M Clips for Grating installation

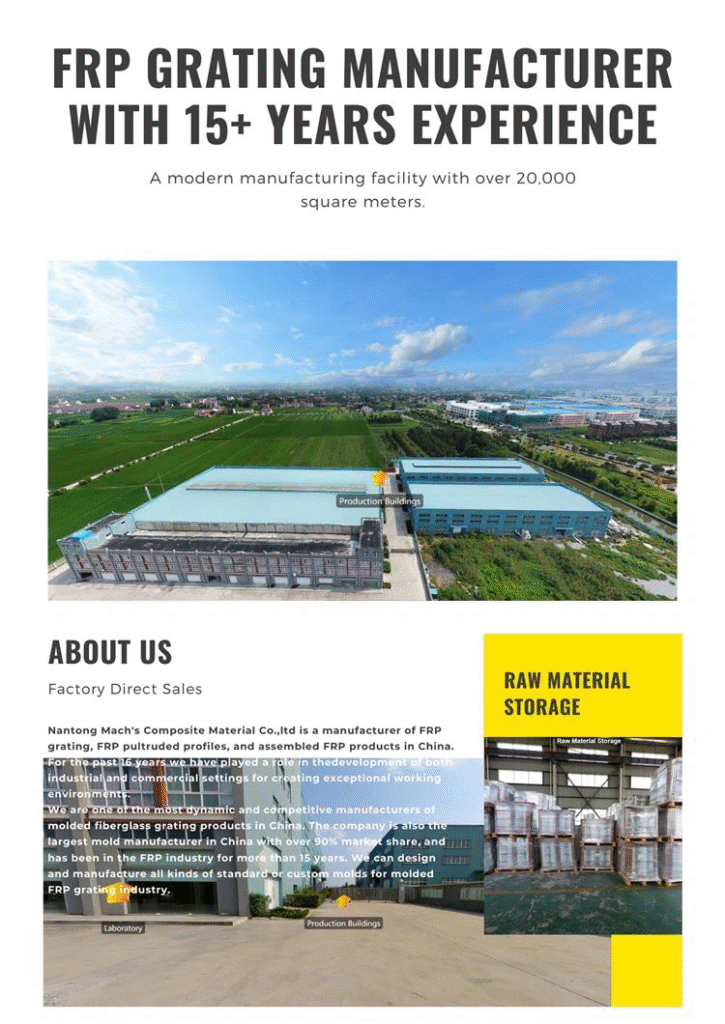

- Customizable Options – Tailored size, resin type, and surface finish to meet your project needs.

- Factory-Direct Pricing – Save costs with direct production from our source factory.

- Free Sample Design – Get a sample or design validation before bulk production.

- Global Quality Supply – Reliable quality and on-time delivery worldwide.

316L or 304L STAINLESS STEEL CLIPS FOR THE FRP GRATINGS, M TYPE. G TYPE AND L TYPE. ALL KIND OF CLIPS AVAILABLE HERE!

M Clips/clamp

Type:316/304SS or other material

Dimension:Deep 25mm,38mm,50mm, (1″ 1.5″ 2″)

Production details : M clips or saddle clips clamp 2 fiberglass grating load bars to the support. This provides excellent holding capability and because of this, are recommended for stair treads and most molded and pultruded fiberglass gratings. If you want to customize the clips or fasteners, you just provide samples or CAD drawings and we will make new die for free, there is no limit on clips or fasteners quantity.Also we can provide the CAD, 3D & PDF for you.we also according you provide the clip/clamp samples or fasteners to make.If you are interested, contact with us please, and we promise will give you approving answer.

1) The clip apply to all kinds of gratings, it is made of the M8 bolt, top clip and bottom clip.

2) The method of clip fixing: There are at least 4 clips on every piece of FRP grating, about the big span FRP grating it is better to use more clips.

3) Stainless Steel M clips FRP Molded Grating Used Metal Saddle Clips

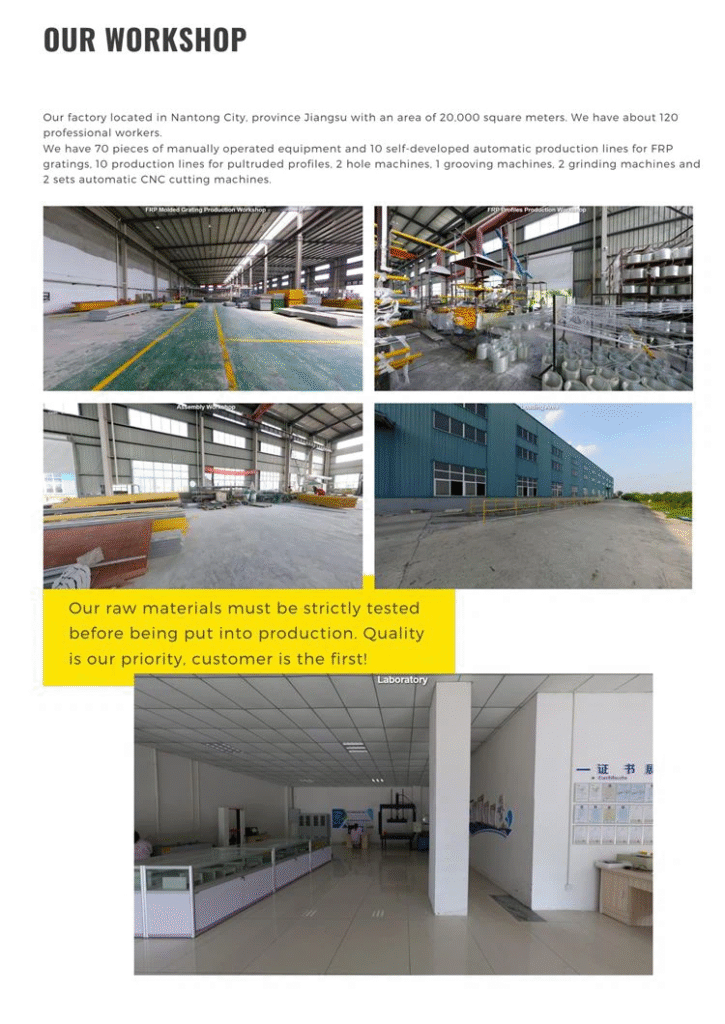

Popular grating accessories are available from Nantong Machs’. No grating job is complete without the necessary clips, plates, bolts and seats. We carry specialized accessories for our bar grating.

“M” Clips hold two bars and can be used to snug the grating to the support. Due to the extra holding capabilities, these are specifically recommended for stair treads. Stair treads should have a minimum of four clips on each tread.

4) According to the client’s requests, we can supply stainless steel clips.

5) application:

flooring steel gratings

stair treads

sun shades

drain covers

security screen

manhole covers

mezzanine flooring

earth mats

shelving

Stanchions (hand rails)

Q1: How do you ensure the quality of FRP products?

A: All products are manufactured in our own factory under strict ISO-based quality control. We perform raw material testing, process monitoring, and final inspection to ensure every panel meets strength, durability, and corrosion-resistance requirements.

Q2: Where can FRP products be used?

FRP products are ideal for chemical plants, wastewater facilities, offshore platforms, walkways, platforms, stairs, and other areas that require corrosion resistance, lightweight structure, and long service life.

Q3: Do you provide after-sales support?

Yes. We provide clear documentation, installation guidelines (if needed), and technical support. If any quality issue is confirmed after delivery, we offer replacement, rework, or other agreed solutions.

Q4: Can you help with project-specific requirements?

Absolutely. Our team can suggest the right resin system, grating type, and surface finish for your application, and provide drawings or design assistance to ensure project success.

Related Products

相关产品

U Clamp

Grating ClipsG Clips For FRP Grating

Grating ClipsAccessories For Gratings Made Out Of SS Steel

Grating ClipsFRP Grating C Clips 38x38mm

Grating ClipsC Clamp

Grating ClipsClamp Fastener

Grating ClipsL Clip

Grating ClipsJ Clips

Grating Clips