Welcome to Machs Laboratory

To ensure consistent product quality and compliance with international standards, we operate a fully equipped in-house laboratory with advanced testing instruments

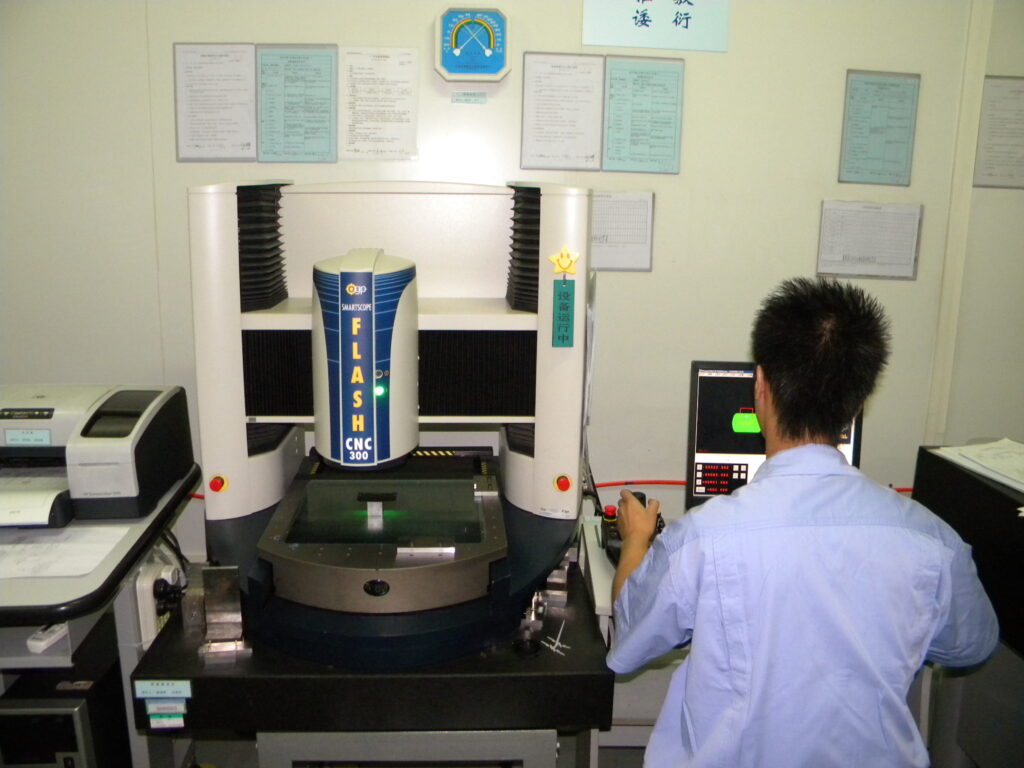

CNC Vision Measuring System

Used for high-precision dimensional inspection of molded gratings, pultruded profiles, and accessories. This system ensures that every hole, slot, and edge meets strict design tolerances, preventing assembly errors and guaranteeing smooth installation on site.

Salt Spray Tester (ASTM B117 / ISO 9227)

Recreates aggressive salt fog and marine atmospheres to evaluate long-term corrosion resistance. This test helps predict performance in coastal, offshore, and chemical plant environments where corrosion is a critical safety factor.

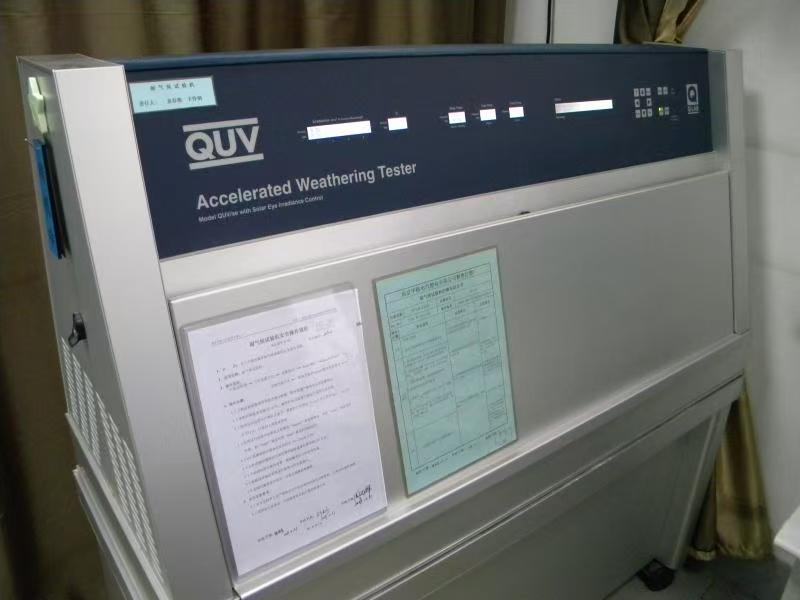

QUV Accelerated Weathering Tester (ASTM G154 / G155)

Simulates years of outdoor exposure within weeks by alternating UV light and moisture cycles. It allows us to assess colorfastness, surface chalking, and gloss retention to ensure products maintain appearance and durability over time.

Profile Projector

Magnifies and measures complex shapes, angles, and machined features of smaller components. This guarantees that connectors, fasteners, and custom fittings match precisely with the grating panels or profiles they are designed for.

Universal Tensile & Flexural Testing Machine (ASTM D638 / D790)

Measures tensile strength, flexural strength, and modulus of elasticity. These results verify that our FRP materials consistently achieve the required load-bearing capacity and safety margins specified in engineering standards.

Impact Tester (ASTM D256)

Determines the ability of FRP to absorb sudden energy or shock loads. This is critical for walkways, platforms, and stair treads used in heavy-traffic areas or subjected to accidental impacts.

Coordinate Measuring Machine (CMM)

Provides 3D dimensional verification of molds, jigs, and finished profiles. This ensures that production tools are perfectly aligned and that products remain consistent across large production runs.

Constant Temperature & Humidity Chamber

Exposes samples to controlled high/low temperature and humidity to evaluate dimensional stability and mechanical property changes. This test demonstrates the material’s performance in tropical or highly variable climates.

Thermal Shock & Temperature Cycling Chamber

Rapidly alternates between extreme hot and cold conditions to replicate real-world thermal cycling. It helps predict potential material fatigue, micro-cracking, or deformation over years of service.