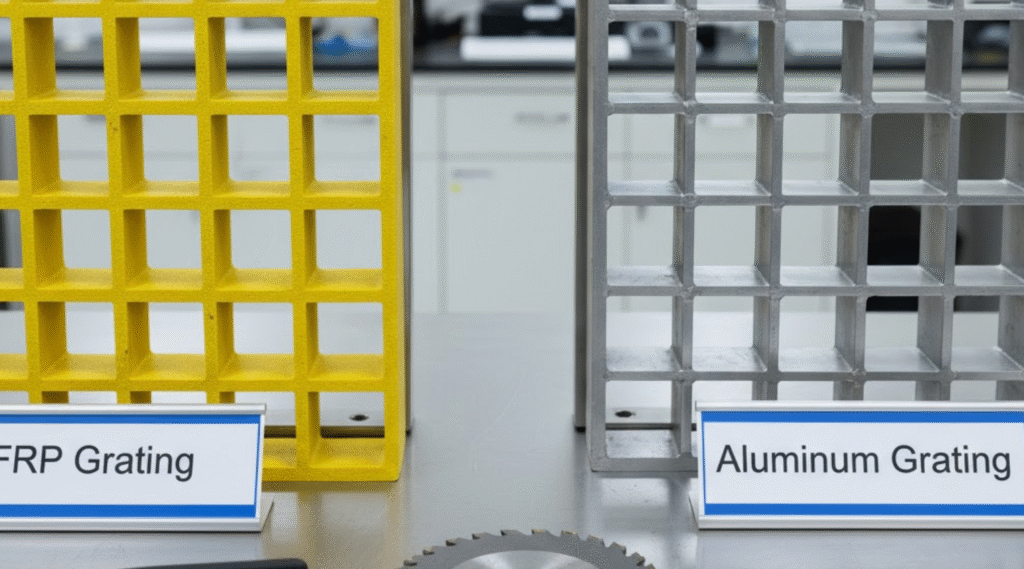

In industrial flooring and platform applications, both FRP (Fiberglass Reinforced Plastic) grating and aluminum grating are popular choices. At first glance, they may look similar, but their performance, maintenance, and long-term costs differ significantly. This article compares FRP and aluminum gratings from multiple aspects to help you select the right material for your project.

Corrosion Resistance

FRP grating has excellent corrosion resistance due to its composite material made from fiberglass and resin. It performs well in chemical plants, wastewater treatment, and marine environments where moisture and corrosive gases are present.

Aluminum grating, while resistant to rust, can still corrode under exposure to chlorides or acidic conditions. Over time, oxidation may cause a dull surface or pitting, especially in coastal or industrial atmospheres.

👉 Verdict: FRP grating wins in harsh or chemical-heavy environments.

Strength-to-Weight Ratio

FRP gratings are remarkably lightweight — around one-fourth the weight of steel and significantly lighter than aluminum — while maintaining strong load-bearing capacity.

Aluminum gratings also provide good strength but are still heavier and less flexible compared to FRP, which offers better impact resistance and elasticity.

👉 Verdict: FRP gratings provide an ideal balance of strength and lightweight structure, making transportation and installation easier.

Thermal and Electrical Properties

One of the biggest advantages of FRP is its non-conductivity. It does not transmit electricity or heat, ensuring higher safety in electrical plants and offshore platforms.

Aluminum, on the other hand, is a highly conductive metal. This makes it unsuitable for certain electrical environments where insulation and safety are priorities.

👉 Verdict: FRP grating is safer for applications requiring electrical or thermal insulation.

Maintenance and Service Life

FRP gratings require minimal maintenance. Their corrosion-resistant and non-metallic structure prevents rust, painting, or recoating needs.

Aluminum gratings, while relatively durable, often require surface treatment or anodizing to maintain their appearance and prevent corrosion in humid or chemical environments.

Cost Comparison

At first, FRP gratings may appear more expensive per square meter than aluminum. However, when considering installation labor, maintenance, and lifespan, FRP provides a much lower lifecycle cost.

Aluminum gratings are cheaper upfront but may incur higher maintenance or replacement expenses over time.

Applications

FRP Grating: Chemical plants, wastewater treatment facilities, offshore platforms, cooling towers, food processing areas, and walkways in corrosive environments.

Aluminum Grating: Lightweight walkways, stair treads, ventilation covers, or architectural decoration where corrosion exposure is limited.

Summary Table

| Comparison Aspect | FRP Grating | Aluminum Grating |

|---|---|---|

| Corrosion Resistance | Excellent (chemical & saltwater) | Moderate (can oxidize) |

| Weight | Very light | Light |

| Strength-to-Weight Ratio | High | Medium |

| Electrical Conductivity | Non-conductive | Conductive |

| Maintenance | Very low | Occasional treatment needed |

| Cost Efficiency | Higher long-term value | Lower initial cost |

| Recommended Use | Harsh, chemical, or wet environments | General or decorative use |

Conclusion

Both FRP and aluminum gratings have their unique advantages. If your project involves harsh environments, chemical exposure, or electrical safety concerns, FRP grating is the superior choice. For decorative or general indoor use, aluminum grating remains a practical and economical option.