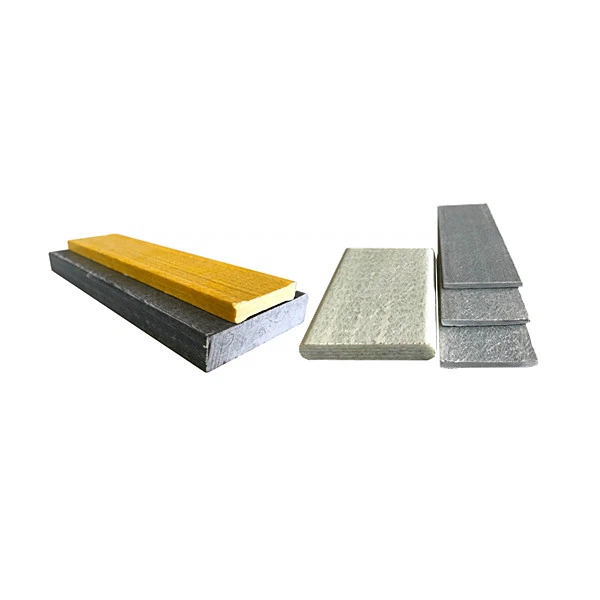

Fiberglass Flat Rods

Fiberglass angle iron is a strip profile with two sides perpendicular to each other, which is divided into equal leg angle iron and unequal leg angle iron.

Mach’s fiberglass angle iron is equal leg.

Accept Customized Service

A Choice of RAL Colors Available

- Customizable Options – Tailored size, resin type, and surface finish to meet your project needs.

- Factory-Direct Pricing – Save costs with direct production from our source factory.

- Free Sample Design – Get a sample or design validation before bulk production.

- Global Quality Supply – Reliable quality and on-time delivery worldwide.

Whether under normal conditions or high frequency conditions, fiberglass flat rods maintain good dielectric properties while the strength is comparable to alloy steel. Therefore, it has made outstanding contributions in aviation, rockets, space vehicles, high-pressure vessels, and other applications that require weight reduction.

Fiberglass flat rod is resistant to the atmosphere, water, general concentrations of acid, alkali, salt and a variety of oils and solvents. It has been applied to all aspects of chemical anticorrosion, and is replacing carbon steel, stainless steel, wood, non-ferrous metals, etc.

◆ Classification of fiberglass flat rod

▽ Conventional fiberglass flat rod

It can replace carbon steel, stainless steel and non-ferrous metals to be used in aviation, rockets. Longer fiberglass flat rods are usually used in structures just like in greenhouse framing.

▽ Bendable fiberglass flat rod

It has flexibility, and is the most worth buying. It is very suitable on variation of projects with that requires more flexibility and sturdiness.

| Raw material | Gass fiber(as reinforcement) Resin(as binder) Fiberglass cloth(as wrapping reinforcement) |

| Width | 12-300mm |

| Thickness | 4-20mm |

| Length | Unlimited |

| Surface treatment | Smooth and bright |

| Production process | Pultrusion |

| Color | A choice of RAL colors available |

◆ Common size of Mach’s fiberglass flat rods

Unit: mm

| Model No. | Size Width×Thickness | Weight |

| FS20 | 20×6.4 | 0.25kg/m |

| FS30A | 30×3.0 | 0.17kg/m |

| FE30B | 30×6.4 | 0.36kg/m |

| FS38 | 38×5.0 | 0.36kg/m |

| FS50A | 50×3.0 | 0.26kg/m |

| FS50B | 50×4.0 | 0.38kg/m |

| FS50C | 50×8.0 | 0.76kg/m |

| FS50D | 50×15.0 | 1.43kg/m |

| FS60 | 60×4.0 | 0.46kg/m |

| FS70 | 70×4.0 | 0.53kg/m |

| FS90 | 90×15.0 | 2.57kg/m |

| FS120 | 120×3.0 | 0.69kg/m |

| FS190 | 190×15.0 | 5.42kg/m |

| FS280 | 280×10.0 | 5.32kg/m |

Q1: How do you ensure the quality of FRP products?

A: All products are manufactured in our own factory under strict ISO-based quality control. We perform raw material testing, process monitoring, and final inspection to ensure every panel meets strength, durability, and corrosion-resistance requirements.

Q2: Where can FRP products be used?

FRP products are ideal for chemical plants, wastewater facilities, offshore platforms, walkways, platforms, stairs, and other areas that require corrosion resistance, lightweight structure, and long service life.

Q3: Do you provide after-sales support?

Yes. We provide clear documentation, installation guidelines (if needed), and technical support. If any quality issue is confirmed after delivery, we offer replacement, rework, or other agreed solutions.

Q4: Can you help with project-specific requirements?

Absolutely. Our team can suggest the right resin system, grating type, and surface finish for your application, and provide drawings or design assistance to ensure project success.

Related Products

相关产品

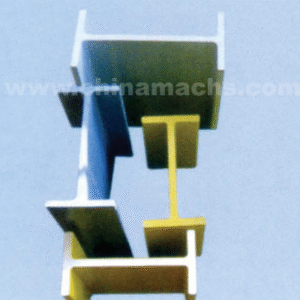

Word beam

FRP ProfilesAngle steel

FRP ProfilesPipe

FRP ProfilesSquare Fiberglass Rod

FRP ProfilesHigh strength bearing deck

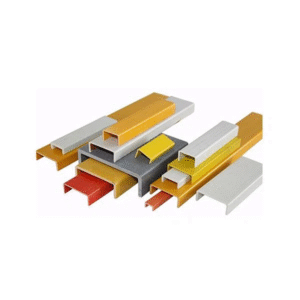

FRP ProfilesFRP C Channel

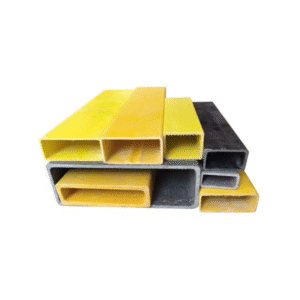

FRP ProfilesFiberglass Rectangular Tube

FRP ProfilesFiberglass Round Tube

FRP Profiles