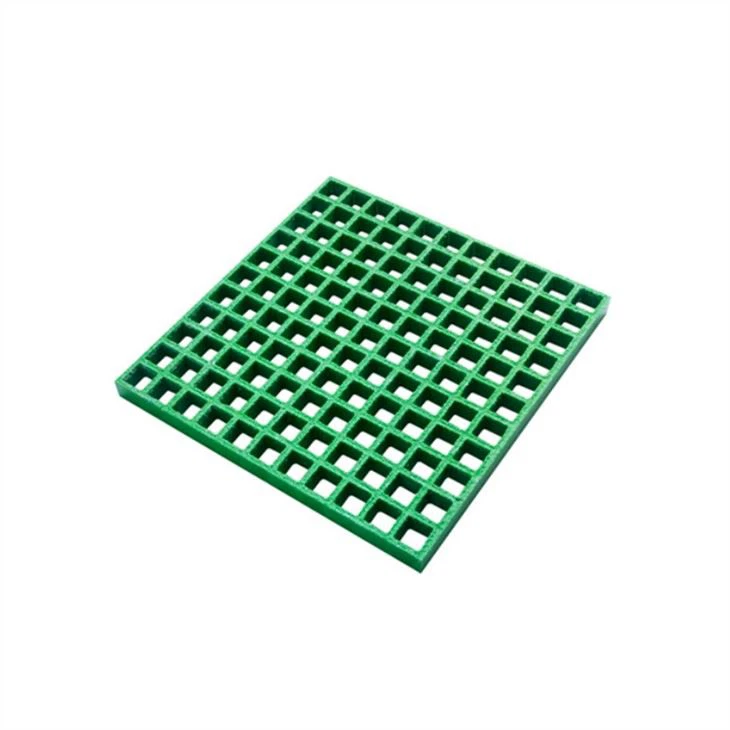

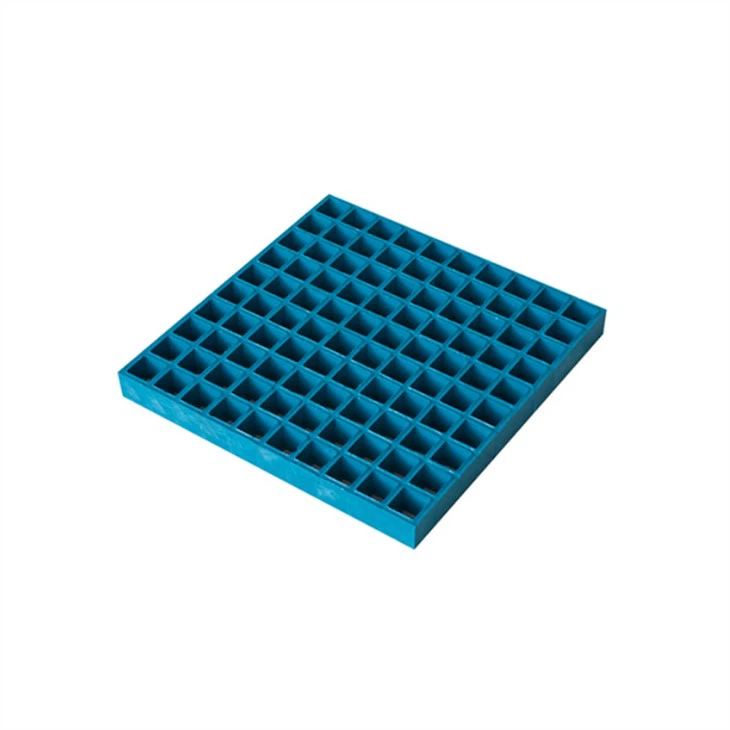

Moulded Fibreglass Grating

Moulded fibreglass grating is used all over the world for a multitude of applications from our factory to your site.

We offer a complete range of moulded gratings to satisfy your various industrial needs and high load requirements.

- Customizable Options – Tailored size, resin type, and surface finish to meet your project needs.

- Factory-Direct Pricing – Save costs with direct production from our source factory.

- Free Sample Design – Get a sample or design validation before bulk production.

- Global Quality Supply – Reliable quality and on-time delivery worldwide.

At present, fibreglass gratings gradually replace the steel gratings in commercial and industrial plants due to advantages over more traditional materials such as the outstanding chemical and mechanical advantages. They are the perfect long-term solution for many industries. Mach’s fibreglass gratings manufactured from various carefully selected resin systems are available in molded grating and pultruded grating. The pultruded fibreglass grating is stiffer and stronger than moulded grating. The moulded fibreglass grating is more flexible, corrosion resistant, and impact resistant than pultruded grating. Furthermore, the moulded fibreglass grating has perfect bi-directional mechanical property, which is one of the reasons why molded gratings are more widely used.

Mach’s moulded fibreglass grating is well-suited for applications where larger open area gratings are required in harsh, highly corrosive environments. So it is the ideal solution for the chemical plant, infrastructure and power sector – they require extensive cutouts for pipe, duct and electrical penetrations.

| Raw Material | Resin + Aluminum Hydroxide + E-Glass |

| Color | Customized color are available, Yellow, green, black, grey, transparent, etc. |

| Specification | Accept customization, see the table below for details |

| Surface Treatment | Grit/concave/flat/with cover |

| Application | Urban construction, chemical industry, power industry, paper industry, Marine exploration, sewage treatment and other industries of the working platform, equipment platform, drilling platform, corridor and so on. |

Unit: mm

| Mesh Size | Height | Load Bar Width(up/down) | Available Panel Size |

| Square Mesh |   Top View  Front View | ||

| 38×38 | 13 | 6.0/5.0 | 1220×4000, 1220×3660, 1220×2440, 915×3050 |

| 15(D) | 6.5/5.0 | 1218×4100 | |

| 20 | 6.0/5.0 | 1220×4000, 1220×3660, 1220×2440, 915×3050 | |

| 25 | 6.4/5.0 | 1220×4000, 1220×3660, 1220×2440, 915×3050 | |

| 30 | 6.5/5.0 | 1220×4000, 1220×3660, 1220×2440, 915×3050 | |

| 38 | 7.0/5.0 | 1220×4000, 1220×3660, 1220×2440, 915×3050 | |

| 30(HLC) | 10.5/9.0 | 1220×3660, 1220×2440, 915×3050 | |

| 35(HLC) | 10.5/9.0 | 1220×3660, 1220×2440, 915×3050 | |

| 50(HLC) | 11.0/9.0 | 1220×4000, 1220×3660, 1220×2440, 915×3050 | |

| 60(HLC) | 11.5/9.0 | 1220×4000, 1220×3660, 1220×2440, 915×3050 | |

| 40×40 | 25 | 7.0/5.0 | 1247×4047, 1007×4047, 1007×3007 |

| 30 | 7.0/5.0 | 1247×4047, 1007×4047, 1007×3007 | |

| 40 | 7.0/5.0 | 1247×4047, 1007×4047, 1007×3007 | |

| 50×50 | 13 | 6.0/5.0 | 1906×4012 |

| 25 | 7.5/6.0 | 1788×4531, 1225×5035 | |

| 40 | 6.8/5.0 | 1220×3660, 1220×2440, 915×3050 | |

| 50 | 7.0/5.0 | 1788×4531 | |

| 50 | 8.0/6.0 | 1800×4000, 1524×4000, 1220×3660, 1220×2440, 915×3050 | |

| 63 | 8.3/6.0 | 1225×4000, 1225×3660, 1225×2440, 915×3050 | |

| 50.8×50.8 | 13 | 7.0/6.0 | 1220×4000, 1220×3660, 1220×2440, 915×3050 |

| 79×79 | 23 | 6.5/5.0 | 405×3569 |

| 83×83 | 25 | 7.0/5.0 | 1007×4007, 1007×3007 |

| 40 | 7.0/5.0 | 1007×4007, 1007×3007 | |

| Mini Mesh |   Top View  Front View | ||

| 12.7×12.7/38×38 | 30 | 7.5&4.5/6.0 | 1220×3660, 1220×2440, 915×3050 (double layer) |

| 19×19/38×38 | 25 | 6.5/5.0 | 1220×4000, 1220×3660, 1220×2440, 915×3050 (double layer) |

| 38 | 7.0/5.0 | 1524×4000, 1220×3660, 1220×2440, 915×3050 (double layer) | |

| 20×20/40×40 | 14 | 7.0/5.0 | 1247×4047, 1007×3007 (double layer) |

| 30 | 7.0/5.0 | 1007×4047, 1007×3007 (double layer) | |

| 40 | 7.0/5.0 | 1007×4047, 1007×3007 (double layer) | |

| 25×25/50×50 | 50 | 8.0/6.0 | 1524×4000 (double layer) |

| 26×26/52×52 | 38 | 6.0/5.0 | 1150×4011 (double layer) |

| Rectangular Mesh |   Top View  Front View | ||

| 25×50 | 38(HLC) | 11.0/9.0 | 1220×3660 |

| 50(HLC) | 12.0/9.0 | 1220×3660 | |

| 25×100 | 25 | 7.0/5.5 | 1007×3007 |

| 25 | 6.5/5.0 | 1220×3660 | |

| 25(HLC) | 9.5/6.0 | 1220×3660, 1220×2440, 915×3050 | |

| 30 | 7.0/5.5 | 1007×3007 | |

| 38 | 8.0/6.0 | 1220×3660 | |

| 38×100 | 38 | 8.0/6.0 | 1220×3660, 1220×2440, 915×3050 |

| 25×152 | 38 | 9.0/6.5 | 1220×3660, 1220×2440, 915×3050 |

| 38×152 | 38 | 8.0/6.0 | 1220×3660, 1220×2440, 915×3050 |

| 60×220 | 40 | 6.3/5.0 | 1788×2238 |

| D=Diamond-type Mesh, HLC=High Load Capacity. |

Q1: How do you ensure the quality of FRP products?

A: All products are manufactured in our own factory under strict ISO-based quality control. We perform raw material testing, process monitoring, and final inspection to ensure every panel meets strength, durability, and corrosion-resistance requirements.

Q2: Where can FRP products be used?

FRP products are ideal for chemical plants, wastewater facilities, offshore platforms, walkways, platforms, stairs, and other areas that require corrosion resistance, lightweight structure, and long service life.

Q3: Do you provide after-sales support?

Yes. We provide clear documentation, installation guidelines (if needed), and technical support. If any quality issue is confirmed after delivery, we offer replacement, rework, or other agreed solutions.

Q4: Can you help with project-specific requirements?

Absolutely. Our team can suggest the right resin system, grating type, and surface finish for your application, and provide drawings or design assistance to ensure project success.

Related Products

相关产品

T-Bar 1 1/2″Deep 40%Open(I15-40)

FRP GratingT-Bar 1″Deep 60%Open(T10-60 ADA)

FRP Grating1/2″ Deep×1 1/2″ Square Mesh

FRP GratingT-Bar 1″Deep 50%Open(T10-50)

FRP Grating1 1/2″ Deep×3/4″ Mini Mesh

FRP GratingT-Bar 1″Deep 50%Open(T10-50)

FRP GratingT-Bar 1″Deep 33%Open(T10-33)

FRP GratingT-Bar 1 1/2″Deep 17%Open(T15-17)

FRP Grating