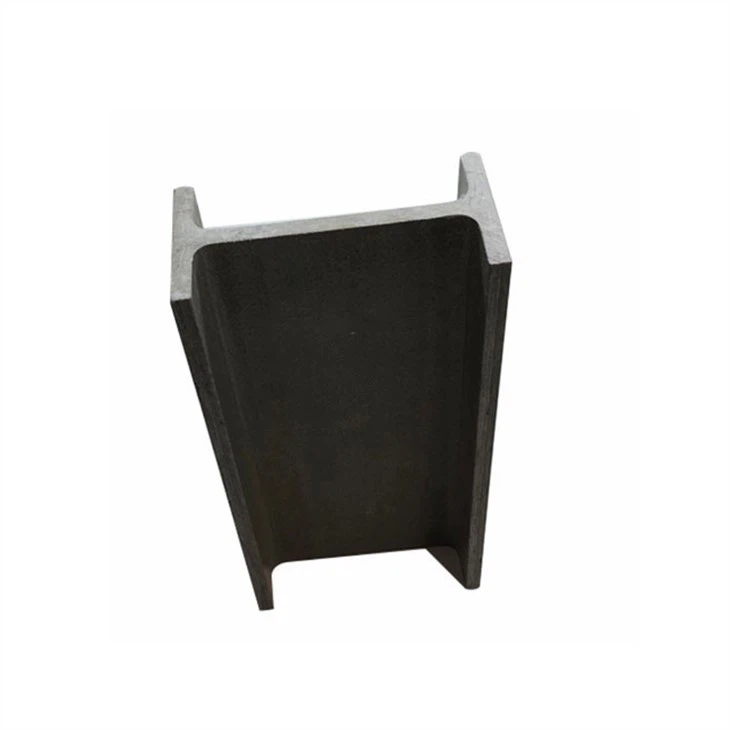

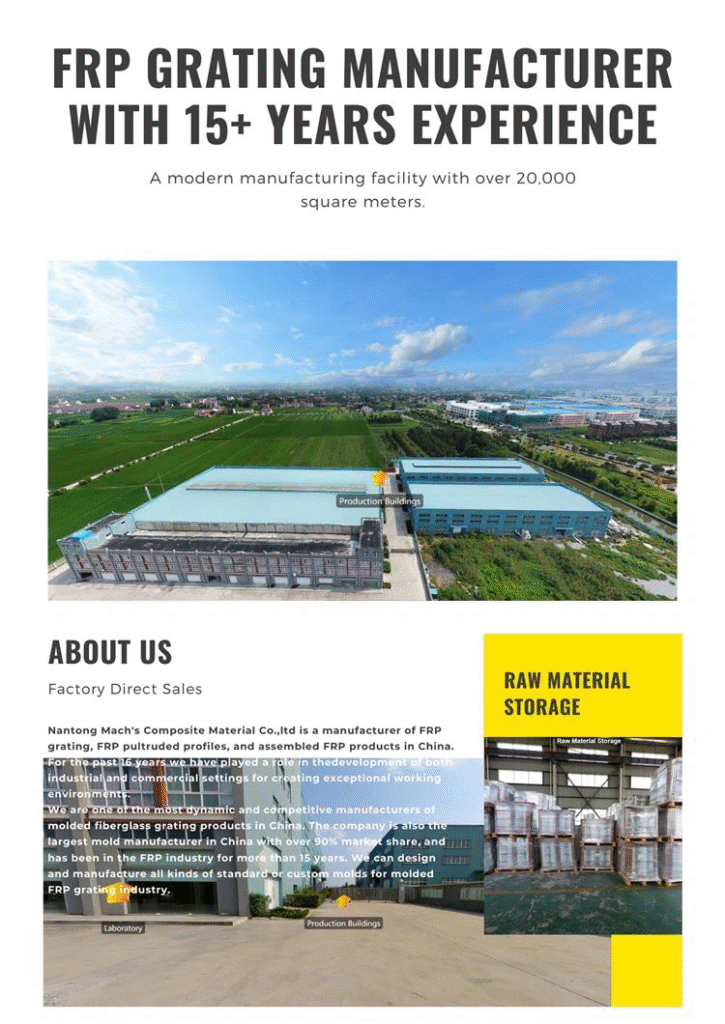

Fiberglass I Beams

Fiberglass i beams offer the strength of steel at a fraction of the weight and can withstand harsh corrosive environments.

Mach’s Composites Structural Products are available in different resin materials, each formulated to satisfy special project requirements.

- Customizable Options – Tailored size, resin type, and surface finish to meet your project needs.

- Factory-Direct Pricing – Save costs with direct production from our source factory.

- Free Sample Design – Get a sample or design validation before bulk production.

- Global Quality Supply – Reliable quality and on-time delivery worldwide.

Steel i beams are often used as support structures of buildings, industrial facilities, and platforms. However, corrosion is a ubiquitous problem that can jeopardize the structural integrity of steel i beams when they are exposed to high humidity, outdoor environments or chemicals (acids, alkalis). These corroded beams will gradually become fragile over time, increasing the risk factor.

We have seen more and more engineers and builders gravitate towards fiberglass i beams that are manufactured by pultrusion and special production process with resin and E-glass. Mach’s fiberglass i beam is a unique and innovative alternative to timber, concrete, aluminum and steel i beams because fiberglass profiles have superior resistance to high corrosion. At the same time, fiberglass i beam is lightweight enough to add virtually no dead load to the structure, so it is a good replacement to steel and other materials in harsh environments engineering.

Mach’s Composites is dedicated to providing customers with all types of structural profiles, which are available in different resin materials, each formulated to satisfy special project requirements.

| Material composition | Resin + E-Glass + Filler |

| Resin Type | VE/ISO/ORTHO |

| Color | Grey or any other color selected from the RAL |

| Shape | “Ⅰ” Shape |

| Application | Support Structures of Bridges, Buildings, Industrial facilities, Platforms, etc. |

| Certification | ISO14001, ISO9001, SGS |

| Trade Terms | EXW FOB CNF CIF |

| Shipping Way | By sea /air/express |

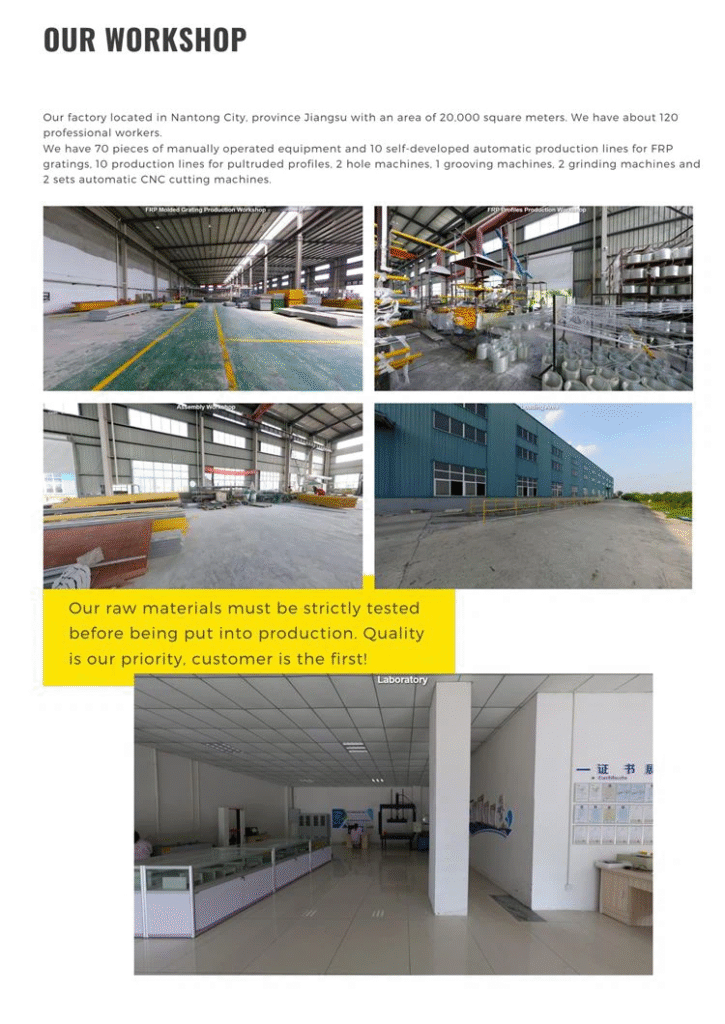

Unit: mm

| Product Sectional View | Flange Width (b) | Depth (d) | Thickness 1 (t1) | Thickness 2 (t2) | Weight (kg/m) |

| 15 | 25 | 4.0 | 6.4 | 0.40 |

| 15 | 32 | 4.0 | 6.4 | 0.44 | |

| 15 | 38 | 4.0 | 6.4 | 0.51 | |

| 38 | 76 | 6.4 | 6.4 | 1.69 | |

| 50 | 102 | 6.4 | 6.4 | 2.40 | |

| 76 | 152 | 6.4 | 6.4 | 3.59 | |

| 76 | 203 | 9.5 | 9.5 | 5.32 | |

| 102 | 203 | 9.5 | 9.5 | 7.20 | |

| 102 | 254 | 12.7 | 12.7 | 9.50 | |

| 127 | 254 | 9.5 | 9.5 | 9.00 | |

| 127 | 254 | 12.7 | 12.7 | 11.90 | |

| 152 | 305 | 9.5 | 9.5 | 10.74 | |

| 152 | 305 | 12.7 | 12.7 | 14.30 |

| Accept customized services, sizes can be customized upon your specific requirements. |

Q1: How do you ensure the quality of FRP products?

A: All products are manufactured in our own factory under strict ISO-based quality control. We perform raw material testing, process monitoring, and final inspection to ensure every panel meets strength, durability, and corrosion-resistance requirements.

Q2: Where can FRP products be used?

FRP products are ideal for chemical plants, wastewater facilities, offshore platforms, walkways, platforms, stairs, and other areas that require corrosion resistance, lightweight structure, and long service life.

Q3: Do you provide after-sales support?

Yes. We provide clear documentation, installation guidelines (if needed), and technical support. If any quality issue is confirmed after delivery, we offer replacement, rework, or other agreed solutions.

Q4: Can you help with project-specific requirements?

Absolutely. Our team can suggest the right resin system, grating type, and surface finish for your application, and provide drawings or design assistance to ensure project success.

Related Products

相关产品

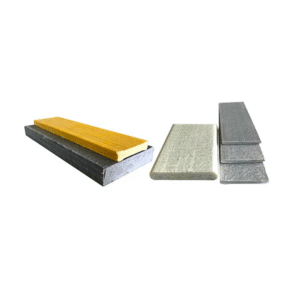

Flat、Article flat

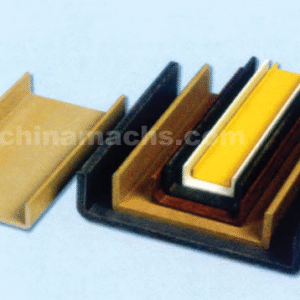

FRP ProfilesAngle steel

FRP ProfilesFiberglass Angle Iron

FRP ProfilesSquare Fiberglass Rod

FRP ProfilesFiberglass Flat Rods

FRP ProfilesChannel steel

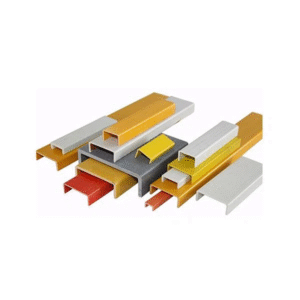

FRP ProfilesH beams

FRP ProfilesFRP C Channel

FRP Profiles