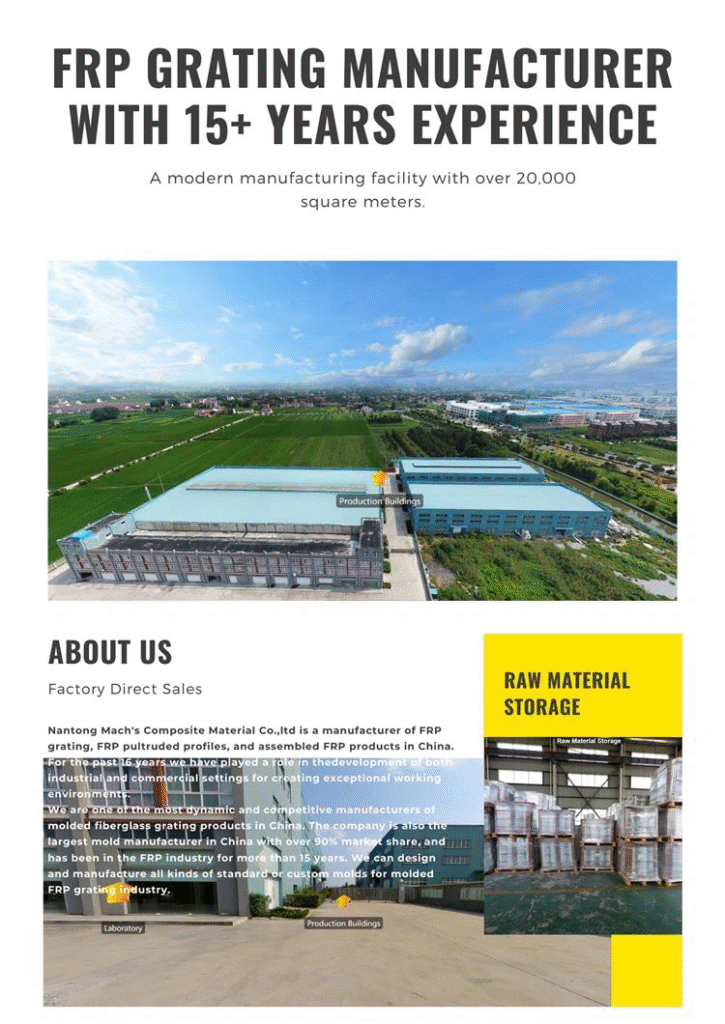

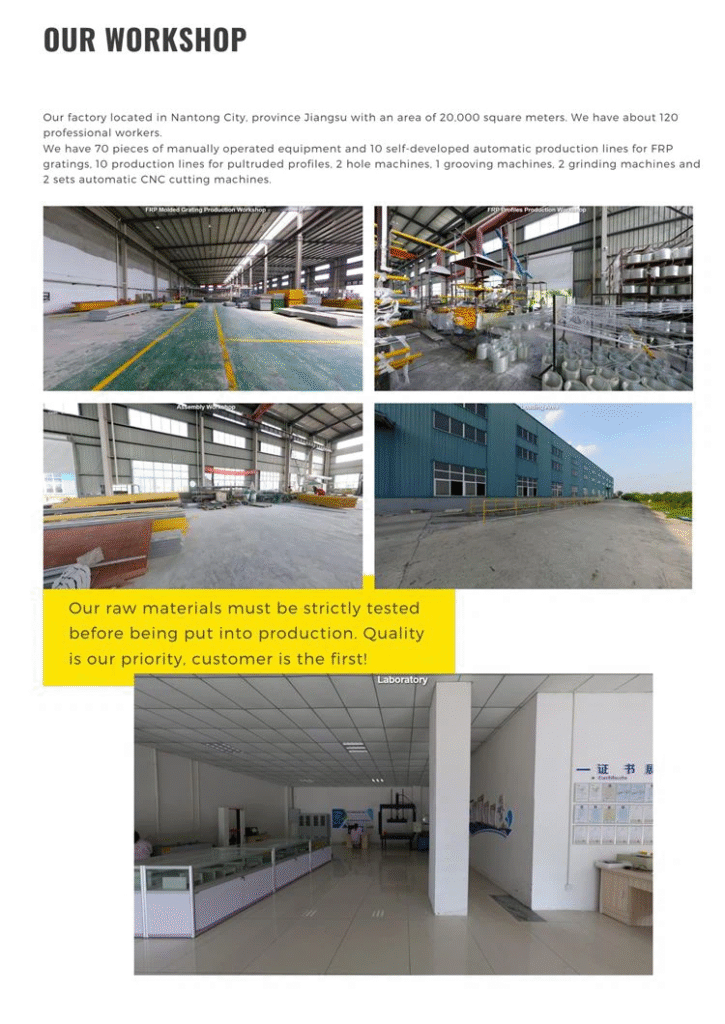

Fiberglass Angle Iron

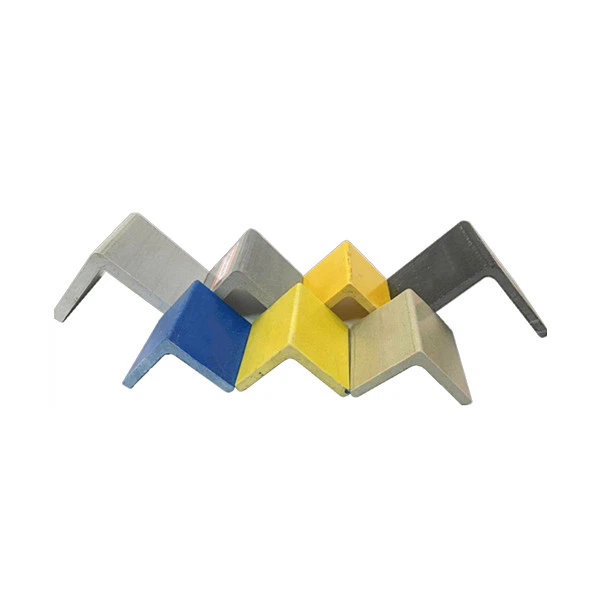

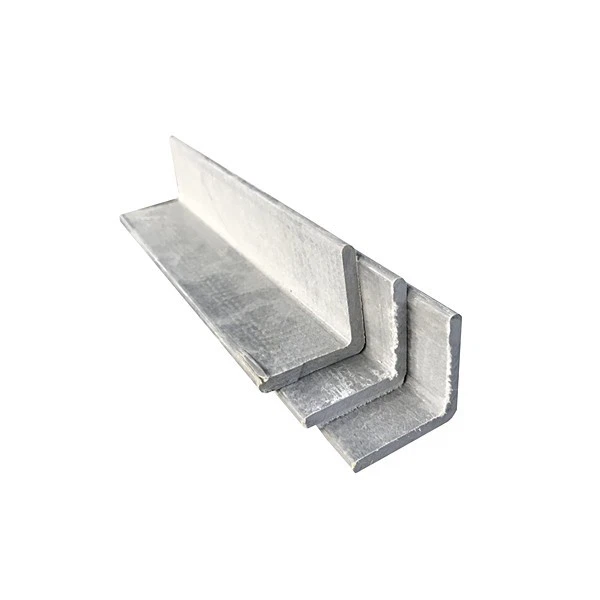

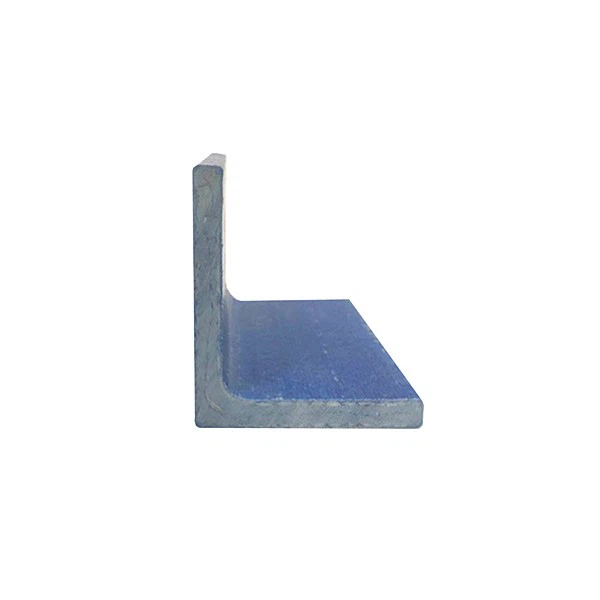

Fiberglass angle iron is a strip profile with two sides perpendicular to each other, which is divided into equal leg angle iron and unequal leg angle iron.

Mach’s fiberglass angle iron is equal leg.

Accept Customized Service

A Choice of RAL Colors Available

- Customizable Options – Tailored size, resin type, and surface finish to meet your project needs.

- Factory-Direct Pricing – Save costs with direct production from our source factory.

- Free Sample Design – Get a sample or design validation before bulk production.

- Global Quality Supply – Reliable quality and on-time delivery worldwide.

Fiberglass angle iron can be composed of different force support elements according to different needs of the structure, and can also be used as the connector between components. Its glass fiber content is higher than other composite materials, so the longitudinal strength is fairly high, which is equivalent to steel.

Fiberglass angle iron is one of the pultruded fibreglass profiles. Pultrusion is a special process in the composite material forming process. The advantages are below:

1.The production process is completely controlled by automation, with high production efficiency.

2.The fiber content of the fiberglass angle is up to 80%. The dipping is carried out under tension, which can give full play to the effect of fiber reinforcement.

3.The longitudinal and transverse strength of the fiberglass angle iron can be adjusted arbitrarily, which can meet the application requirements of products with different mechanical properties.

4.There is no corner waste in the production process, no need for post-processing, so it saves labor, materials, and energy consumption compared with other processes.

5.The quality of the pultruded fibreglass profiles is stable and the length can be cut at will.

Our fiberglass angle iron ranges are manufactured in accordance with BS EN 13706. As part of this specification, all angles with wall thicknesses between 3 and 5mm meet the E17 performance class, while angles with wall thicknesses greater than 5mm achieve the higher performance E23 class.

◆ Common size of Mach’s fiberglass angle iron

| Model No. | Size A B C | Weight |

| L38A | 38×38×4.8 | 0.65kg/m |

| L38B | 38×38×6.4 | 0.85kg/m |

| L50A | 50×50×3.2 | 0.59kg/m |

| L50B | 50×50×6.4 | 1.14kg/m |

| L76A | 76×76×3.2 | 0.91kg/m |

| L76B | 76×76×4.8 | 1.34kg/m |

| L76C | 76×76×6.4 | 1.77kg/m |

| L76D | 76×76×9.5 | 2.57kg/m |

| L176E | 76×76×12.7 | 3.36kg/m |

| L101A | 101v101×6.4 | 2.38kg/m |

| L101B | 101×101×8.0 | 2.95kg/m |

| L101C | 101×101×9.5 | 3.48kg/m |

| L101D | 101×101×12.7 | 4.57kg/m |

| L152A | 152×152×6.4 | 3.62kg/m |

| L152B | 152×152×9.5 | 5.32kg/m |

| L152C | 152×152×12.7 | 7.03kg/m |

Q1: How do you ensure the quality of FRP products?

A: All products are manufactured in our own factory under strict ISO-based quality control. We perform raw material testing, process monitoring, and final inspection to ensure every panel meets strength, durability, and corrosion-resistance requirements.

Q2: Where can FRP products be used?

FRP products are ideal for chemical plants, wastewater facilities, offshore platforms, walkways, platforms, stairs, and other areas that require corrosion resistance, lightweight structure, and long service life.

Q3: Do you provide after-sales support?

Yes. We provide clear documentation, installation guidelines (if needed), and technical support. If any quality issue is confirmed after delivery, we offer replacement, rework, or other agreed solutions.

Q4: Can you help with project-specific requirements?

Absolutely. Our team can suggest the right resin system, grating type, and surface finish for your application, and provide drawings or design assistance to ensure project success.

Related Products

相关产品

Angle steel

FRP ProfilesSolid party great、Solid round rods

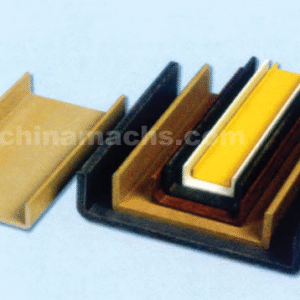

FRP ProfilesFiberglass Angle Shapes

FRP ProfilesChannel steel

FRP ProfilesFiberglass Round Bar

FRP ProfilesH beams

FRP ProfilesFRP Round Tube

FRP ProfilesFRP Square Tube

FRP Profiles