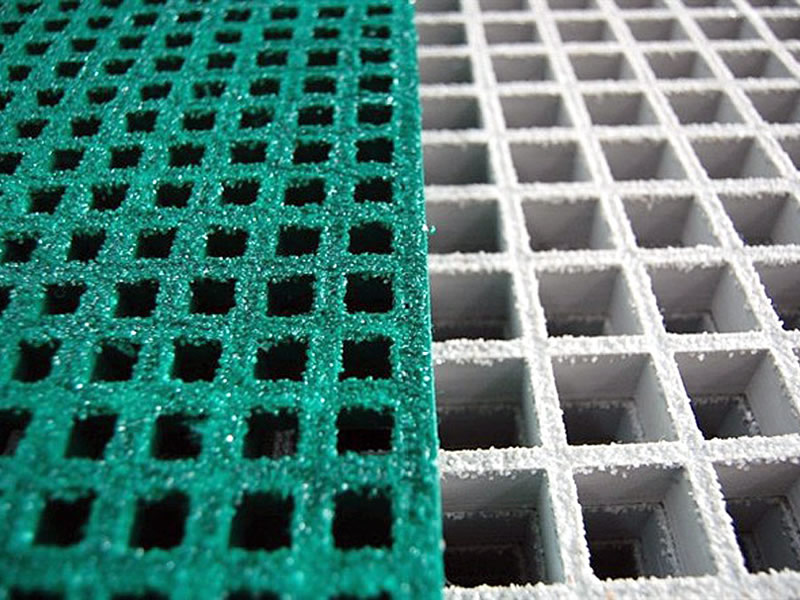

The choice between molded grating and pultruded grating often has a bigger impact than whether you specify FRP or GRP.

Molded grating has higher resin content, great impact resistance, and can be easily cut on-site. It’s a good choice for walkways, stair treads, and areas with frequent foot traffic.

Pultruded grating has higher glass content and superior unidirectional strength, making it ideal for heavy-duty platforms, large spans, or equipment areas where deflection limits are critical.

Conclusion

GRP is simply FRP that uses glass fibers as reinforcement. For most industrial flooring applications, FRP and GRP gratings are essentially the same thing. Focus less on the name and more on the manufacturing type, resin system, and performance data to ensure safety, compliance, and long-term durability.

FAQ

1. Are FRP and GRP the same?

Not exactly. FRP is a general category; GRP is FRP made with glass fibers. Most industrial gratings are GRP, which is why the terms are often used interchangeably.

2. Which one is more durable?

GRP gratings are highly durable in corrosive environments and require very little maintenance. For special cases (e.g., extreme temperatures or very high loads), other FRP types may be used.

3. What’s the difference between molded and pultruded grating?

Molded grating has higher resin content and is impact-resistant, great for people-heavy areas. Pultruded grating offers longer spans and higher strength for heavy-duty platforms.

4. Do FRP/GRP gratings need extra corrosion protection?

No. They are inherently corrosion-resistant and will not rust, making them ideal for wet or chemically aggressive environments.

5. Which term should I use when specifying products?

Follow local practice—GRP in UK/EU specs, FRP in US/global projects. To avoid confusion, you can write “FRP (GRP Fiberglass) Grating.”