25mm GRP Grating

25mm GRP grating has a lower load capacity and is generally used for human walking. In addition, it is often used as a walkway, floor, cargo rack, etc. in water treatment plants and electroplating plants.

Accept Customized GRP Gratings

A Choice of RAL Colors Available

- Customizable Options – Tailored size, resin type, and surface finish to meet your project needs.

- Factory-Direct Pricing – Save costs with direct production from our source factory.

- Free Sample Design – Get a sample or design validation before bulk production.

- Global Quality Supply – Reliable quality and on-time delivery worldwide.

25mm GRP grating has relatively low load carrying capacity compared with other thickness gratings, and its load-bearing range is about 1 ton. The common mesh size of the 25mm GRP molded grating is 38X38mm, and the whole pannel size is 1524×4000mm,1220×3660mm and 1220×2440mm. The most commonly used 25mm GRP pultruded gratings are I4010, I5010 and I6010.

Due to the general carrying capacity of 25mm GRP grating, it is usually used in:

◆ Municipal greening tree pond and tree pit cover

◆ Pedestrian drainage ditch and trench cover

◆ Factory walkway, inspection channel, floor and cargo rack

◆ Solar photovoltaic power generation pedal, photovoltaic roof walkway

◆ Farms (chicken, duck, goose, pigeon, sheep, rabbit) Fecal leakage plates, leakage plates, nursery beds

Common Sizes of 25mm GRP Grating

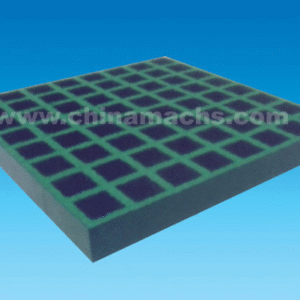

GRP molded grating

Unit: mm

| Thickness | Mesh Size | Load Bar Thickness(Top/Bottom) | Available Panel Size | Open Area | Weight |

| 25 | 38×38 | 6.4/5.0 | 1524×4000 1220×4000 1220×3660 1220×2440 915×3050 | 68% | 12.30kg/m2 |

| 40×40 | 7.0/5.0 | 1247×4047 1007×4047 1007×3007 | 67% | 12.30kg/m2 | |

| 50×50 | 7.5/6.0 | 1220×3660 1220×2440 915×3050 | 78% | 11.50kg/m2 | |

| 83×83 | 7.0/5.0 | 1007×4007 1007×3007 | 84% | 5.80kg/m2 | |

| 19×19/38×38 mini mesh | 6.5/5.0 | 1524×4000 1220×4000 1220×3660 1220×2440 915×3050 | 40% | 16.80kg/m2 | |

| 25×100 | 7.0/5.5 | 1007×3007 | 67% | 13.00kg/m2 | |

| 25×100 | 6.5/5.0 | 1220×3660 | 67% | 13.83kg/m2 |

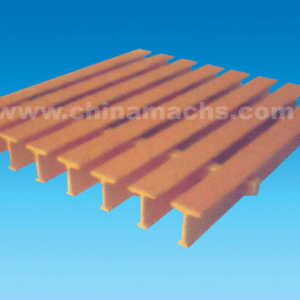

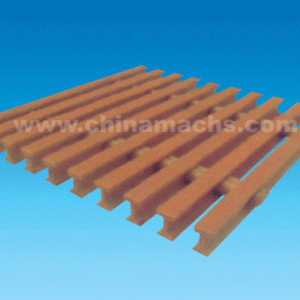

GRP pultruded grating

Unit: mm

| Thickness | Model No. | Pultrusion Beam Size(Top/Bottom) | Open Area | Weight(with CD tip) | Weight(with three core pin) |

| 25 | I4010 | 15/15 | 40% | 15.6kg/m2 | 17.1kg/m2 |

| I5010 | 15/15 | 50% | 12.7kg/m2 | 14.2kg/m2 | |

| I6010 | 15/15 | 60% | 9.7kg/m2 | 11.2kg/m2 | |

| T1210 | 38/15 | 12% | / | 14.5kg/m2 | |

| T1810 | 41.3/15 | 18% | / | 13.8kg/m2 | |

| T2510 | 38/15 | 25% | / | 12.3kg/m2 | |

| T3310 | 41.3/15 | 33% | / | 11.2kg/m2 | |

| T3810 | 38/15 | 38% | / | 10.2kg/m2 |

In addition to the above common sizes, if you have special requirements, please contact us immediately, we have experienced engineers and workers to customize for you.

Product Details

Q1: How do you ensure the quality of FRP products?

A: All products are manufactured in our own factory under strict ISO-based quality control. We perform raw material testing, process monitoring, and final inspection to ensure every panel meets strength, durability, and corrosion-resistance requirements.

Q2: Where can FRP products be used?

FRP products are ideal for chemical plants, wastewater facilities, offshore platforms, walkways, platforms, stairs, and other areas that require corrosion resistance, lightweight structure, and long service life.

Q3: Do you provide after-sales support?

Yes. We provide clear documentation, installation guidelines (if needed), and technical support. If any quality issue is confirmed after delivery, we offer replacement, rework, or other agreed solutions.

Q4: Can you help with project-specific requirements?

Absolutely. Our team can suggest the right resin system, grating type, and surface finish for your application, and provide drawings or design assistance to ensure project success.

Related Products

相关产品

T-Bar 1″Deep 18%Open(T10-18)

FRP Grating1 1/2″ Deep×1 1/2″ Square Mesh

FRP GratingT-Bar 1″Deep 40%Open(T10-40)

FRP Grating1/2″ Deep×1 1/2″ Square Mesh

FRP GratingT-Bar 1 1/2″Deep 33%Open(T15-33)

FRP Grating2″ Deep×2″ Square Mesh

FRP Grating1″ Deep×1 1/2″ Square Mesh

FRP GratingT-Bar 1″Deep 50%Open(T10-50)

FRP Grating