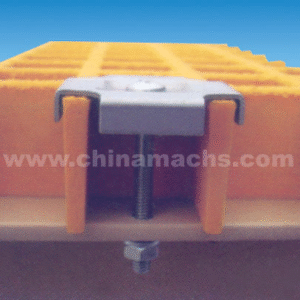

Clamp Fastener

- Customizable Options – Tailored size, resin type, and surface finish to meet your project needs.

- Factory-Direct Pricing – Save costs with direct production from our source factory.

- Free Sample Design – Get a sample or design validation before bulk production.

- Global Quality Supply – Reliable quality and on-time delivery worldwide.

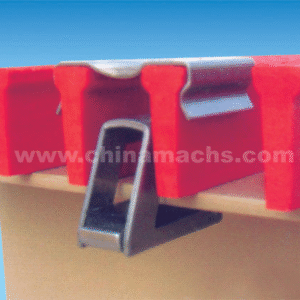

Clamp fastener

Clamp fastener is used to install FRP gratings, FRP handrail, ladder and FRP platform. Clamp fastener has high strength and corrosion resistance due to its material of 316/304 stainless steel. Clamp fastener has different shape, according to its shape, clamp fastener be divided into M clip, G clip, C clip, L clip, Paw clip, W clip, T clip, CSSM clips. Different shape is used in different application.

Description

Main features:

1, High strength

2, Corrosion resistance

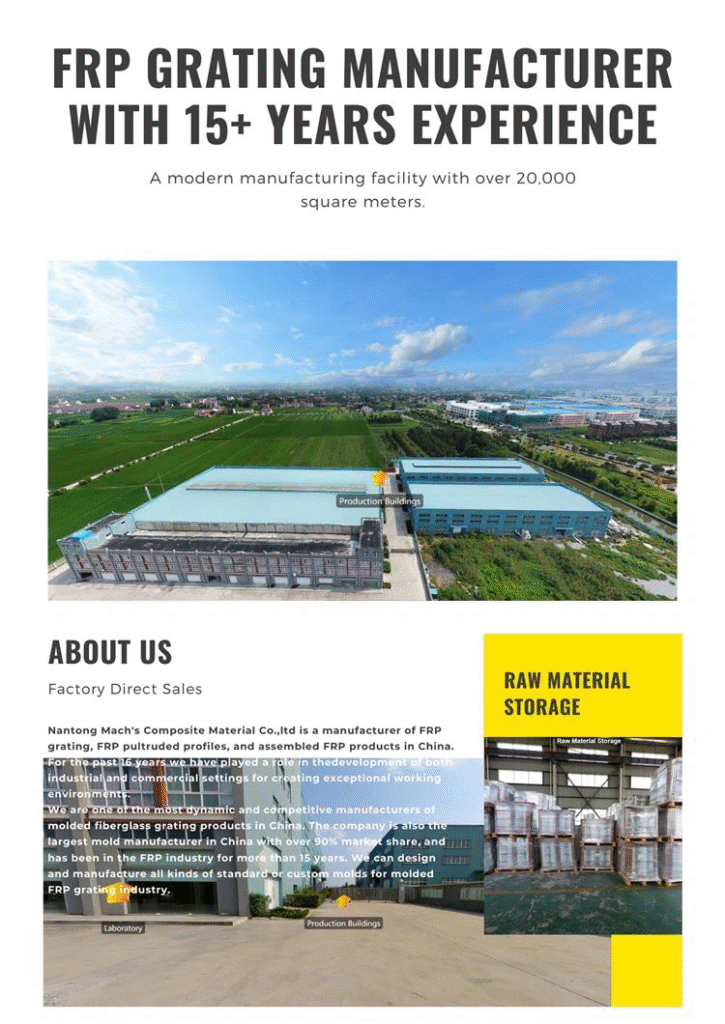

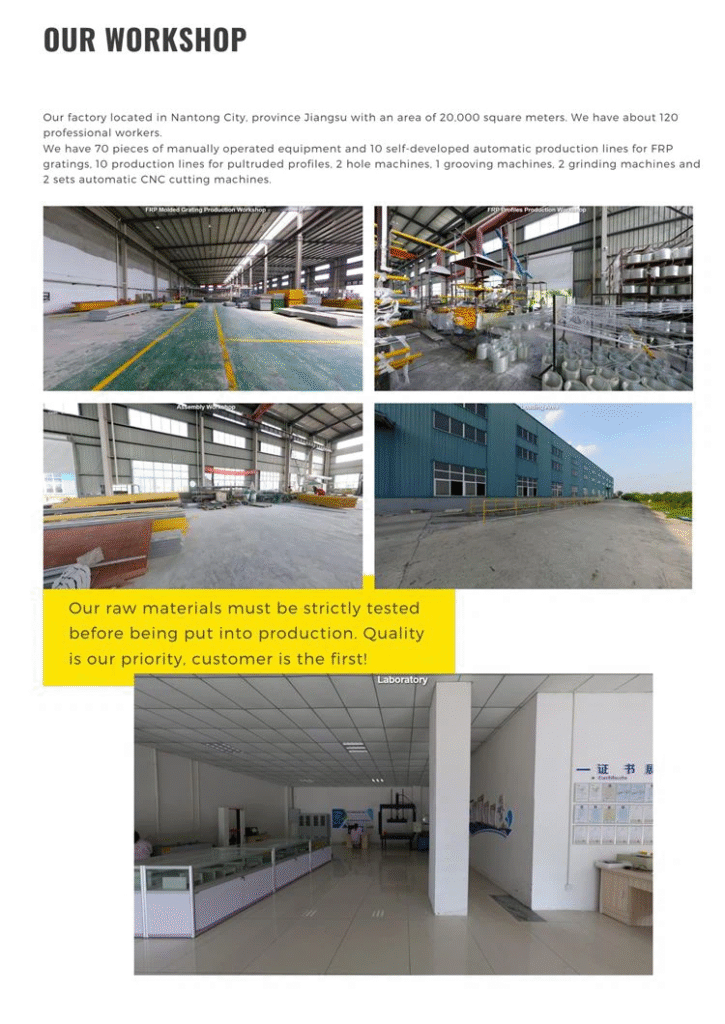

About our company

1. We are a professional manufacturer of molded FRP products with more than 15 years’ experience in this field.

2. Our molded FRP products are of high quality and competitive price. We have approved by ISO, ABS, SGS, ASTM E84.

3. We have an professional sales team.

4. We have over 100 professional workers and great production capacity.

5. We provide products with high quality and good after-sale services.

6. Our FRP products are well acknowledged by many countries, such as USA, England, Germany, etc.

As there are many clips for grating connection, different clips may be used in different situation. Please tell us your requirements, we will advise you suitable clip for your application. Our beautiful price and excellent service will not disappoint you. Start to get free samples now.

Q1: How do you ensure the quality of FRP products?

A: All products are manufactured in our own factory under strict ISO-based quality control. We perform raw material testing, process monitoring, and final inspection to ensure every panel meets strength, durability, and corrosion-resistance requirements.

Q2: Where can FRP products be used?

FRP products are ideal for chemical plants, wastewater facilities, offshore platforms, walkways, platforms, stairs, and other areas that require corrosion resistance, lightweight structure, and long service life.

Q3: Do you provide after-sales support?

Yes. We provide clear documentation, installation guidelines (if needed), and technical support. If any quality issue is confirmed after delivery, we offer replacement, rework, or other agreed solutions.

Q4: Can you help with project-specific requirements?

Absolutely. Our team can suggest the right resin system, grating type, and surface finish for your application, and provide drawings or design assistance to ensure project success.

Related Products

相关产品

G clips Grating Fasteners

Grating ClipsC Clamp

Grating ClipsL Clamp

Grating ClipsC Clips

Grating ClipsPAW Clips

Grating ClipsCSSM Clips – Plan A

Grating ClipsFiberglass Grating Fasteners

Grating ClipsFRP Grating C Clips 38x38mm

Grating Clips