Molded FRP Grating Isophthalic Resin

Molded FRP grating isophthalic resin is mostly used in the municipal field. It can withstand the environment of medium concentration of inorganic acid and alkali and various salts due to the isophthalic resin has good corrosion resistance. Accept Customized Molded FRP Grating

- Customizable Options – Tailored size, resin type, and surface finish to meet your project needs.

- Factory-Direct Pricing – Save costs with direct production from our source factory.

- Free Sample Design – Get a sample or design validation before bulk production.

- Global Quality Supply – Reliable quality and on-time delivery worldwide.

Molded FRP grating isophthalic resin is more resistant to corrosion than orthophthalic resin grating. The oxygen index of the isophthalic FRP molded grating is 28 or above, and the oxygen index of the isophthalic food-grade FRP molded grating is 26, which is mainly used in meat and food processing plants.

The price is directly proportional to the corrosion resistance, so the resin type should be selected according to the corrosive medium of the application environment. There are three commonly used resin types for FRP molded gratings: Orthophthalic, Isophthalic and Vinyl:

| Code | Resin Type | Standard Color | Application | Price |

| V-CF | Vinyl | Grass, Green, Yellow, Gray, Orange | Chemical use: Excellent corrosion resistance, acid, alkali, salt, solvent resistance, long-term use temperature: -50~110℃ | >Isophthalic, Orthophthalic |

| V-CR | Vinyl | Dark Gray, Black | Used in environment that requires excellent flame retardant and excellent corrosion resistance | |

| I-IF | Isophthalic | Grass Green, Yellow, Gray | Mostly used in the municipal field, good corrosion resistance, can withstand various salts of medium-concentration inorganic acid and alkali, long-term use temperature: -50~90℃ | <Vinyl |

| I-FF | Isophthalic Food Grade | Yellow, Light Grey | Mainly Used In Meat And Food Processing Plants | |

| O-AF | Orthophthalic | Green, Grey, Yellow | General corrosion resistance, resistant to atmospheric aging, seawater corrosion, etc., long-term use temperature: -50~60℃ | <Isophthalic |

| O-AN | Orthophthalic | Grass Green, Yellow, Gray | No Flame Retardant Requirements | <O-AF |

Unit: mm

| |

| Grating Thickness | 13, 14, 15, 20, 25, 30, 35, 38, 40, 50, 63 |

| Mesh Size | 38×38, 40×40, 50×50, 50.8×50.8, 79×79, 83×83, 12.7×12.7/38×38, 19×19/38×38, 20×20/40×40, 25×25/50×50, 26×26/52×52, 25×50, 25×100, 38×100, 25×152, 38×152, 60×220 |

| Available Panel Size | 1220×4000, 1220×3660, 1220×2440, 915×3050, 565×3050, 1218×4000, 1524×4000, 1247×4047, 1007×4047, 1007×3007, 1906×4012, 1788×4531, 1788×2238, 1225×5035, 1800×4000, 1255×4000, 405×3569, 1150×4011, |

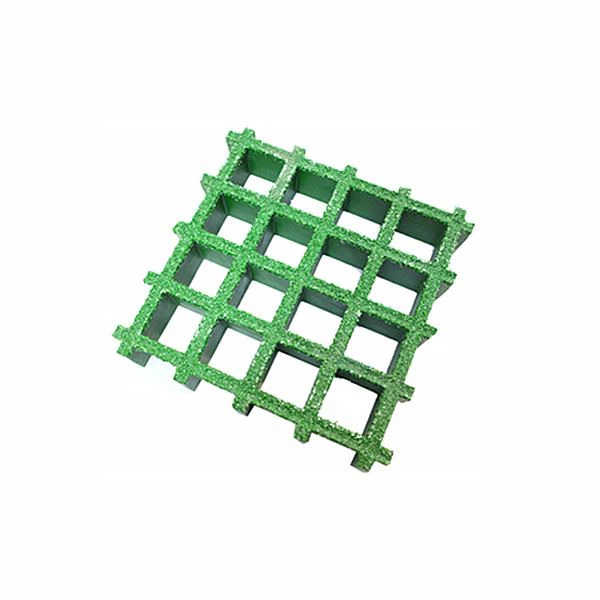

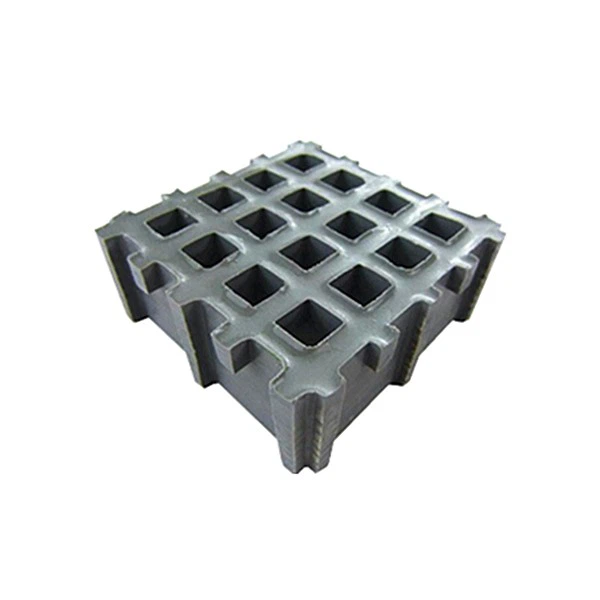

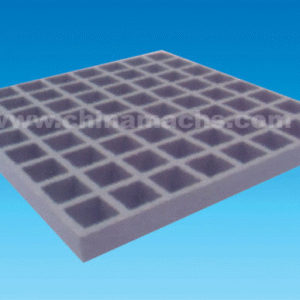

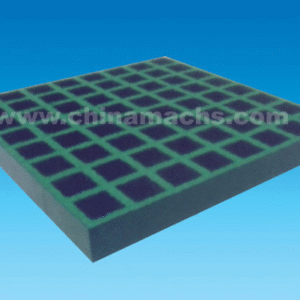

| Surface Treatment | Concave surface, Grit surface, Smooth surface, Covered surface |

| Raw Materials | Resin, Glass fiber roving, Aluminum hydroxide |

| Available Colors | Light grey, Yellow, Grass green |

| Corrosion and Aging Resistance | Good |

◆ Surface Treatment

Concave surface |  Grit surface Grit surface |  Smooth surface Smooth surface |  Covered surface Covered surface |

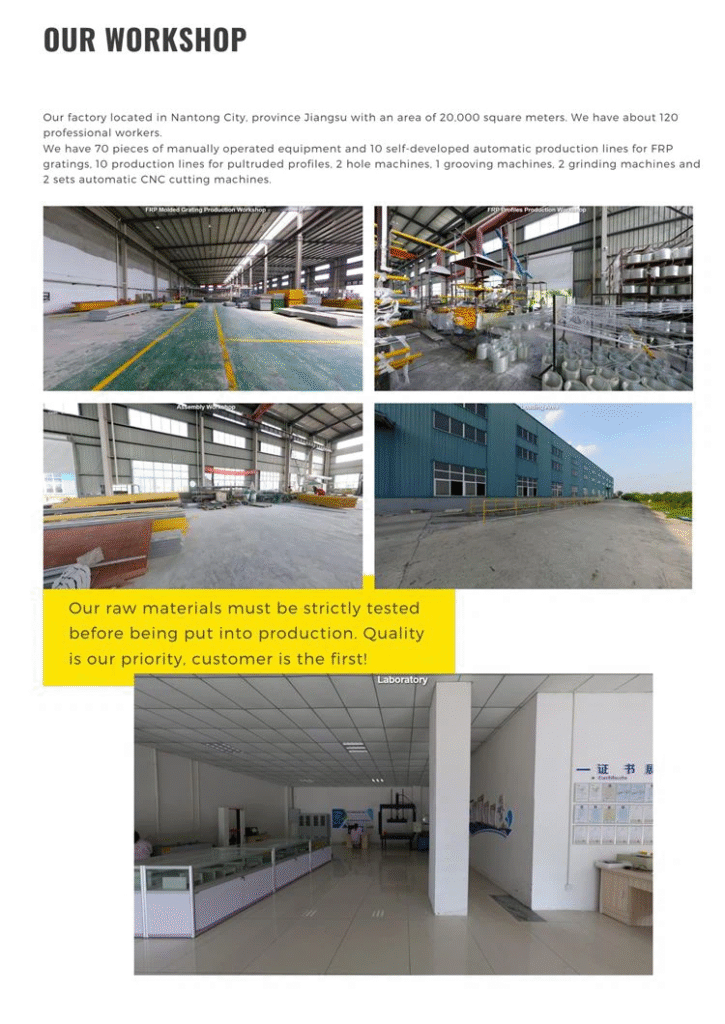

Q1: How do you ensure the quality of FRP products?

A: All products are manufactured in our own factory under strict ISO-based quality control. We perform raw material testing, process monitoring, and final inspection to ensure every panel meets strength, durability, and corrosion-resistance requirements.

Q2: Where can FRP products be used?

FRP products are ideal for chemical plants, wastewater facilities, offshore platforms, walkways, platforms, stairs, and other areas that require corrosion resistance, lightweight structure, and long service life.

Q3: Do you provide after-sales support?

Yes. We provide clear documentation, installation guidelines (if needed), and technical support. If any quality issue is confirmed after delivery, we offer replacement, rework, or other agreed solutions.

Q4: Can you help with project-specific requirements?

Absolutely. Our team can suggest the right resin system, grating type, and surface finish for your application, and provide drawings or design assistance to ensure project success.

Related Products

相关产品

1 1/4″ Deep×1 1/2″ Square Mesh

FRP GratingT-Bar 1″Deep 35%Open(T10-35)

FRP Grating1 1/2″ Deep×1 1/2″ Square Mesh

FRP GratingT-Bar 1″Deep 33%Open(T10-33)

FRP GratingT-Bar 1″Deep 40%Open(T10-40)

FRP Grating1″ Deep×1 1/2″ Square Mesh

FRP Grating2″ Deep×2″ Square Mesh

FRP GratingT-Bar 1 1/2″Deep 50%Open(I15-50)

FRP Grating