Fiberglass Reinforced Plastic (FRP) is widely recognized for its high strength, light weight, and superior corrosion resistance. It’s used across industries such as chemical processing, marine engineering, wastewater treatment, and infrastructure.

However, many clients still ask:

“Can FRP really handle long-term exposure to sunlight, heat, or harsh chemicals?”

This article takes a closer, evidence-based look at FRP’s behavior under UV radiation, high temperature, and chemical exposure, and explains how to optimize its performance in demanding environments.

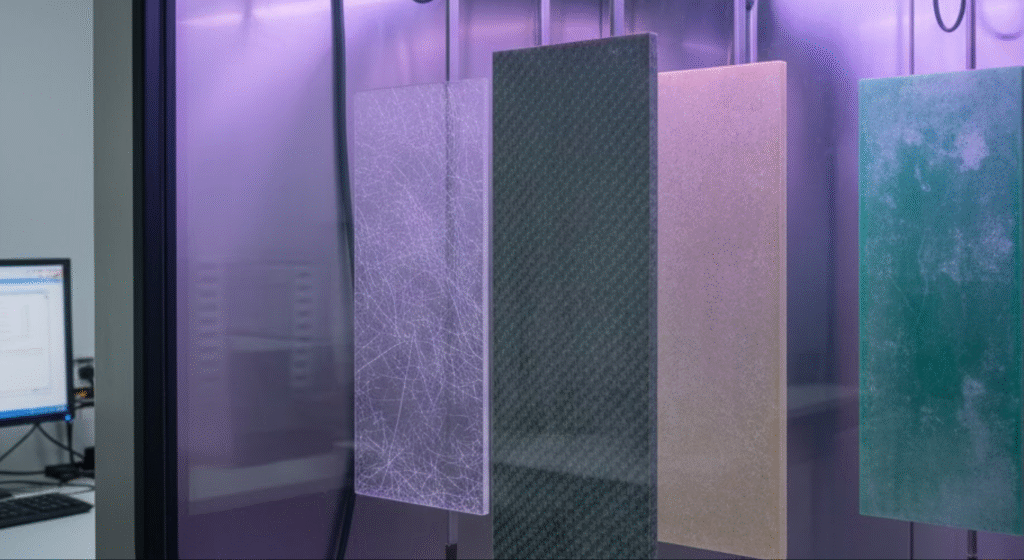

UV Resistance and Outdoor Durability

Ultraviolet radiation is one of the main external factors that cause material degradation.

In FRP, the glass fibers are naturally UV-stable, while the resin matrix may show signs of surface oxidation, such as color fading or slight chalking, after prolonged exposure.

Some users worry: “Does fading mean the structure is weakening?”

Fortunately, the answer is no — these are mostly cosmetic changes. The internal strength and stiffness of FRP remain largely unaffected.

To improve UV resistance, manufacturers often:

Use UV-stabilized resin systems (such as vinyl ester or phenolic resins)

Apply a gel coat layer or UV-resistant coating

Use color pigments with high lightfastness for outdoor parts

In summary:

FRP maintains its structural integrity under sunlight. Proper surface protection can extend its outdoor lifespan for many years with minimal maintenance.

Heat Resistance and Temperature Stability

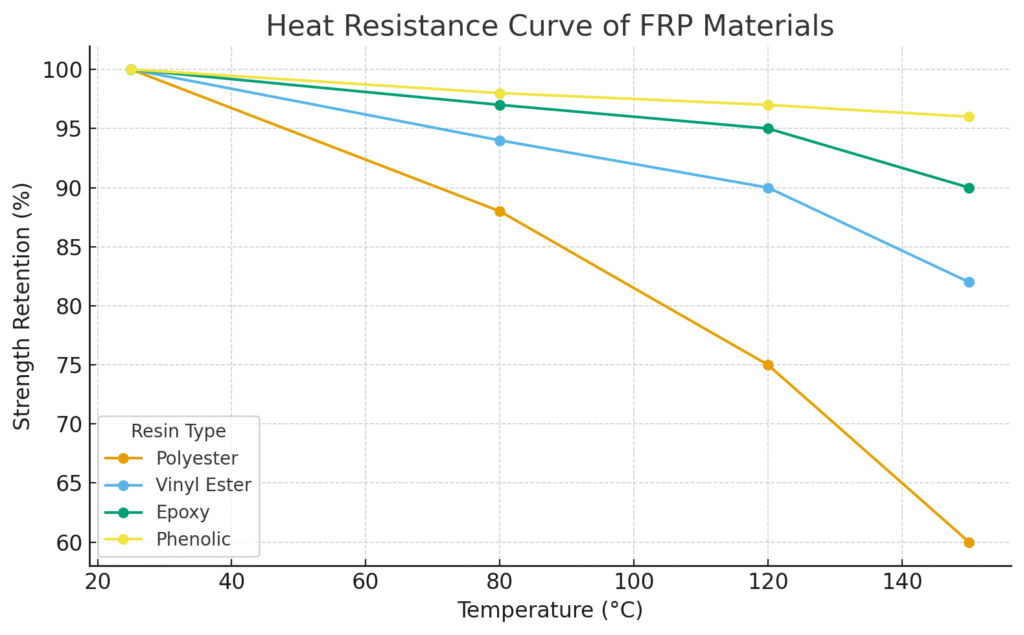

Phenolic and Epoxy resins show excellent heat resistance, Vinyl Ester remains stable up to 120 °C, and Polyester weakens quickly under high heat.

The heat resistance of FRP mainly depends on the resin system.

Unlike metals, FRP does not deform due to thermal expansion or suffer from rust, but as the temperature approaches the resin’s glass transition temperature (Tg), its rigidity may gradually decrease.

| Resin Type | Recommended Service Temp (°C) | Strength Retention at 120°C | Typical Application |

|---|---|---|---|

| Polyester | ≤80 | 75% | General industrial gratings |

| Vinyl Ester | ≤120 | 90% | Chemical flooring, tanks |

| Epoxy | ≤130 | 95% | Structural beams, ladders |

| Phenolic | ≤180 | 97% | Fire-resistant decks, marine |

Engineers often ask: “Can FRP be used near heat sources or furnaces?”

Yes — as long as the right resin is selected. Epoxy and phenolic systems retain over 90% of their strength even at 150 °C.

Heat Resistance Curve of FRP Materials

Phenolic and epoxy resins show the best performance at elevated temperatures. Vinyl ester remains stable under moderate heat, while polyester, though cost-effective, is better suited for indoor or normal-temperature applications.

Overall, FRP can operate safely between -40 °C and 120 °C, while high-performance systems can tolerate up to 180 °C without significant loss of strength.

Chemical Resistance and Corrosion Protection

One of FRP’s most significant advantages is its exceptional resistance to chemical attack.

The resin matrix forms a dense protective barrier that effectively prevents acids, alkalis, salts, and oils from penetrating the material.

| Chemical Type | Resistance Level | Recommended Resin |

|---|---|---|

| Acids (H₂SO₄, HCl) | Excellent | Vinyl Ester / Phenolic |

| Alkalis (NaOH) | Good | Epoxy / Vinyl Ester |

| Saltwater | Excellent | Polyester / Vinyl Ester |

| Organic Solvents | Fair | Epoxy |

| Oil & Grease | Good | Polyester |

Someone might ask: “So FRP is completely corrosion-proof?”

Not entirely — strong oxidizing chemicals like concentrated nitric acid can cause minor surface degradation, but structural integrity remains intact.

When properly specified, FRP structures can withstand aggressive chemical environments for over a decade with little to no maintenance — far outperforming steel or aluminum.

Long-Term Durability and Maintenance

Once installed, FRP structures require minimal upkeep.

Routine cleaning and occasional inspections are typically sufficient.

If the surface layer shows signs of weathering, a quick gel coat reapplication can restore protection and appearance.

In many chemical and marine projects, FRP components operate reliably for 10 years or more without major repairs.

This long service life, combined with low maintenance cost, makes FRP a practical choice for demanding environments.

Conclusion

FRP demonstrates remarkable stability under UV, heat, and chemical exposure:

UV Exposure: Minor surface fading, but no structural loss

Heat Exposure: Stable up to 120 °C; high-grade resins resist up to 180 °C

Chemical Resistance: Outstanding corrosion protection across most industrial media

Durability: Long lifespan with low maintenance requirements

Thanks to these advantages, FRP has become an ideal material for outdoor, high-temperature, and corrosive applications, offering a balance of strength, cost-efficiency, and long-term reliability.

By selecting the appropriate resin system and surface protection, engineers can ensure FRP structures deliver consistent performance — even in the harshest operating conditions.