FRP (Fiberglass Reinforced Plastic) is now widely used in chemical plants, wastewater systems, and industrial projects.

It’s strong, lightweight, and resistant to corrosion.

But not all FRP products are built the same.

Some last for over ten years, while others fail after only a few.

This article explains what makes a high-quality FRP product and how to choose the right one for your project.

1. High Strength-to-Weight Ratio

A good FRP product combines light weight with strong performance.

Compared to steel or aluminum, FRP is easier to handle and install but still offers excellent load-bearing strength.

This means:

Lower transport and installation costs

Less stress on your building structure

More flexibility in design

When you choose FRP, ask for real test data like tensile and flexural strength. That tells you more than marketing words.

2. Corrosion and Chemical Resistance

High-quality FRP stands up to tough environments.

It can handle acids, salt, and humidity that quickly damage metal.

The key lies in the resin system — such as polyester, vinyl ester, or epoxy — which defines how well the FRP resists chemicals.

Before buying, check if your supplier provides a chemical resistance chart or examples of similar field applications.

This helps you confirm whether the FRP can truly perform in your environment.

3. Long Service Life with Low Maintenance

FRP does not rust, peel, or need painting.

It performs well outdoors under sunlight, moisture, and temperature changes.

For operators, this means:

Less maintenance work

Lower labor costs

Fewer shutdowns and repairs

If downtime costs you money, FRP’s low maintenance advantage quickly pays for itself.

4. Design Flexibility and Customization

High-quality FRP can be tailored to your project.

You can adjust size, wall thickness, color, and surface finish.

Experienced manufacturers design FRP around your actual use:

Load capacity

Chemical exposure

Installation space

Operating temperature

Simply put, a good FRP manufacturer doesn’t sell standard panels — they build around your process.

5. Safety and Compliance

Safety always matters in industrial projects.

High-quality FRP products are made to meet recognized standards such as ASTM, ISO, or UL.

They often include:

Anti-slip surfaces

Fire-retardant or insulating properties

UV and impact resistance

Ask for test reports or certifications to ensure the product meets your safety needs.

6. Cost Efficiency Over Time

While FRP may cost more upfront, it saves you money over time.

Its long lifespan and low maintenance make it more economical than steel or aluminum.

You’ll save by:

Avoiding corrosion repairs and repainting

Reducing labor and downtime

Extending service life

High-quality FRP is not the cheapest at first — it’s the most cost-effective in the long run.

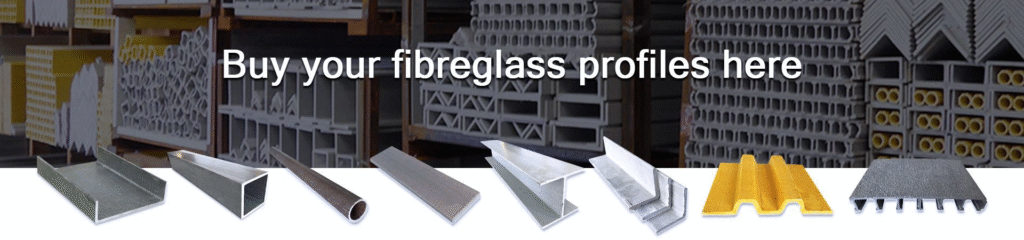

7. Choosing the Right FRP Partner

The best FRP products come from experienced manufacturers who understand both materials and real-world applications.

Quality depends on more than just the raw components — it’s about:

Good materials, smart design, precise manufacturing, and strict testing.

At Machs, we create FRP systems built for real industrial conditions.

From gratings and handrails to platforms and tanks, our solutions combine strength, corrosion resistance, and long-term reliability to help you build safer, stronger facilities.

In Summary

High-quality FRP is defined by performance, not by price.

A reliable FRP product should be:

Lightweight and strong

Corrosion-resistant and long-lasting

Safe, customizable, and certified

Cost-efficient over its service life

By focusing on these factors, you can choose FRP products that deliver better performance and greater value for years to come.