GRP Pultruded Grating

GRP pultruded grating is composed of a series of GRP pultruded profiles, which is mainly used for decoration building materials or industrial equipment.

Accept Customized Service

A Choice of RAL Colors Available

- Customizable Options – Tailored size, resin type, and surface finish to meet your project needs.

- Factory-Direct Pricing – Save costs with direct production from our source factory.

- Free Sample Design – Get a sample or design validation before bulk production.

- Global Quality Supply – Reliable quality and on-time delivery worldwide.

GRP pultruded grating has 2~3 times of strength as molded grating, which is applied to applications requiring large load-bearing capacity and wide span. The resin content of GRP pultruded grating accounts for about 35%, while the glass fiber accounts for about 65%, ensuring that the strength and hardness are twice as much as the molded gratings.

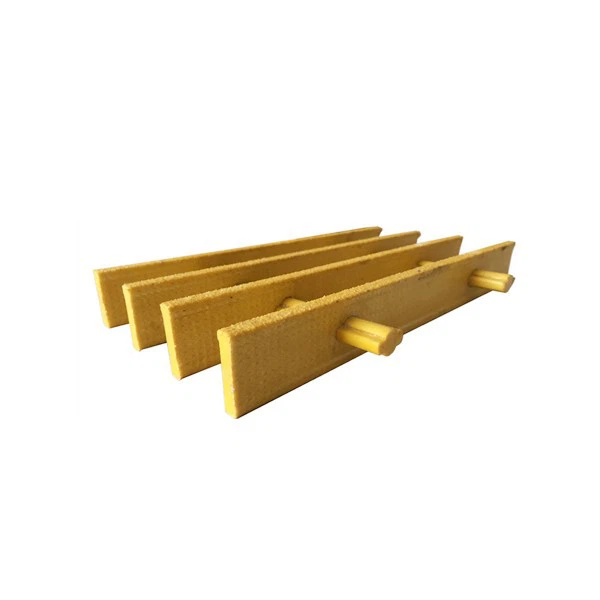

GRP pultruded grating is composed of pultruded “I” profile or “T” profile, and various pultruded rods or special-shaped rods as cross bars, which are fixedly connected together at a certain distance through adhesive:

1.Load-bearing profile: mainly composed of pultruded “I” bar or “T” bar.

2.Connecting profile: the function is to connect load-bearing profiles, including pultruded round rods or pultruded special-shaped rods.

GRP pultruded grating can be used for trench cover, grating walkway, power fence, packing bracket, substation cobblestone layer support, etc. due to high strength, longer span and long service life.

◆ Common size of Mach’s GRP pultruded grating

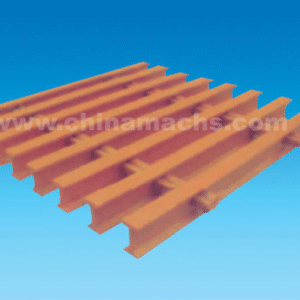

▽ I bar GRP pultruded grating

| Model No. | Grating Thickness | Pultrusion Beam Size(top/bottom) | Open Area | Weight | |

| CD pin | three-core pin | ||||

| I4010 | 25 | 15/15 | 40% | 15.60kg/m2 | 17.10kg/m2 |

| I5010 | 25 | 15/15 | 50% | 12.70kg/m2 | 14.20kg/m2 |

| I6010 | 25 | 15/15 | 60% | 9.70kg/m2 | 11.20kg/m2 |

| I40125 | 32 | 15/15 | 40% | 18.33kg/m2 | 19.83kg/m2 |

| I50125 | 32 | 15/15 | 50% | 15.90kg/m2 | 17.40kg/m2 |

| I60125 | 32 | 15/15 | 60% | 12.00kg/m2 | 13.50kg/m2 |

| 14015 | 38 | 15/15 | 40% | 21.01kg/m2 | 22.01kg/m2 |

| I5015 | 38 | 15/15 | 50% | 18.10kg/m2 | 19.10kg/m2 |

| I6015 | 38 | 15/15 | 60% | 15.50kg/m2 | 16.10kg/m2 |

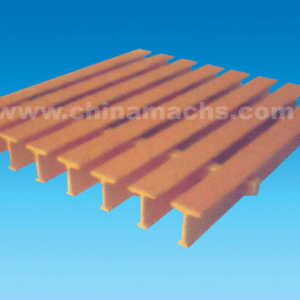

▽ T bar GRP pultruded grating

Unit: mm

Unit: mm

| Model No. | Grating Thickness | Pultrusion Beam Size(top/bottom) | Open Area | Weight |

| three-core pin | ||||

| T1210 | 25 | 38/15 | 12% | 14.50kg/m2 |

| T1810 | 25 | 41.3/15 | 18% | 13.80kg/m2 |

| T2510 | 25 | 38/15 | 25% | 12.30kg/m2 |

| T3310 | 25 | 41.3/15 | 33% | 11.20kg/m2 |

| T3810 | 25 | 38/15 | 38% | 10.20kg/m2 |

| T1215 | 38 | 38/15 | 12% | 19.60kg/m2 |

| T2515 | 38 | 38/15 | 25% | 16.70kg/m2 |

| T3815 | 38 | 38/15 | 38% | 14.20kg/m2 |

| T5015 | 38 | 25/15 | 50% | 10.30kg/m2 |

| T3320 | 50 | 25/15 | 33% | 20.27kg/m2 |

| T5020 | 50 | 25/15 | 50% | 15.66kg/m2 |

▽ High-load GRP pultruded grating

Unit: mm

Unit: mm

| Model No. | Grating Thickness | Pultrusion Beam Size(top/bottom) | Open Area | Weight |

| three-core pin | ||||

| HL4020 | 50 | 15 | 40% | 70.37kg/m2 |

| HL5020 | 50 | 15 | 50% | 52.24kg/m2 |

| HL6020 | 50 | 15 | 60% | 43.50kg/m2 |

Corrosion Resistance Table of GRP Pultruded Grating

Unit: mm

| Chemical medium | Vinyl | Isophthalic | ||

| Concentration(%) | Maximum temperature resistance(℃) | Concentration(%) | Maximum temperature resistance(℃) | |

| Acetic acid | 50 | 180/82 | 50 | 125/52 |

| Benzoic acid | Saturated solution | 200/93 | Saturated solution | 150/66 |

| Chromic acid | 10 | 120/49 | 5 | 70/21 |

| Citric acid | Concentrate | 200/93 | Concentrate | 170/77 |

| Hydrobromic acid | 50 | 120/49 | 50 | 120/49 |

| Hydrochloric acid | 37 | 100/38 | 37 | 75/24 |

| Lactic acid | Concentrate | 200/93 | Concentrate | 170/77 |

| Nitric acid | 20 | 100/38 | 20 | 70/21 |

| Oxalic acid | Concentrate | 120/96 | Concentrate | 75/24 |

| Perchloric acid | 30 | 80/27 | Not recommended | Not recommended |

| Phosphoric acid | 100 | 200/93 | 100 | 120/49 |

| Sulfuric acid | 75 | 100/38 | 25 | 75/24 |

| Tartaric acid | Concentrate | 200/93 | Concentrate | 170/77 |

| Vinegar | 100 | 200/93 | 100 | 170/77 |

| Ammonium hydroxide | 28 | 100/38 | 28 | Not recommended |

| Aluminum hydroxide | 100 | 170/77 | 100 | 160/71 |

| Borax | Saturated solution | 200/93 | Saturated solution | 170/77 |

| Amine oxide | Concentrate | 190/88 | Concentrate | 170/77 |

| Ammonium Bicarbonate | 50 | 150/65 | 15 | 125/52 |

| Ammonium Sulfate | Concentrate | 200/93 | Concentrate | 170/77 |

| Calcium carbonate | Concentrate | 180/82 | Saturated solution | 170/77 |

| Calcium nitrate | Concentrate | 200/93 | Concentrate | 180/82 |

| Copper chloride | Concentrate | 200/93 | Concentrate | 170/77 |

| Copper cyanide | Concentrate | 200/93 | Concentrate | 170/77 |

| Copper nitrate | Concentrate | 200/93 | Concentrate | 170/77 |

| Ferric chloride | Concentrate | 200/93 | Concentrate | 170/77 |

| Ferrous chloride | Concentrate | 200/93 | Concentrate | 170/77 |

| Lithium chloride | Saturated solution | 200/93 | Saturated solution | 150/66 |

| Magnesium chloride | Concentrate | 200/93 | Concentrate | 170/77 |

| Magnesium nitrate | Concentrate | 180/82 | Concentrate | 140/66 |

| Magnesium sulfate | Concentrate | 190/88 | Concentrate | 170/77 |

| Mercury chloride | 100 | 190/88 | 100 | 150/56 |

| Mercurous chloride | Concentrate | 180/82 | Concentrate | 140/60 |

| Nickel chloride | Concentrate | 200/93 | Concentrate | 170/77 |

| Nickel sulfate | Concentrate | 200/93 | Concentrate | 170/77 |

| Potassium chloride | Concentrate | 200/93 | Concentrate | 170/77 |

| Potassium dichromate | Concentrate | 200/93 | Concentrate | 170/77 |

| Potassium nitrate | Concentrate | 200/93 | Concentrate | 170/77 |

| Potassium sulfate | Concentrate | 200/93 | Concentrate | 170/77 |

| Sodium acetate | Concentrate | 300/93 | Concentrate | 160/71 |

| Sodium bisulfate | Concentrate | 200/93 | Concentrate | 170/77 |

| Sodium bromide | Concentrate | 200/93 | Concentrate | 170/77 |

| Sodium chloride | Concentrate | 200/93 | Concentrate | 170/77 |

| Sodium cyanide | 25 | 150/66 | Not recommended | Not recommended |

| Sodium nitrate | Concentrate | 200/93 | Concentrate | 170/77 |

| Sodium sulfate | Concentrate | 200/93 | Concentrate | 170/77 |

| Tin chloride | Concentrate | 190/88 | Concentrate | 160/71 |

| Zinc nitrate | Concentrate | 200/93 | Concentrate | 170/77 |

| Carbon tetrachloride | 100 | 75/24 | Not recommended | Not recommended |

| Chlorine | – | 170/77 | – | 140/60 |

| Chlorine water | Saturated solution | 180/82 | Saturated solution | 80/27 |

| Ethanol | 50 | 90/32 | 50 | 75/24 |

| Vinyl glycol | 100 | 200/93 | 100 | 90/32 |

| Formaldehyde | Concentrate | 100/38 | 50 | 75/24 |

| Gasoline | 100 | 150/65 | 100 | 80/27 |

| Glucose | 100 | 200/93 | 100 | 170/77 |

| Glycerin | 100 | 200/93 | 100 | 150/66 |

| Hydrogen peroxide | 30 | 100/38 | 5 | 100/38 |

| Propylene glycol | Concentrate | 200/93 | Concentrate | 170/77 |

| Distilled water | 100 | 180/82 | 100 | 170/77 |

| Benzene | Not recommended | Not recommended | Not recommended | Not recommended |

Q1: How do you ensure the quality of FRP products?

A: All products are manufactured in our own factory under strict ISO-based quality control. We perform raw material testing, process monitoring, and final inspection to ensure every panel meets strength, durability, and corrosion-resistance requirements.

Q2: Where can FRP products be used?

FRP products are ideal for chemical plants, wastewater facilities, offshore platforms, walkways, platforms, stairs, and other areas that require corrosion resistance, lightweight structure, and long service life.

Q3: Do you provide after-sales support?

Yes. We provide clear documentation, installation guidelines (if needed), and technical support. If any quality issue is confirmed after delivery, we offer replacement, rework, or other agreed solutions.

Q4: Can you help with project-specific requirements?

Absolutely. Our team can suggest the right resin system, grating type, and surface finish for your application, and provide drawings or design assistance to ensure project success.

Related Products

相关产品

T-Bar 1″Deep 50%Open(T10-50)

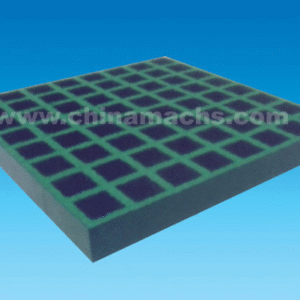

FRP Grating30mm Deep×20mm Mini Mesh

FRP Grating2″ Deep×2″ Square Mesh

FRP Grating1 1/2″ Deep×1 1/2″ Square Mesh

FRP GratingT-Bar 1 1/2″Deep 33%Open(T15-33)

FRP Grating1 1/2″ Deep×3/4″ Mini Mesh

FRP GratingT-Bar 1/4″Deep 40%Open(I12-40)

FRP GratingT-Bar 1″Deep 18%Open(T10-18)

FRP Grating