Fiberglass Pultruded Grating

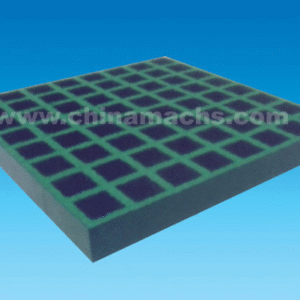

Fiberglass pultruded grating is the perfect complement to the application of fiberglass molded grating.

Accept Customized Service

A Choice of RAL Colors Available

- Customizable Options – Tailored size, resin type, and surface finish to meet your project needs.

- Factory-Direct Pricing – Save costs with direct production from our source factory.

- Free Sample Design – Get a sample or design validation before bulk production.

- Global Quality Supply – Reliable quality and on-time delivery worldwide.

Fiberglass pultruded grating has most of the characteristics of the fiberglass molded grating. Its application is basically the same as that of the fiberglass molded grating(usually used for waterfront or high-altitude plank road). However, there are also significant differences, the most important one is the fiberglass content (65-70%) in the direction of the load-bearing bar, so it is more advantageous to use over long spans than the fiberglass molded grating. Moreover, it will reduce the foundation support and reduce engineering costs.

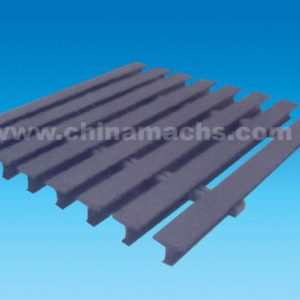

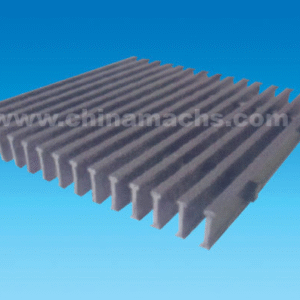

Three types profiles are required for the fiberglass pultruded grating to be used as load-bearing, spacing and transverse connecting elements respectively. Common section shapes of load-bearing elements are type I and type T. Theoretically, the load-bearing elements are mainly subjected to bending load, while the bending section coefficient of type I is larger with the same section area.

◆ Fiberglass pultruded grating resin system

Unit: mm

| Code Name | Resin Matrix | Corrosion Resistance | Application |

| VE | Vinyl | Excellent | Under severely corrosive environments such as acids, alkalis, and solvents |

| ISO | Isophthalic | Good | Excellent acid resistance, moderate alkali and solvent resistance |

| ORTHO | Orthophthalic | General | General acid and alkali environment |

◆ Fiberglass pultruded grating specifications

The cross bar spacing can be changed as required to produce varying hole spacing. You can choose the position of the connecting rod, the size, shape, color and surface form of the load bar as required(areas with oil stains, the grit surface can be selected to prevent slip).

Unit: mm

| Model No. | Thickness | Hole Spacing | Open Area | Weight(kg/m2) |

| I | 25 | 10, 15, 23 | 40%, 50%, 60% | 17.1, 14.2, 11.2 |

| I | 32 | 10, 15, 23 | 40%, 50%, 60% | 19.83, 17.4, 13.5 |

| I | 38 | 10, 15, 23 | 40%, 50%, 60% | 22.0, 19.1, 16.1 |

| T | 25 | 13、23 | 33%,38% | 12.2, 11.2 |

| T | 38 | 13、25 | 33%,50% | 19.5, 15.1 |

◆ Fiberglass pultruded grating surface treatment

Smooth Surface Smooth Surface |  Grit Surface Grit Surface |  Non-slip Groove Surface Non-slip Groove Surface |  Covered Surface Covered Surface |

Q1: How do you ensure the quality of FRP products?

A: All products are manufactured in our own factory under strict ISO-based quality control. We perform raw material testing, process monitoring, and final inspection to ensure every panel meets strength, durability, and corrosion-resistance requirements.

Q2: Where can FRP products be used?

FRP products are ideal for chemical plants, wastewater facilities, offshore platforms, walkways, platforms, stairs, and other areas that require corrosion resistance, lightweight structure, and long service life.

Q3: Do you provide after-sales support?

Yes. We provide clear documentation, installation guidelines (if needed), and technical support. If any quality issue is confirmed after delivery, we offer replacement, rework, or other agreed solutions.

Q4: Can you help with project-specific requirements?

Absolutely. Our team can suggest the right resin system, grating type, and surface finish for your application, and provide drawings or design assistance to ensure project success.

Related Products

相关产品

T-Bar 1 1/2″Deep 40%Open(I15-40)

FRP Grating1 1/2″ Deep×1″×6″ SuperSpan

FRP Grating2″ Deep×2″ Square Mesh

FRP GratingT-Bar 1″Deep 33%Open(T10-33)

FRP GratingT-Bar 1 1/2″Deep 60%Open(IP15-60 ADA)

FRP GratingT-Bar 1″Deep 60%Open(T10-60 ADA)

FRP Grating30mm Deep×20mm Mini Mesh

FRP Grating1 1/2″ Deep×1 1/2″ Square Mesh

FRP Grating