U Clip

- Customizable Options – Tailored size, resin type, and surface finish to meet your project needs.

- Factory-Direct Pricing – Save costs with direct production from our source factory.

- Free Sample Design – Get a sample or design validation before bulk production.

- Global Quality Supply – Reliable quality and on-time delivery worldwide.

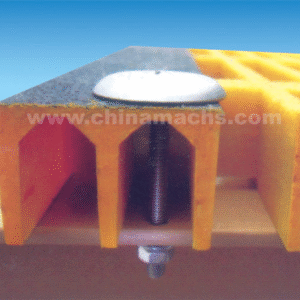

U Clip

U clip are used as special connectors for FRP gratings. They are made of stainless steel 304, which is resistant to corrosion and high strength. Its shape is divided into: M-type, U-type, C-type, L-type, and V-type. The screw hole in the middle of the clamp can be used to wear the screw. The installation is very convenient.

Description

Introduction

U clips are used as special connectors for FRP gratings. They are made of stainless steel 201, 304, 316, galvanized, corrosion resistant, and high strength. The shape is divided into M type, U type, and C type according to the purpose. The middle of the clip can be used to wear screws, which is very convenient.

Installation method:

1. U clips:Directly weld the steel grating or stepping plate to the supporting steel structure, and brush the zinc-silver powder paint twice in the welding place.

2. U clips:The special installation clips for the steel gratings of the Yangtze River Delta are used to install, without destroying the galvanized layer, making it easy to disassemble and install. Each set of clamps includes one upper clamp, one lower clamp, one M8 ball screw, and one nut.

3. U clips:According to the need, provide fastening methods such as stainless steel mounting clips or bolt connections.

4. U clips:steel grating installation gap is generally 10MM.

5. U clips:Every installation must pay attention to the firmness and reliability of the installation. It should be checked frequently to prevent loosening of the mounting clamps. Welding of the steel grille close to the vibration source or adding rubber mats.

Q1: How do you ensure the quality of FRP products?

A: All products are manufactured in our own factory under strict ISO-based quality control. We perform raw material testing, process monitoring, and final inspection to ensure every panel meets strength, durability, and corrosion-resistance requirements.

Q2: Where can FRP products be used?

FRP products are ideal for chemical plants, wastewater facilities, offshore platforms, walkways, platforms, stairs, and other areas that require corrosion resistance, lightweight structure, and long service life.

Q3: Do you provide after-sales support?

Yes. We provide clear documentation, installation guidelines (if needed), and technical support. If any quality issue is confirmed after delivery, we offer replacement, rework, or other agreed solutions.

Q4: Can you help with project-specific requirements?

Absolutely. Our team can suggest the right resin system, grating type, and surface finish for your application, and provide drawings or design assistance to ensure project success.