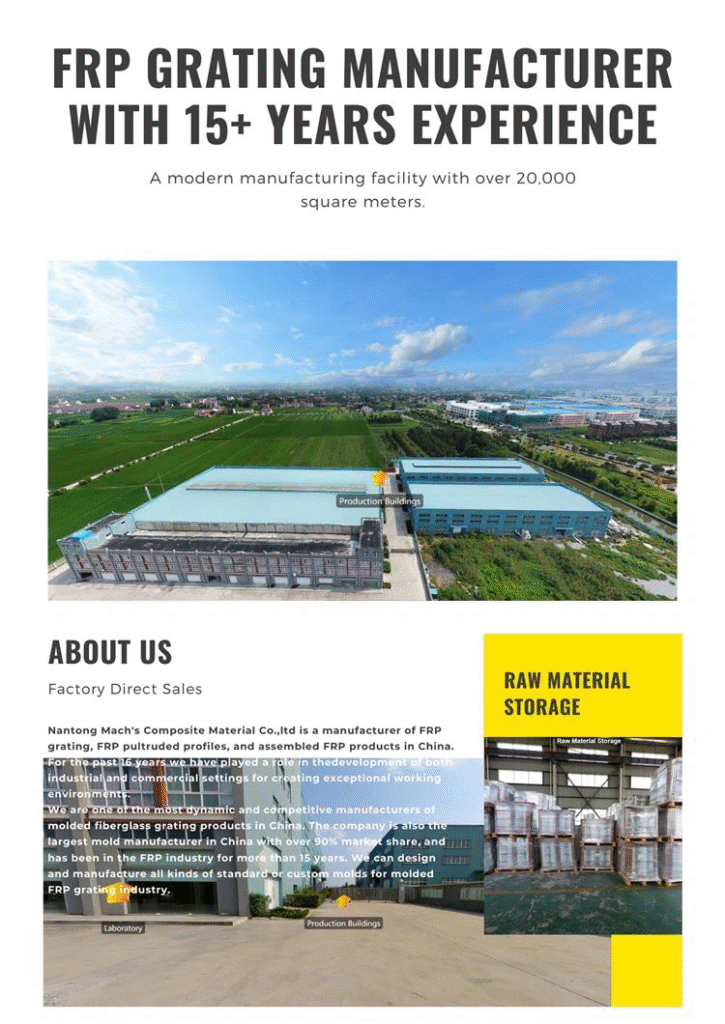

Fiberglass Grid Grating

Fiberglass grid grating has superior chemical resistance, which is often used in heavy industry, such as oil and gas, factories, water treatment and other highly corrosive industries.

We supply full panel as well as custom size as per client requirement.

- Customizable Options – Tailored size, resin type, and surface finish to meet your project needs.

- Factory-Direct Pricing – Save costs with direct production from our source factory.

- Free Sample Design – Get a sample or design validation before bulk production.

- Global Quality Supply – Reliable quality and on-time delivery worldwide.

As is known to us all, besides high installation cost, steel and aluminum grating get corrode, wear down quickly, come unassembled, and are unattractive, which lead to maintenance headaches and downtimes. Fiberglass grating has been tested and proven that it is an effective alternative to steel and aluminum grating that exposure to corrosive environments or other types of gratings need frequent replacements.

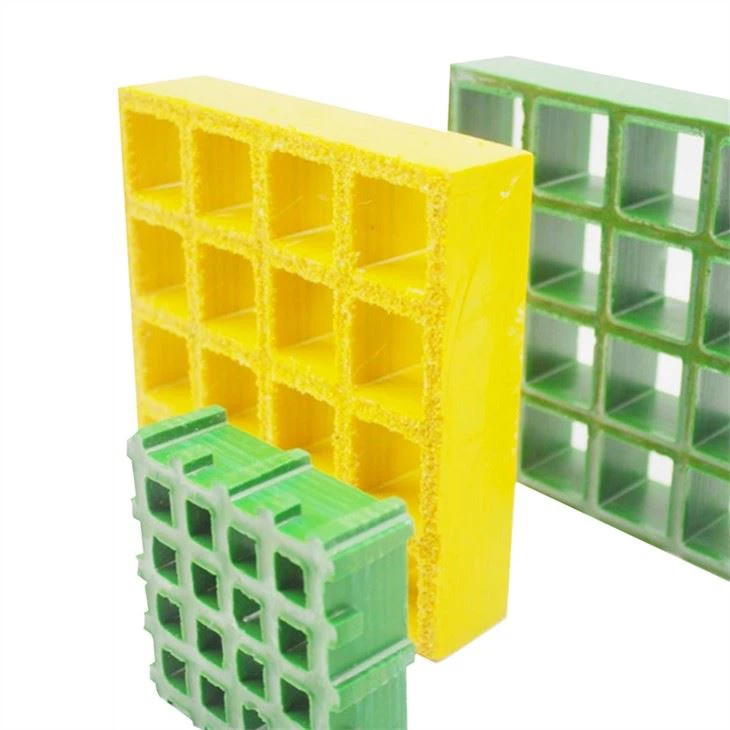

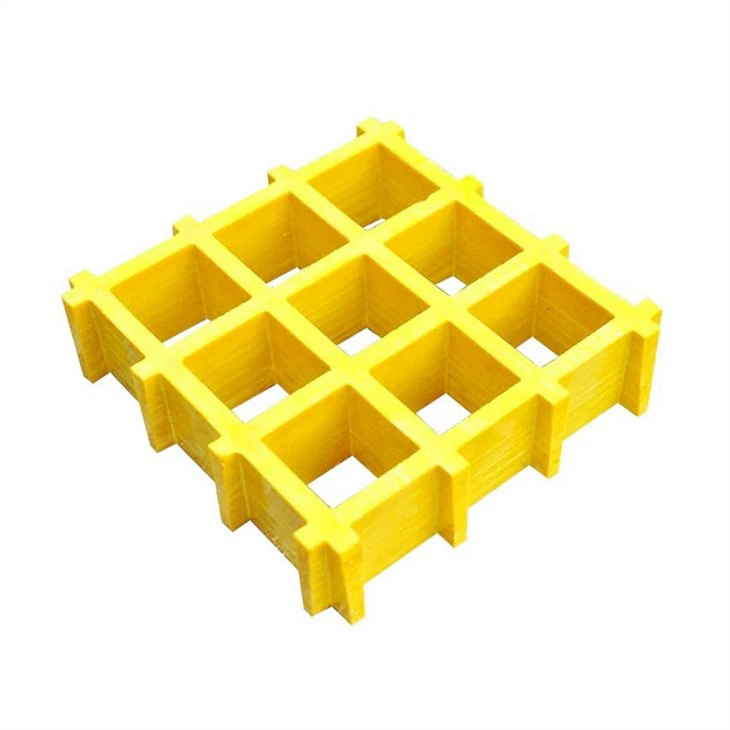

When it comes to highly corrosive applications, extremely excellent corrosion and rust resistance are the best representatives of molded fiberglass grating. Molded fiberglass grating with square or rectangular grid patterns, namely fiberglass grid grating, is ideally suited for highly corrosive applications where larger open area gratings are required, such as wastewater and sewage treatment plants.

Mach’s fiberglass grid grating is the preferred choice of some heavy industries, which can be cut in any shape, size at site easily. We also supply different grating height for various load capacity, and full panel as well as custom size as per client requirement.

| Raw Material | Resin + Aluminum Hydroxide + E-Glass |    |

| Resin System | Vinyl Ester/Isophthalic/Orthophthalic | |

| Grating Height | 13mm, 14mm, 15mm, 20mm, 23mm, 25mm, 30mm, 35mm, 38mm, 40mm, 50mm, 63mm | |

| Grid Size | SM 38×38, SM 40×40, SM 50×50, SM 79×79, SM 83×83 SM 38(12.7×12.7), SM 38(19×19), SM 40(20×20), SM 50(25×25), SM 52(26×26) RM 25×50, RM 25×100, 38×100, RM 25×152, RM 38×152, RM 60×220 | |

| Panel Size | 1220×4000, 1220×3660, 1220×2440, 915×3050, 1524×4000 or as you required | |

| Color | Yellow/Green/Grey or as per client requirement |

| We provide Customized Services. Other sizes can be customized as per client requirement. |

| Free cutting. Cut into any shape for free. |

| Covered grating can be customized upon your request. The thickness of cover is available in 3mm and 5mm. |

| SURFACE | ||||

Meniscus: It provides superior slip resistance in most environments except barefoot traffic.  Grit: It provides secure footing for maximum safety. Aqua grit provides optimum comfort and safety for barefoot traffic.  Smooth: It creates a surface with a smooth finish after sanded down. |

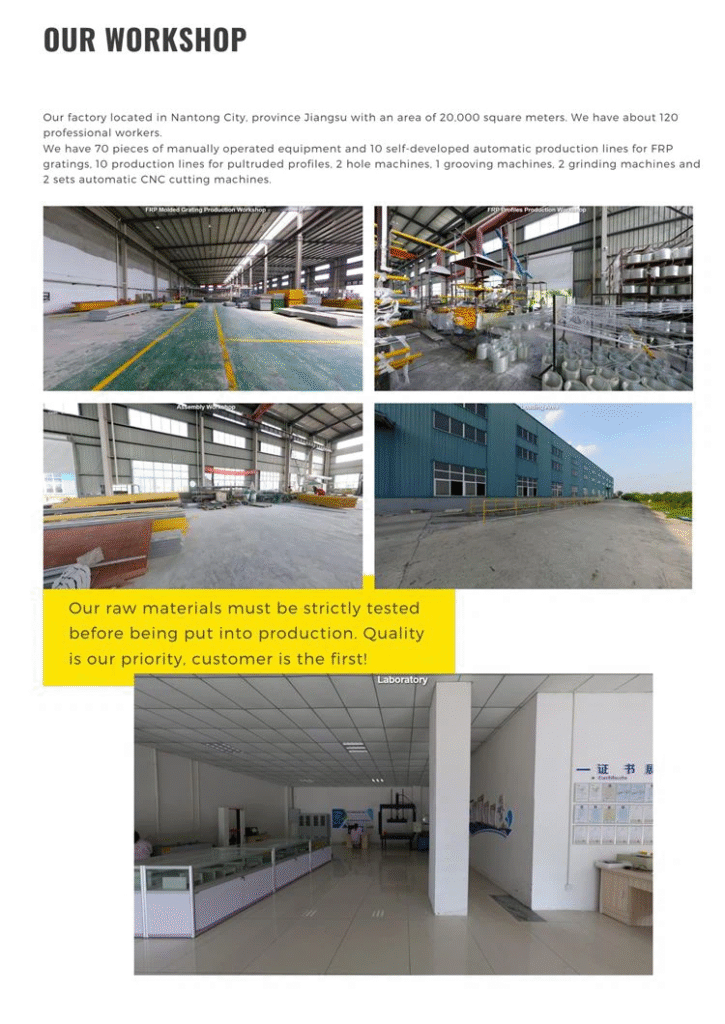

Q1: How do you ensure the quality of FRP products?

A: All products are manufactured in our own factory under strict ISO-based quality control. We perform raw material testing, process monitoring, and final inspection to ensure every panel meets strength, durability, and corrosion-resistance requirements.

Q2: Where can FRP products be used?

FRP products are ideal for chemical plants, wastewater facilities, offshore platforms, walkways, platforms, stairs, and other areas that require corrosion resistance, lightweight structure, and long service life.

Q3: Do you provide after-sales support?

Yes. We provide clear documentation, installation guidelines (if needed), and technical support. If any quality issue is confirmed after delivery, we offer replacement, rework, or other agreed solutions.

Q4: Can you help with project-specific requirements?

Absolutely. Our team can suggest the right resin system, grating type, and surface finish for your application, and provide drawings or design assistance to ensure project success.

Related Products

相关产品

T-Bar 1″Deep 50%Open(T10-50)

FRP GratingT-Bar 1 1/2″Deep 17%Open(T15-17)

FRP GratingT-Bar 1 1/2″Deep 17%Open(T15-17)

FRP Grating1 1/2″ Deep×1″×6″ SuperSpan

FRP Grating1 1/2″ Deep×3/4″ Mini Mesh

FRP Grating1/2″ Deep×1 1/2″ Square Mesh

FRP Grating1″ Deep×1 1/2″ Square Mesh

FRP GratingT-Bar 1″Deep 40%Open(T10-40)

FRP Grating