Industrial platforms, walkways, and trench covers depend on strong, safe, and durable grating. Choosing the right grating material impacts worker safety, maintenance costs, and the total life cycle cost of a facility. For decades, steel grating has been the default choice — but fiberglass reinforced plastic (FRP) grating has emerged as a competitive alternative. So, which is the better option for your project? This guide compares FRP and steel gratings in detail to help you make an informed decision.

What Are FRP and Steel Gratings?

FRP Grating

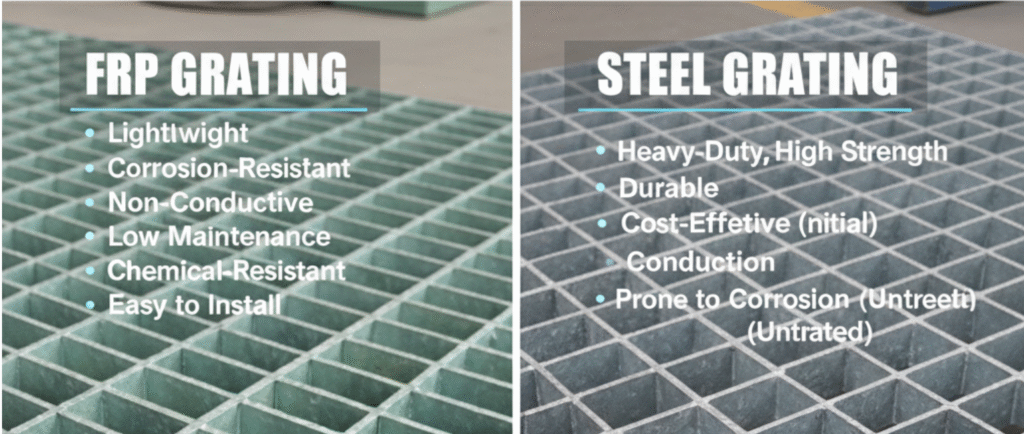

FRP grating is made from continuous fiberglass rovings combined with a polymer resin (polyester, vinyl ester, or epoxy) to form a strong, lightweight, corrosion-resistant panel. It comes in two major types: molded grating, which offers bi-directional strength, and pultruded grating, which provides high stiffness in one direction for heavy-load applications.

Steel Grating

Steel grating is fabricated from carbon steel, galvanized steel, or stainless steel through welding or press-locking. It is known for its excellent strength, rigidity, and load-carrying capacity. However, it is susceptible to corrosion unless coated or galvanized.

Key Comparison Factors

Corrosion Resistance and Durability

FRP is inherently corrosion-resistant, making it ideal for environments with moisture, salt, or chemical exposure. It does not rust, rot, or require painting. Preet Grating reports that FRP gratings can last 20–25 years in aggressive conditions with minimal maintenance.

Steel grating, unless stainless or properly coated, may begin to corrode within 3–5 years in wastewater plants, coastal facilities, or chemical processing plants. Corrosion not only weakens the grating but also creates a safety hazard due to sharp edges and structural failure.

Corrosion Resistance and Durability

FRP’s density is roughly 1/4–1/6 that of steel (14-21 kN/m³), which makes it significantly lighter. This means easier handling, faster installation, and reduced structural support requirements.

| Property | FRP Grating | Steel Grating |

|---|---|---|

| Density | ~1.8 g/cm³ | ~7.85 g/cm³ |

| Typical Weight (per m²) | 9–12 kg | 35–45 kg |

| Installation | Can be lifted manually | Requires lifting equipment |

| Flexural Strength | 200–300 MPa (depends on resin & glass content) | 250+ MPa |

Steel, however, still holds an edge in absolute stiffness and impact resistance under very heavy loads. For forklift traffic or mining applications, steel may remain the preferred option.

Safety and Performance

One of FRP’s strongest advantages is electrical safety. It is non-conductive and has a dielectric strength exceeding 10 kV, making it ideal for power plants and substations. It also provides excellent slip resistance, even in wet or oily conditions, reducing the risk of workplace accidents.

Steel grating is conductive and requires proper grounding to mitigate shock risk. It can also become slippery when wet unless treated with serrations or anti-slip coatings, which add cost and require maintenance.

Maintenance and Life Cycle Cost

FRP is nearly maintenance-free — it does not need repainting or galvanizing, and cleaning is easy. This reduces shutdowns and labor costs.

Steel grating requires regular inspection, rust removal, and recoating. Over a 10-15 year period, these costs add up and can exceed the initial savings of using steel.

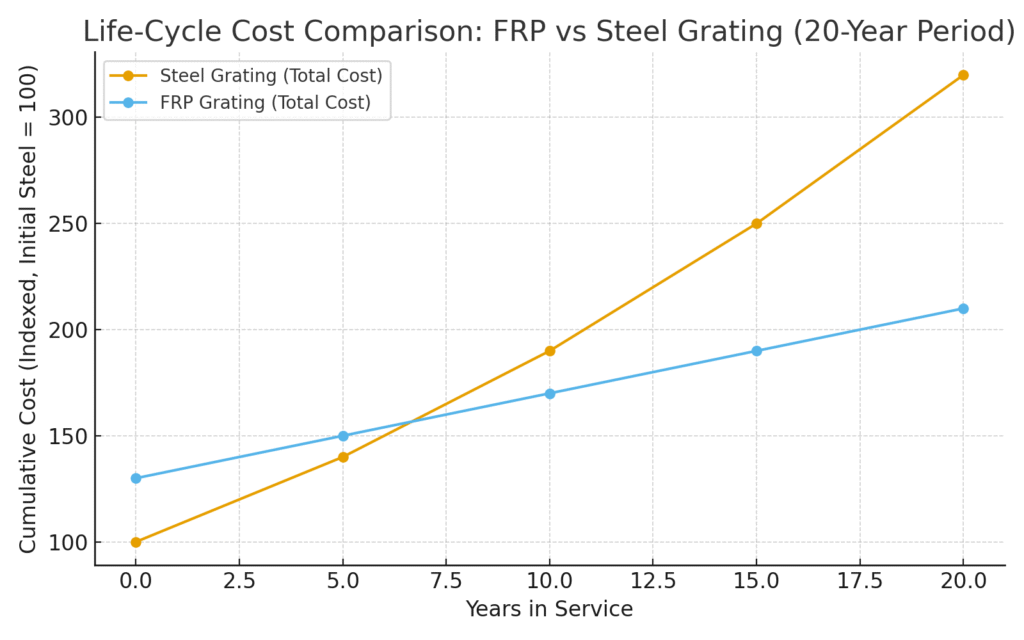

Life-Cycle Cost Example:

A wastewater treatment plant study showed that although FRP’s upfront material cost was about 30–40% higher, its total cost of ownership over 20 years was 25–30% lower due to reduced maintenance and replacement frequency.

FRP grating’s total cost grows slower over time, while steel grating’s cost rises sharply due to maintenance and replacement.

Fire and Temperature Resistance

FRP’s fire performance depends on the resin system. Modern FRP gratings can meet ASTM E84 Class 1 flame spread ratings when fire-retardant resins are used. However, FRP can lose strength above 120 °C and may soften under prolonged heat.

Steel can withstand higher service temperatures but loses strength rapidly during a fire unless coated with intumescent fire protection. When fire safety is critical, engineers should review standards (e.g., NFPA, BS 476) before finalizing material selection.

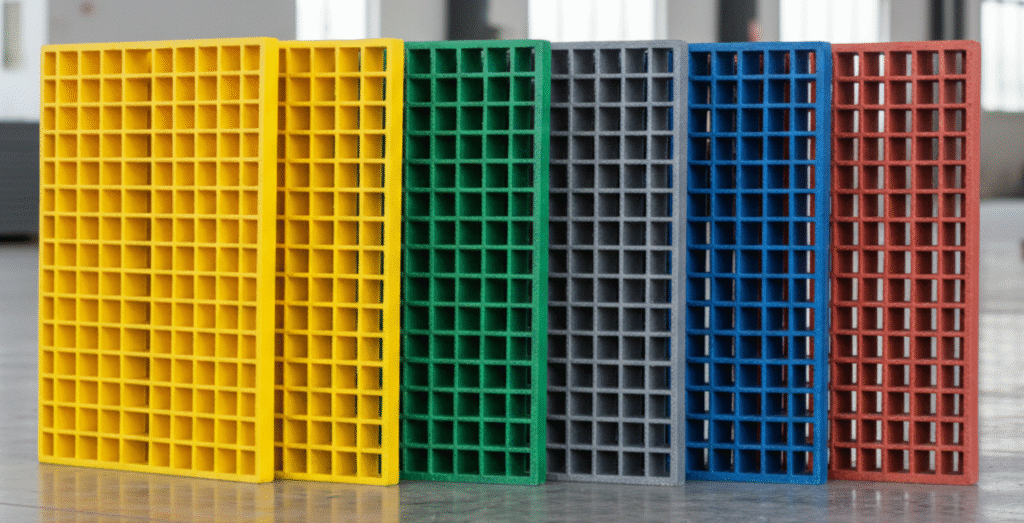

Customization and Aesthetics

FRP offers superior design flexibility: it can be manufactured in different colors, surface textures, panel sizes, and load ratings. This helps with visual coding (e.g., yellow for safety walkways) and compliance with facility design requirements.

Steel can be galvanized, painted, or powder-coated, but color options are limited and surface finish deteriorates over time.

Typical Applications

FRP Grating is ideal for:

Wastewater treatment plants

Chemical processing facilities

Food & beverage plants (non-slip, easy to clean)

Coastal and offshore platforms

Electrical substations or areas requiring non-conductivity

Steel Grating is preferred for:

Heavy traffic floors (forklift lanes, loading docks)

Mining and aggregate plants

Applications with extreme point loads

Projects with very tight budgets and short design life

Decision Framework: How to Choose for Your Project

When deciding between FRP and steel, consider the following five questions:

How corrosive is the environment? If there’s high humidity, salt spray, or chemical exposure, FRP is the safer choice.

What are the load requirements? For heavy vehicle traffic or very high point loads, steel might be necessary.

What is the expected service life? For projects with 15–25 year horizons, FRP minimizes life-cycle costs.

Are there electrical or safety concerns? FRP’s non-conductive, slip-resistant nature offers superior worker safety.

What is the available budget? FRP has a higher upfront cost, but may save significantly in maintenance and replacement.

Conclusion

FRP grating and steel grating both have their place in industrial projects — but they are not equal choices. For corrosive, safety-critical, or long-term facilities, FRP grating is generally the better option, offering lower life-cycle costs, superior corrosion resistance, and improved worker safety.

Steel grating remains the practical choice for extreme heavy-load areas or budget-tight, short-term installations where its high stiffness and low upfront cost are decisive.

Bottom line: For most modern industrial projects focused on reliability, reduced maintenance, and safety compliance, FRP grating is the smarter investment.